Resistance-free check valve with energy-saving effect for power station

A non-resistance, power station technology, applied in the direction of functional valve types, valve details, control valves, etc., can solve problems such as poor protection, troublesome check valve operation, poor lubrication effect, etc., and achieve surface anti-sticking effect Excellent, smooth movement, good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

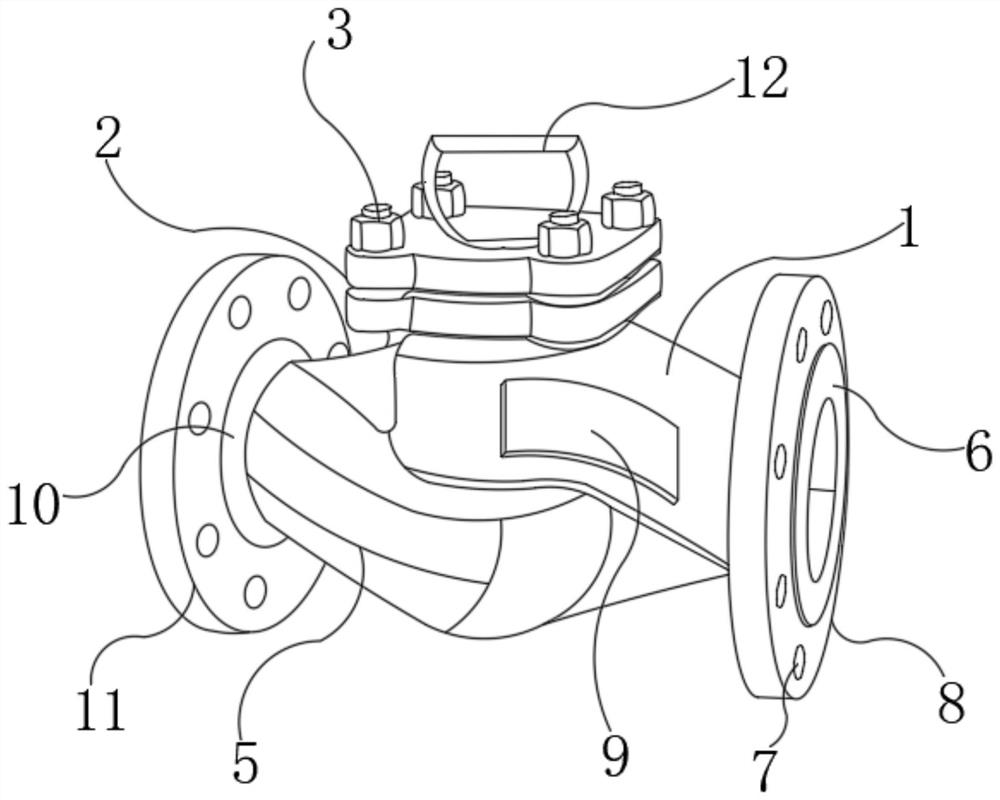

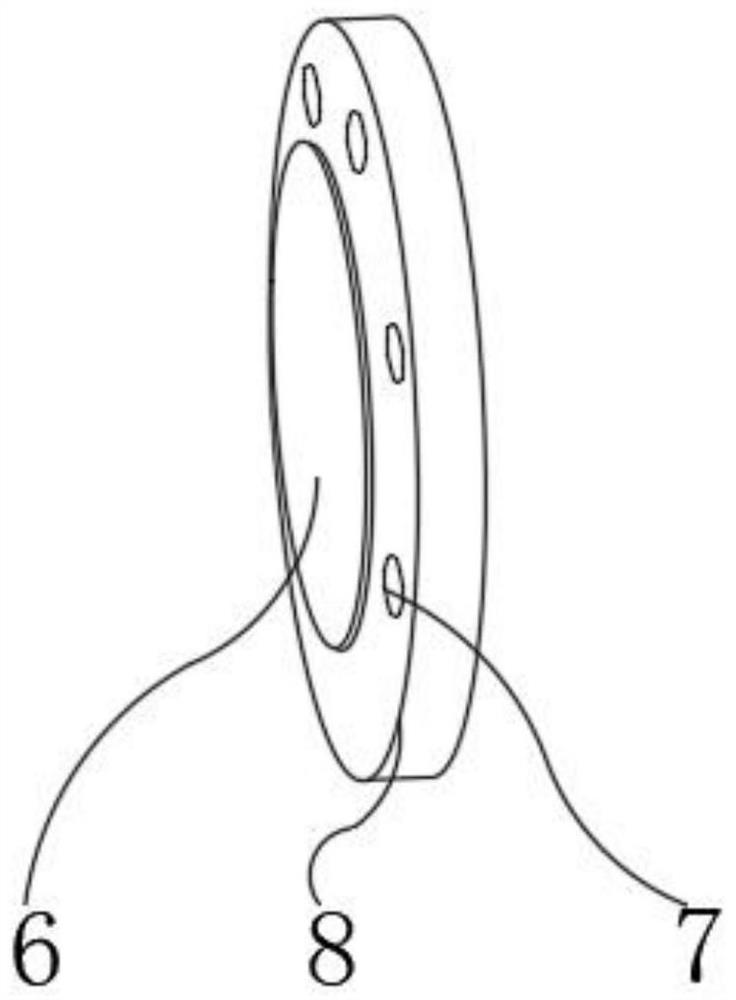

[0025] Such as Figure 1-4 As shown, a non-resistance check valve with energy-saving effect for power stations includes a valve body 1, the inner wall of the valve body 1 is fixedly connected with a reinforced anti-corrosion and anti-sticking mechanism 5, and one side of the valve body 1 is fixedly connected with a No. Install the valve seat 8, the other side of the valve body 1 is fixedly connected with the second installed valve seat 11, the inner wall of the first installed valve seat 8 is provided with a flow port 6, and the outer surface of the first installed valve seat 8 is provided with a positioning flange 7. A multi-functional monitoring mechanism 9 is installed on the outer side of the valve body 1. A welding block 10 is fixedly connected between the valve body 1 and the second installed valve seat 11. The upper end of the valve body 1 is installed with a mounting seat 2, and the mounting seat 2 The upper end of the valve is equipped with a lifting ring 12, the four...

Embodiment 2

[0028] On the basis of Example 1, as figure 1 , 5 As shown, a non-resistance check valve with energy-saving effect for power stations includes a valve body 1, the inner wall of the valve body 1 is fixedly connected with a reinforced anti-corrosion and anti-sticking mechanism 5, and one side of the valve body 1 is fixedly connected with a No. Install the valve seat 8, the other side of the valve body 1 is fixedly connected with the second installed valve seat 11, the inner wall of the first installed valve seat 8 is provided with a flow port 6, and the outer surface of the first installed valve seat 8 is provided with a positioning flange 7. A multi-functional monitoring mechanism 9 is installed on the outer side of the valve body 1. A welding block 10 is fixedly connected between the valve body 1 and the second installed valve seat 11. The upper end of the valve body 1 is installed with a mounting seat 2, and the mounting seat 2 A lifting ring 12 is installed on the upper end...

Embodiment 3

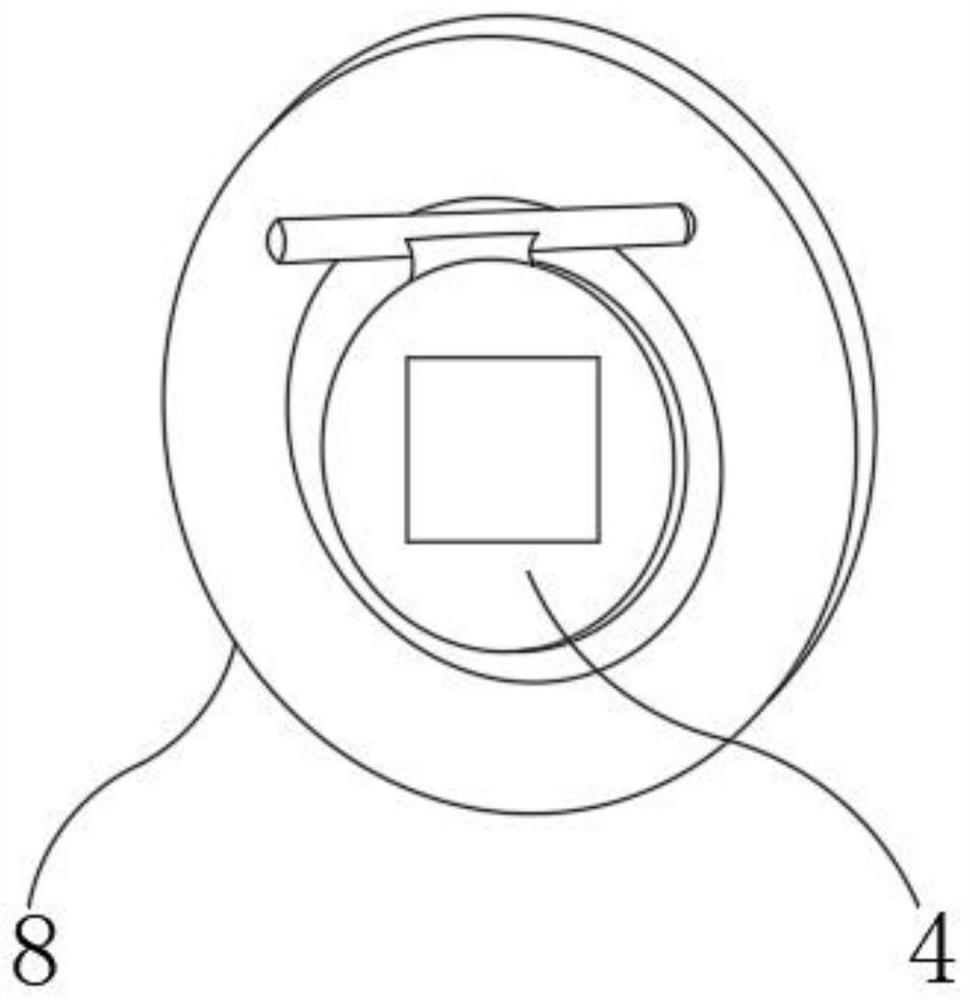

[0032] On the basis of Example 2, such as figure 1 , 6 As shown, a non-resistance check valve with energy-saving effect for power stations includes a valve body 1, the inner wall of the valve body 1 is fixedly connected with a reinforced anti-corrosion and anti-sticking mechanism 5, and one side of the valve body 1 is fixedly connected with a No. Install the valve seat 8, the other side of the valve body 1 is fixedly connected with the second installed valve seat 11, the inner wall of the first installed valve seat 8 is provided with a flow port 6, and the outer surface of the first installed valve seat 8 is provided with a positioning flange 7. A multi-functional monitoring mechanism 9 is installed on the outer side of the valve body 1. A welding block 10 is fixedly connected between the valve body 1 and the second installed valve seat 11. The upper end of the valve body 1 is installed with a mounting seat 2, and the mounting seat 2 A lifting ring 12 is installed on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com