Method for accelerating curing of lithium battery diaphragm

A lithium battery separator and accelerated aging technology, used in secondary batteries, electrochemical generators, battery pack components, etc. Effects of variables, reduction of wavy edge depth, optimization of aging environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

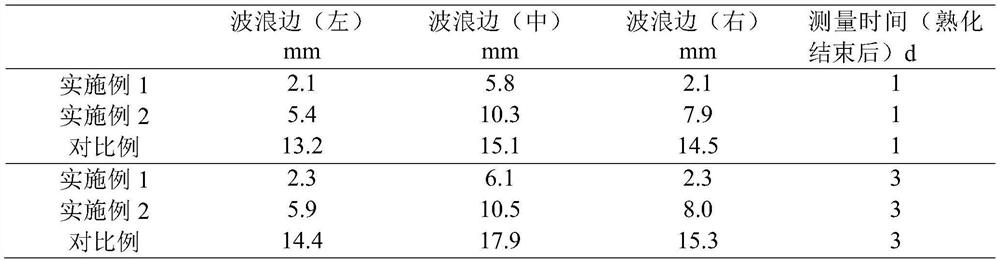

Examples

Embodiment 1

[0019] S1. Wrap the surface of the tube core with an outer diameter of 600mm with foam cotton cushioning material (EVA material), and roll the diaphragm with a width of 4000mm for the first time;

[0020] S2. Place the diaphragm wound in step S1 in an environment with a temperature of 43-45° C. and a humidity of 40%-45% for 2 hours for curing;

[0021] S3, the film processed in step S2 is slitting and rewinding, the outer diameter of the rewinding tube core is 203mm, and wrapping foam cotton cushioning material (EVA material);

[0022] S4. Put the separator wound up in step S3 into an environment with a temperature of 46-48° C. and a humidity of 30%-35% for 3 hours for curing.

Embodiment 2

[0024] S1. Wrap the surface of the tube core with an outer diameter of 600mm with foam cotton cushioning material (EVA material), and roll the diaphragm with a width of 4000mm for the first time;

[0025] S2. Place the diaphragm wound in step S1 in an environment with a temperature of 48-50° C. and a humidity of 30%-35% for 3 hours for curing;

[0026] S3, the film processed in step S2 is slitting and rewinding, the outer diameter of the rewinding tube core is 203mm, and wrapping foam cotton cushioning material (EVA material);

[0027] S4. Put the separator wound up in step S3 into an environment with a temperature of 50-52° C. and a humidity of 20%-25% for 4 hours for curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com