Blasting equipment for water-spaced annular non-coupling charging in blast hole

A blasting equipment and spacer ring technology, applied in blasting and other directions, can solve the problems of inhomogeneous blasting effect, different degree of fragmentation of the hole wall, low degree of fragmentation at the water-filled place, etc., so as to reduce the energy of explosives, shorten the ventilation time, and improve the energy of explosives. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with embodiment.

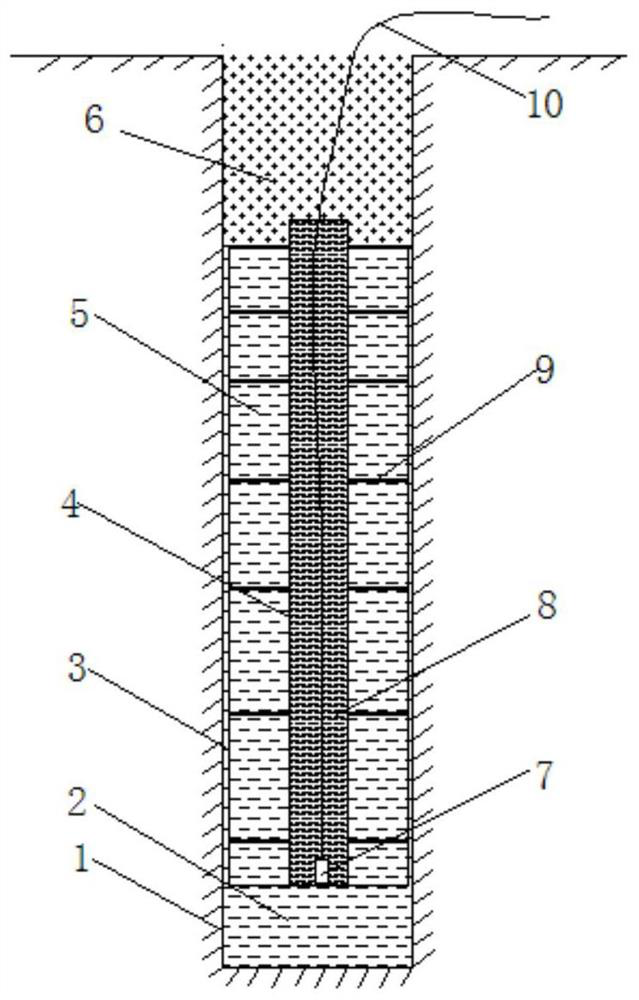

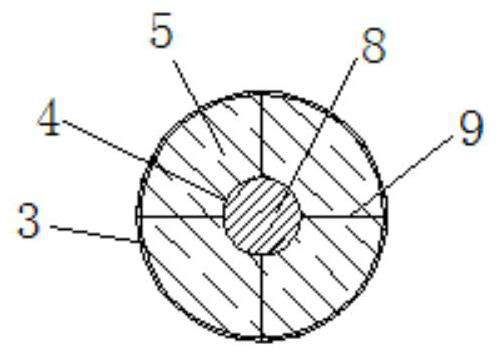

[0027] Such as figure 1 Shown: a blasting method in which the water jacket in the blast hole is not coupled with the circumferential direction, the blast hole is equipped with a double-layer casing, the explosive 8 is installed in the inner tube 4 of the double-layer casing, and the ring of the inner tube 4 and the outer tube 3 Water is filled in the gap, the inner layer of the double-layer casing is fixed at the inner center of the outer layer, and a water jacket is formed around the explosive after charging.

[0028] The double-layer casing is made of PVC material, and the bottom of the inner pipe 4 is closed.

[0029] A distance of 50-200 mm is reserved between the bottom of the inner tube 4 of the double-layer casing and the bottom of the blast hole.

[0030] In the double-layer casing, the bottom of the inner tube 4 is 50-200mm shorter than the outer tube 3 .

[0031] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com