Spliced photovoltaic module

A photovoltaic module and splicing technology, which is applied in the field of electric power equipment, can solve the problems of low installation efficiency, achieve the effects of increasing work efficiency, facilitating centralized installation and placement, and facilitating power conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

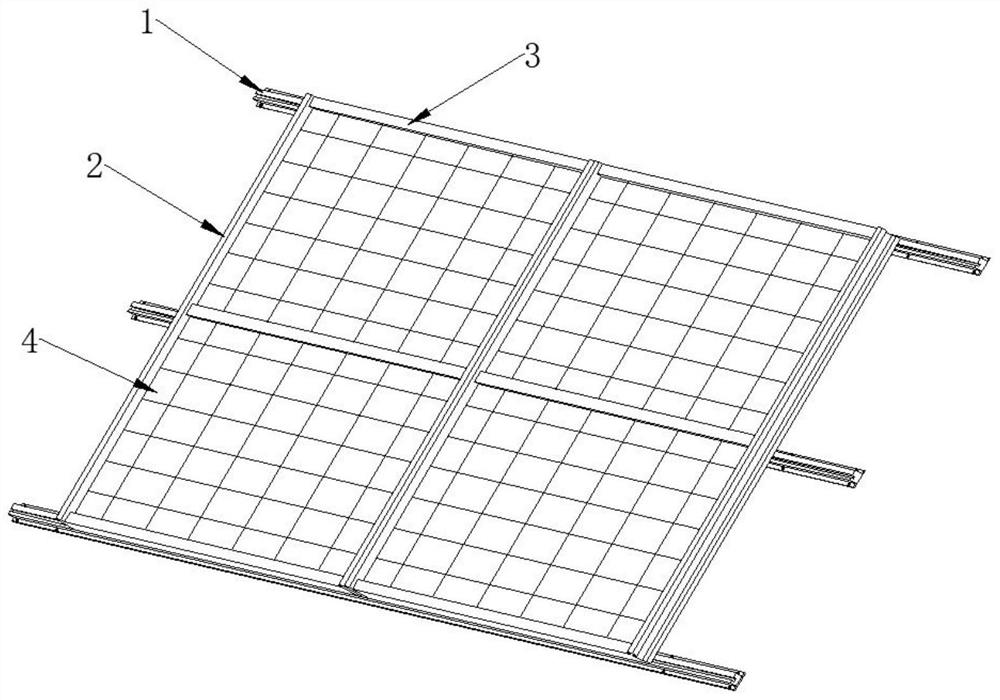

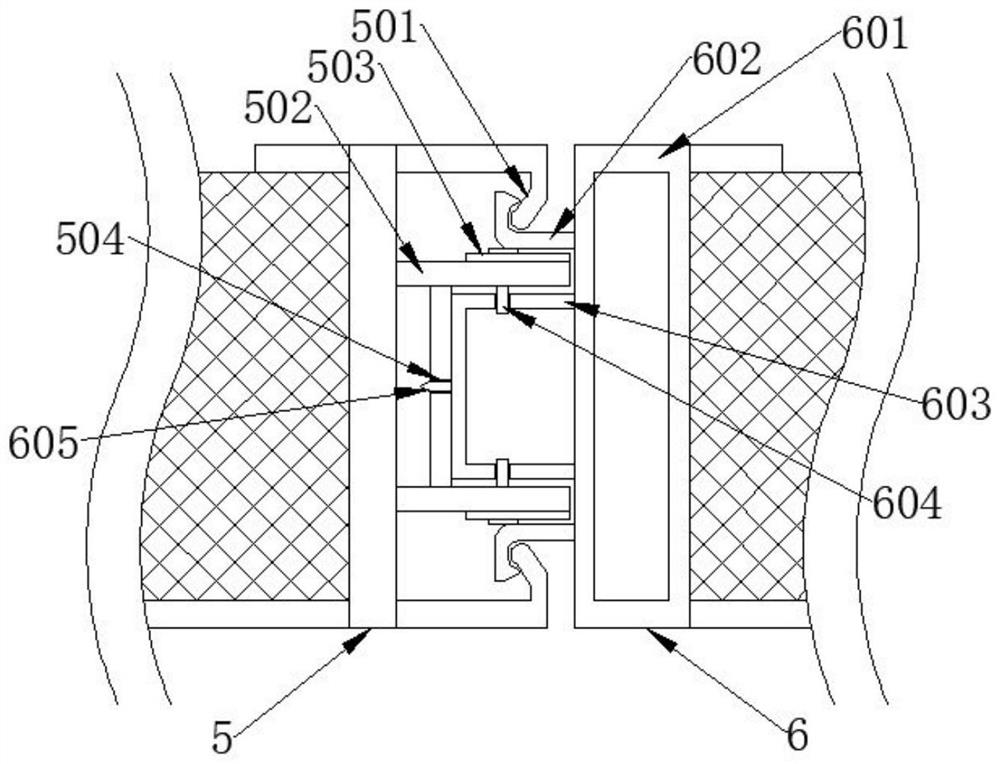

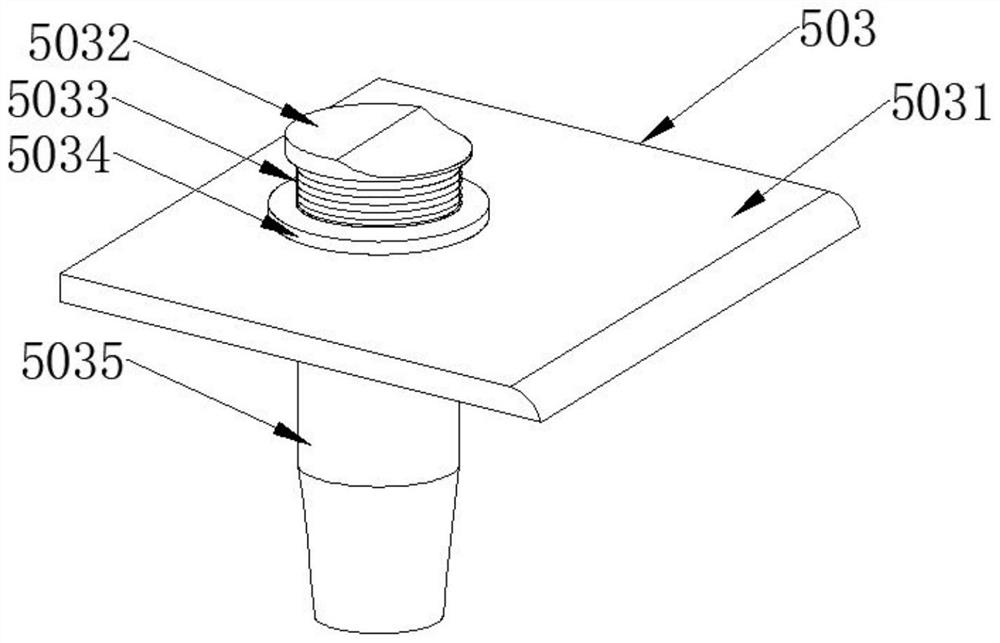

[0028] Such as Figure 1-5 As shown, the present invention provides a spliced photovoltaic module, including a sliding bar 1, a vertical bar 2, a horizontal bar 3 and a solar panel 4, the two ends of the sliding bar 1 are equipped with a vertical bar 2, and the vertical bar 2 and the sliding The rod 1 is detachably connected, and the vertical rod 2 includes an overlapping rod 5 and an inlaid rod 6. One end of the overlapping rod 5 is equipped with a card slot 501, and the card slot 501 is located at the top and bottom ends. The inner side of the draw-in groove 501 is provided with a half-open buckle 502, the top and bottom of the half-open buckle 502 are equipped with a spring telescopic rod 503, and the inner middle part of the half-open buckle 502 is provided with a hole groove 504, so The other end of the mosaic rod 6 is equipped with a protruding block 601, the top and bottom of one side surface of the protruding block 601 are all equipped with an inlaid buckle 602, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com