Harmonic drive cam

A technology of harmonic drive and cam, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems such as limited variation range of cam wrap angle, poor load capacity of harmonic drive, and severe stress change of flexible wheel, etc. Achieve the effect of high transmission efficiency, curve speed mutation point, and easy production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The present invention will be described with reference to the accompanying drawings.

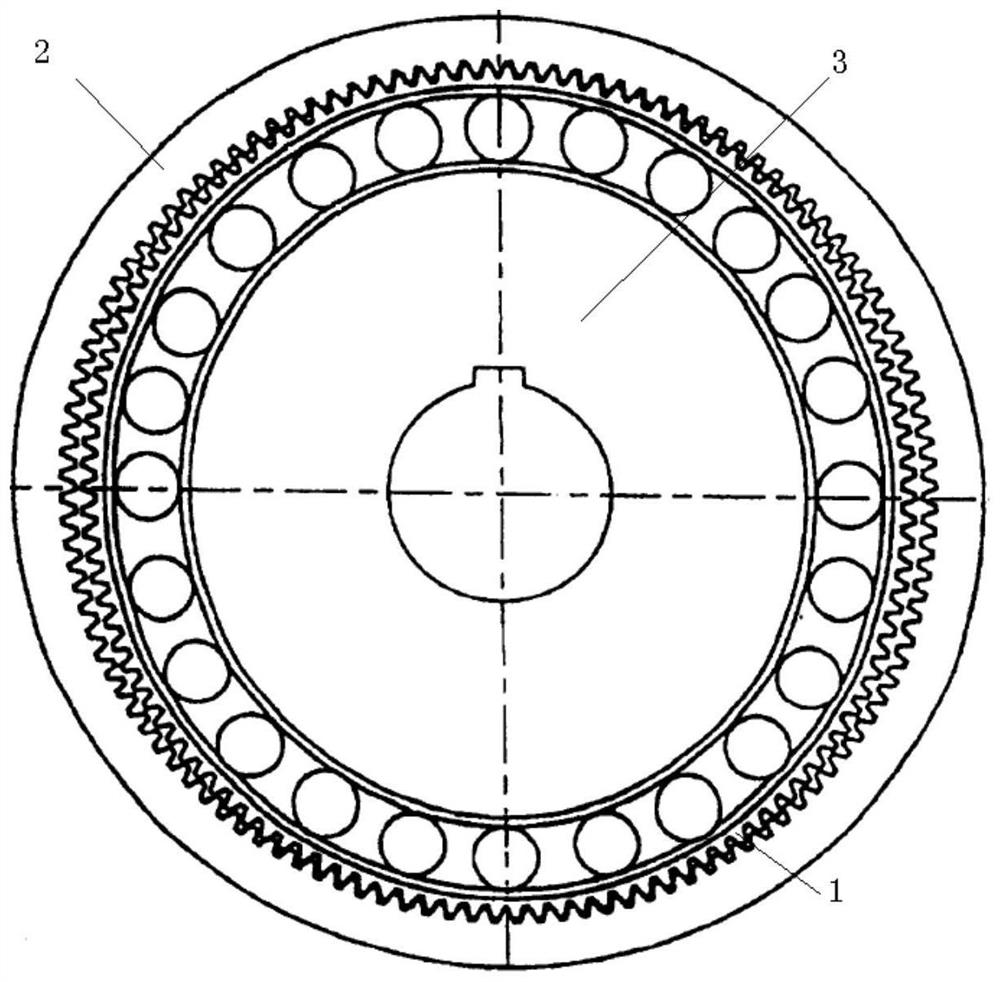

[0020] like figure 1 , the harmonic gear transmission pair includes a flexible wheel 1, a rigid wheel 2, and a cam 3, wherein the cam 3 is a shock source that generates harmonic drive fluctuations.

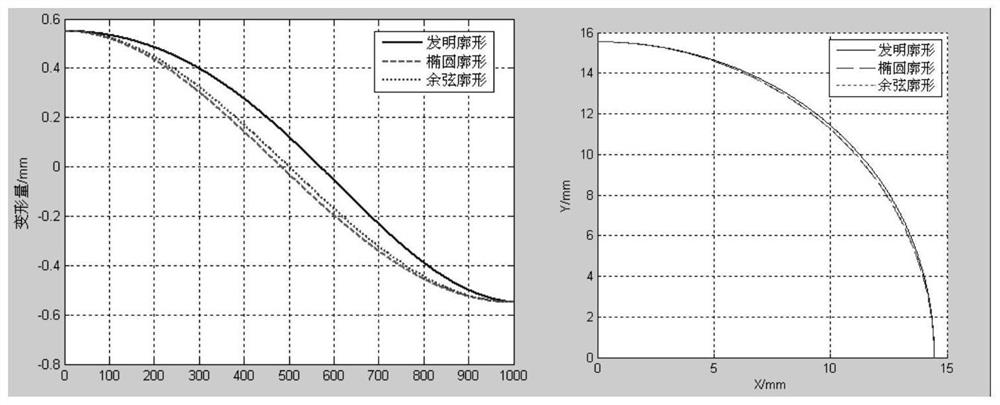

[0021] Based on the original cosine cam characteristic curve, the present invention adds low angular frequency and high angular frequency cosine waves to adjust the cam wrap angle range, so that the characteristic curve changes slowly near the long axis of the cam, and the closer it is to the short axis of the cam, the greater the change Violently, the bearing capacity of the harmonic drive is enhanced, the equivalent ball load is reduced, and the service life of the flexible bearing is improved. figure 2 It is a comparison chart of the cam characteristic curve.

[0022] The cam characteristic curve equation is:

[0023] ρ=R+A×cos(θ)+B×cos(2θ)+C×cos(4θ);

[0024] Among them: where, θ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com