Edge cutting mechanism in ecological board processing

An ecological board and trimming technology, which is applied to wood processing equipment, special forming/shaping machines, manufacturing tools, etc., can solve the problems of not cleaning in place, low production efficiency, and high production costs of enterprises, so as to avoid damage and simple design , easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

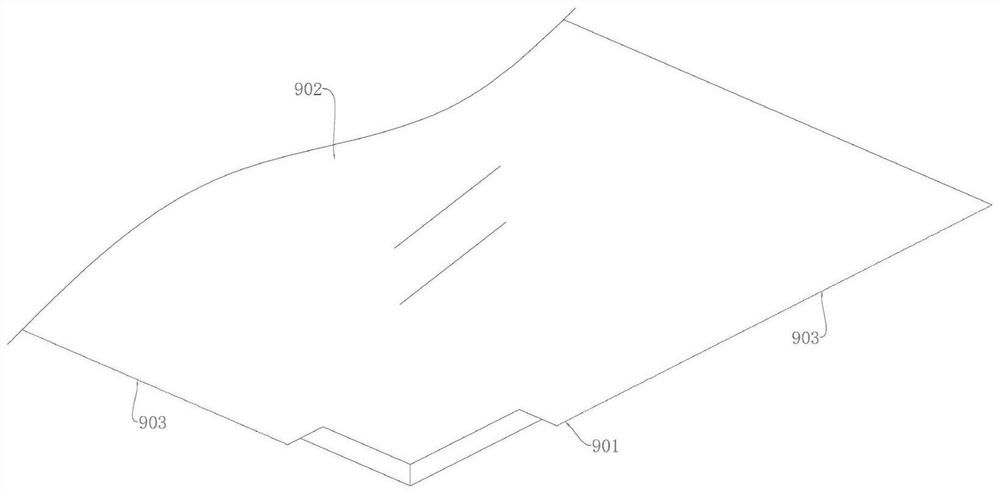

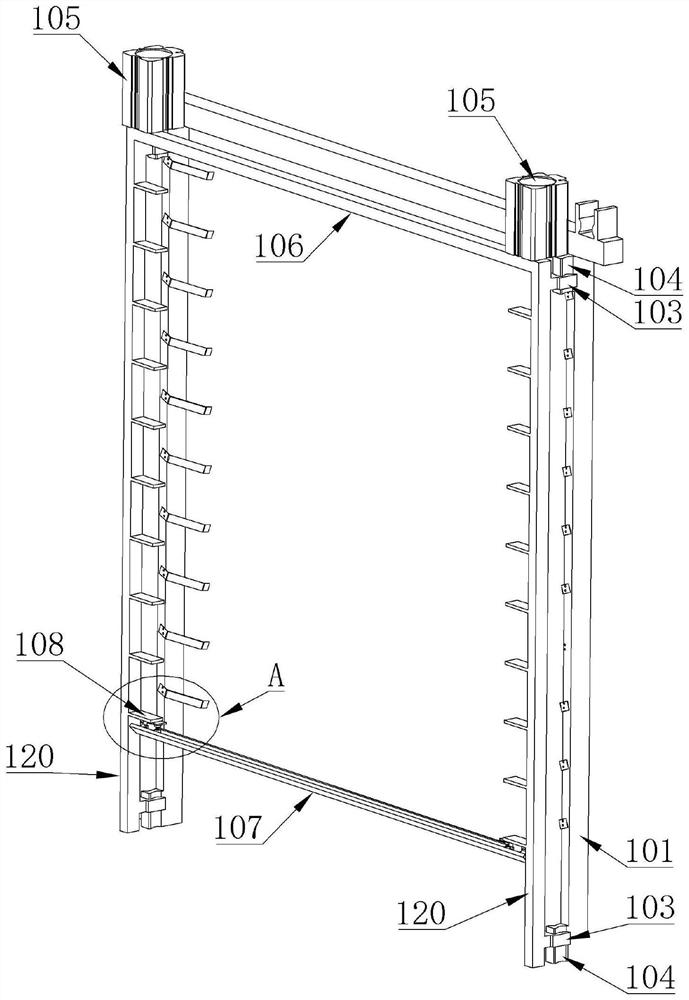

[0022] Embodiment 1: A trimming mechanism in ecological plate processing, see Figure 1 to Figure 8 .

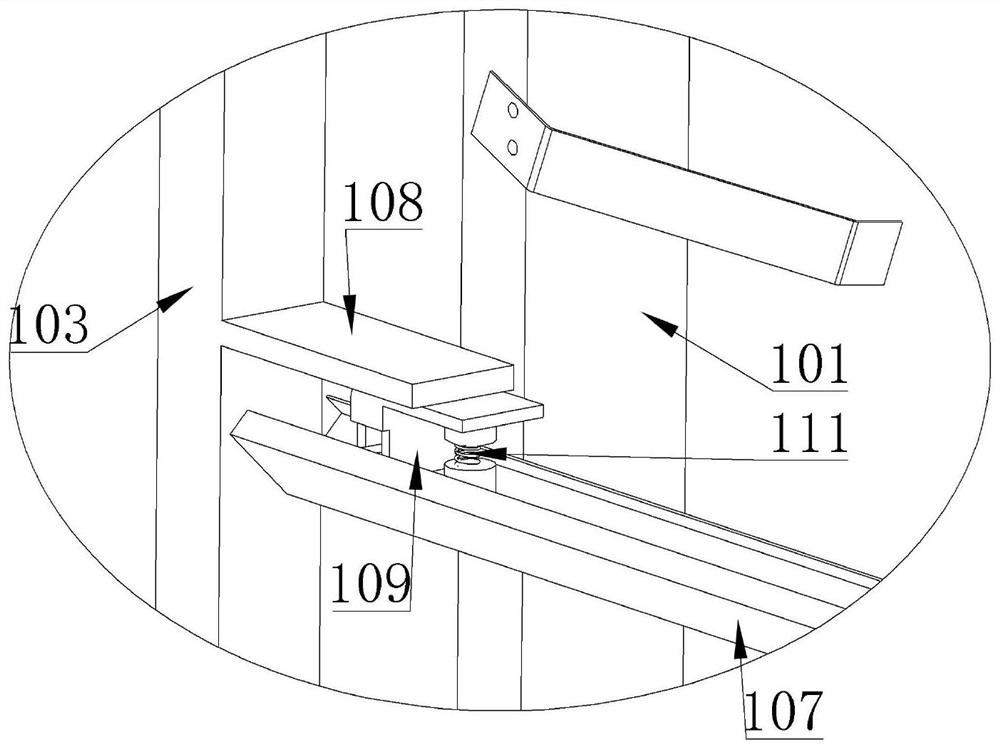

[0023] Including the gantry frame 101, the bottom of the gantry frame 101 is provided with a trimming plate 107 that can move up and down. Swing in both directions.

[0024] Further speaking, the columns on both sides of the gantry frame 101 are respectively provided with slide rails 104, and also includes a mobile frame 120 with an integral structure and a gantry-shaped structure, and the side bars on both sides of the mobile frame 120 pass through the sliders 103 respectively. The sliding buckle is on the slide rail 104 and can move up and down. In this design, the two ends of the trimming board 107 are respectively connected with two side bars on the moving frame 120 .

[0025] Further, the top of the gantry frame 101 is provided with a moving cylinder 105, the telescopic shaft of the moving cylinder 105 is connected with the top 106 of the moving frame 120 and drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com