Multi-station bar stretching robot and stretching method

A robot and multi-station technology, applied in the field of metal material stretching, can solve the problems of unstable deformation performance, inability to quickly achieve buffer effect, increase workload, etc., to prevent stability, alleviate reverse force, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following description, numerous specific details are set forth in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other instances, some technical features known in the art have not been described in order to avoid obscuring the present invention.

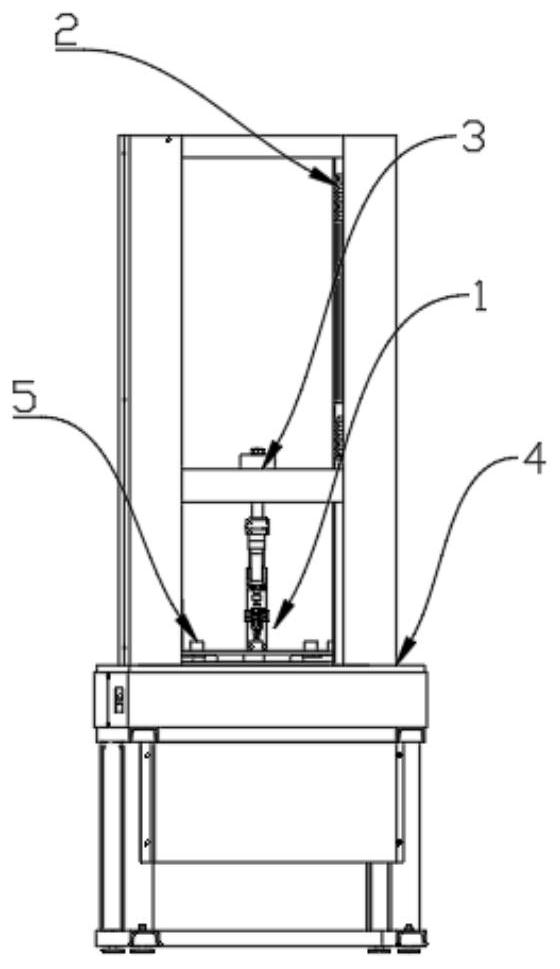

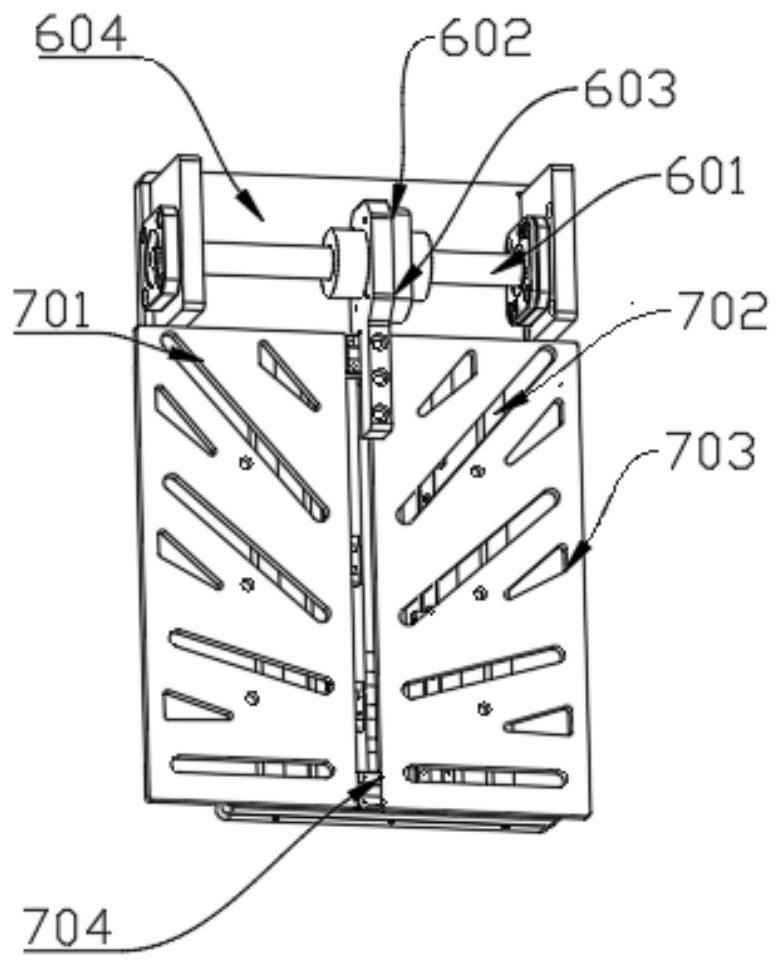

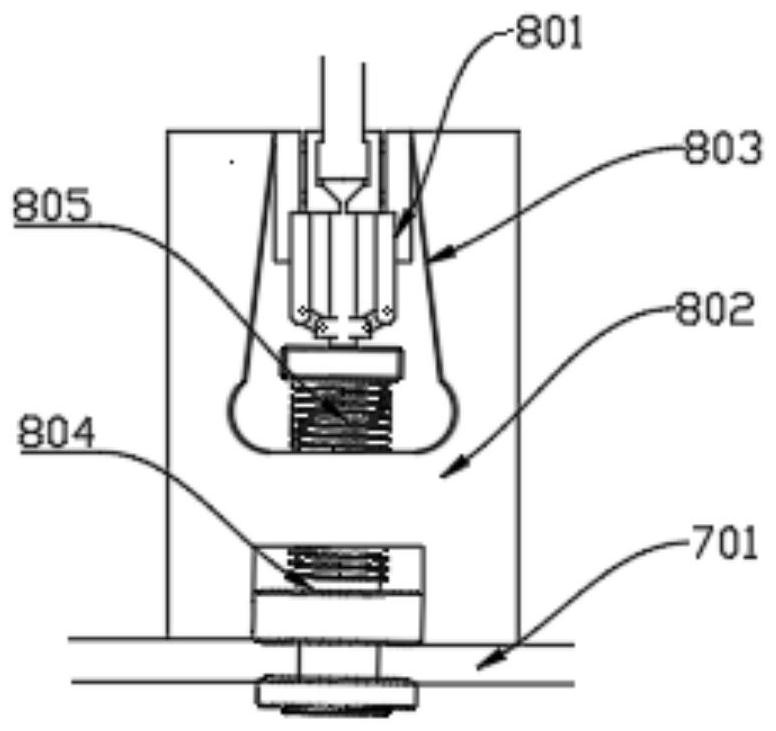

[0034]The invention relates to a multi-station bar stretching robot and a stretching method, such as Figure 1 to Figure 5 As shown, it includes four parts of frame 4, stretching mechanism 3, workbench 1 and transmission device 5, and the specific scheme is as follows:

[0035] Frame 4, a stretching mechanism 3 that moves horizontally and linearly along the frame 4, a workbench 1 that is fixed on the frame 4 and arranged parallel to the stretching mechanism 3; the frame 4 is fixedly provided with sliding The rail 2 makes the tensile mechanism 3 clamp the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com