Oil tank inner wall detection robot

A technology of robots and detection mechanisms, applied in the direction of supporting machines, instruments, mechanical equipment, etc., can solve the problems of low detection efficiency, high wall surface requirements, complex steering control, etc., and achieve high detection efficiency, simple control process, and tank wall requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

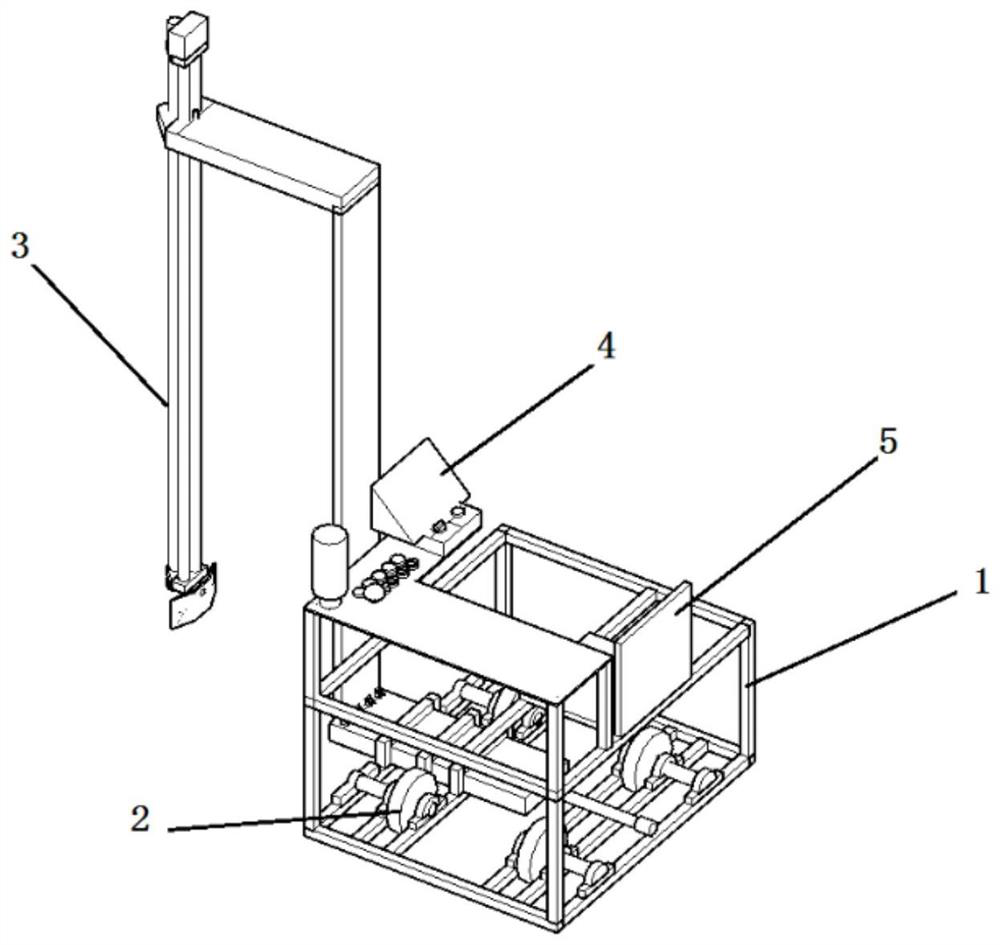

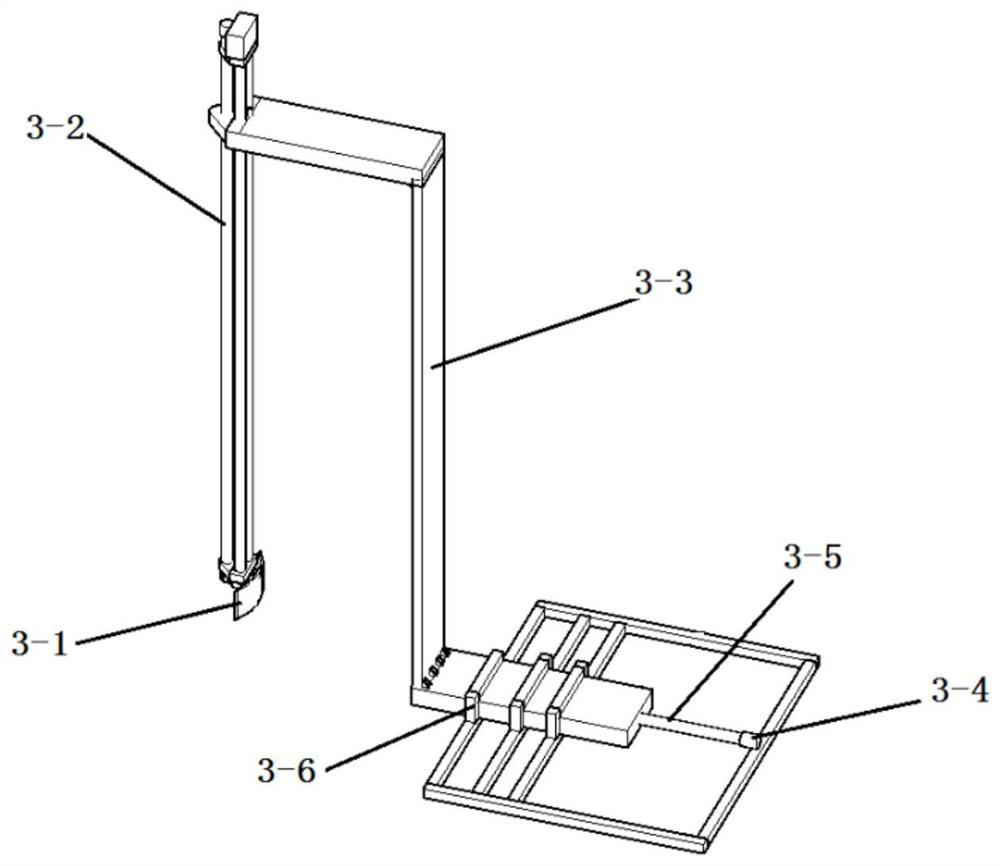

[0035] Embodiment 1 A detection robot for the inner wall of an oil tank, whose structure refers to figure 1 As shown, it includes a body 1, a walking steering mechanism 2, a lifting detection mechanism 3, a control system 4 and a seat 5. The walking steering mechanism 2 is located at the bottom of the body 1; the lifting detection mechanism 3 is located at one side of the body 1; the control system 4 is located at The upper part of the body 1; the seat 5 is located at the upper rear side of the body 1;

[0036] Among them, refer to Figure 7 As shown, the travel steering mechanism 2 includes four travel wheels 2-1 and four travel motors 2-4; the rotating shaft of the travel wheels 2-1 is installed in the support bearing 2-2, and the support bearing 2-2 is fixed on the body 1 ; The rotating shaft is connected with the travel motor 2-4 through the shaft coupling 2-3. The movement in different directions is realized by the different turning directions of the traveling motors 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com