Tempered glass production and forming post-treatment process

A tempered glass and post-processing technology, applied in conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problems of collision, uneven force, broken tempered glass, etc., to prevent shaking, prevent collision or scratch, Avoid shattering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

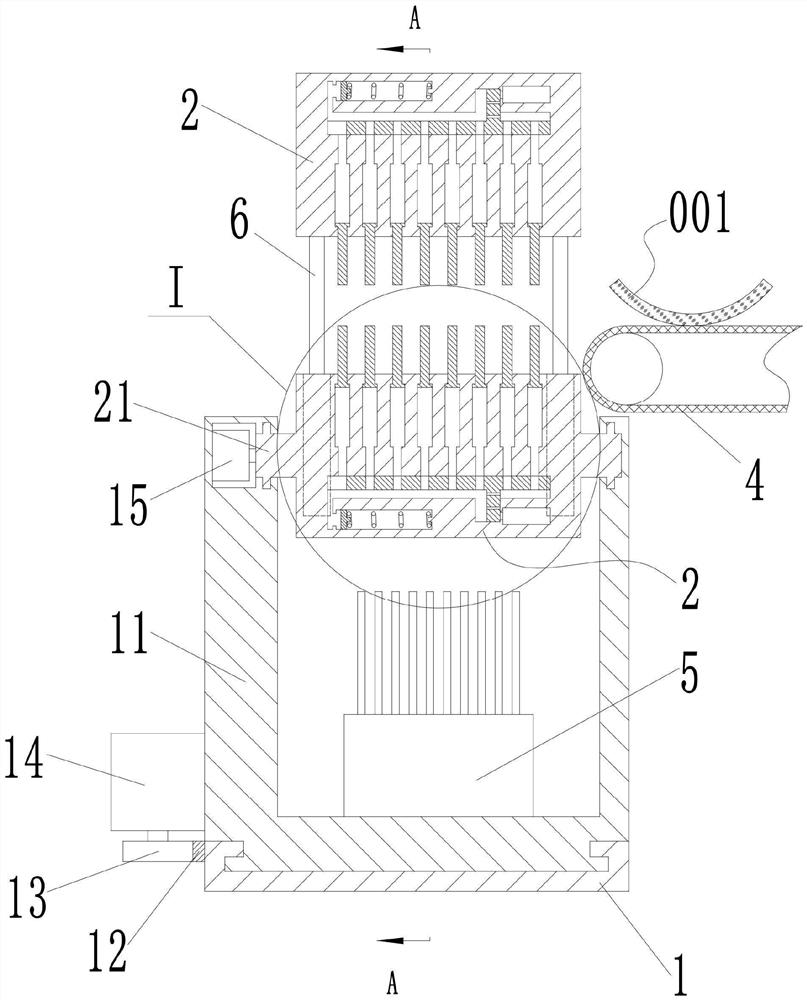

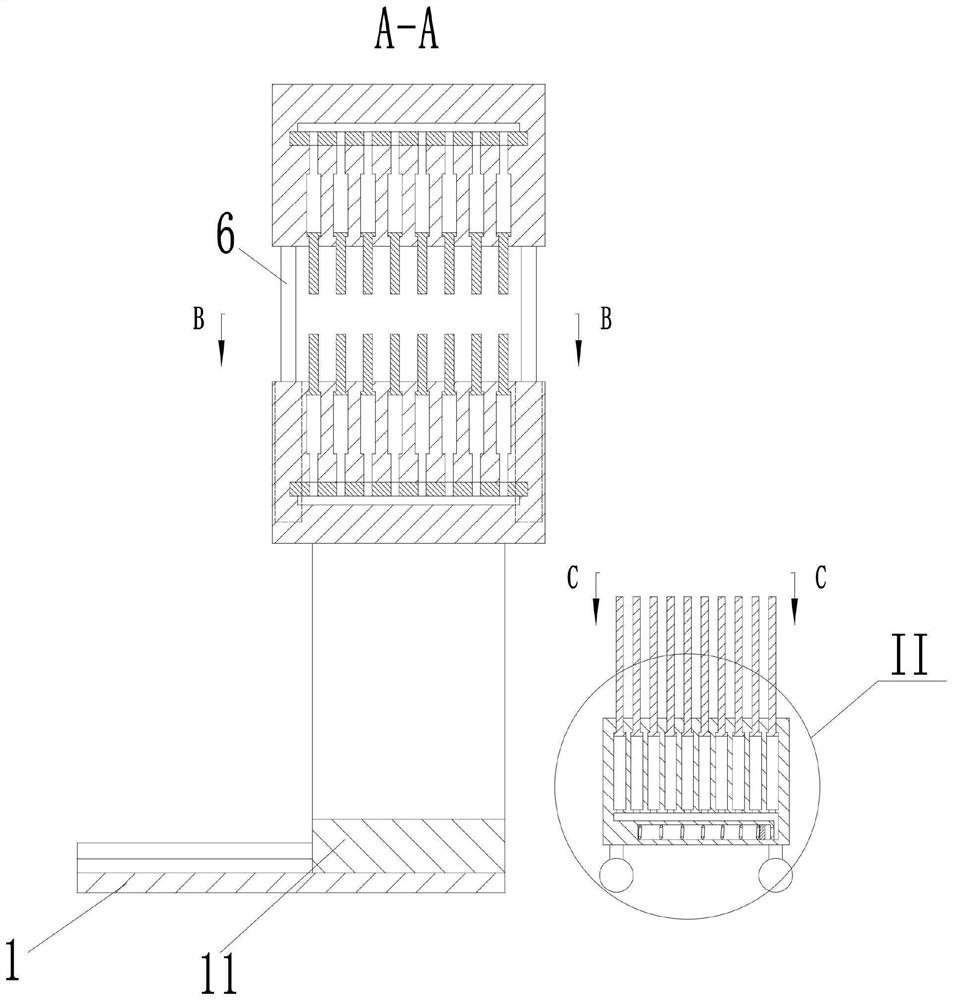

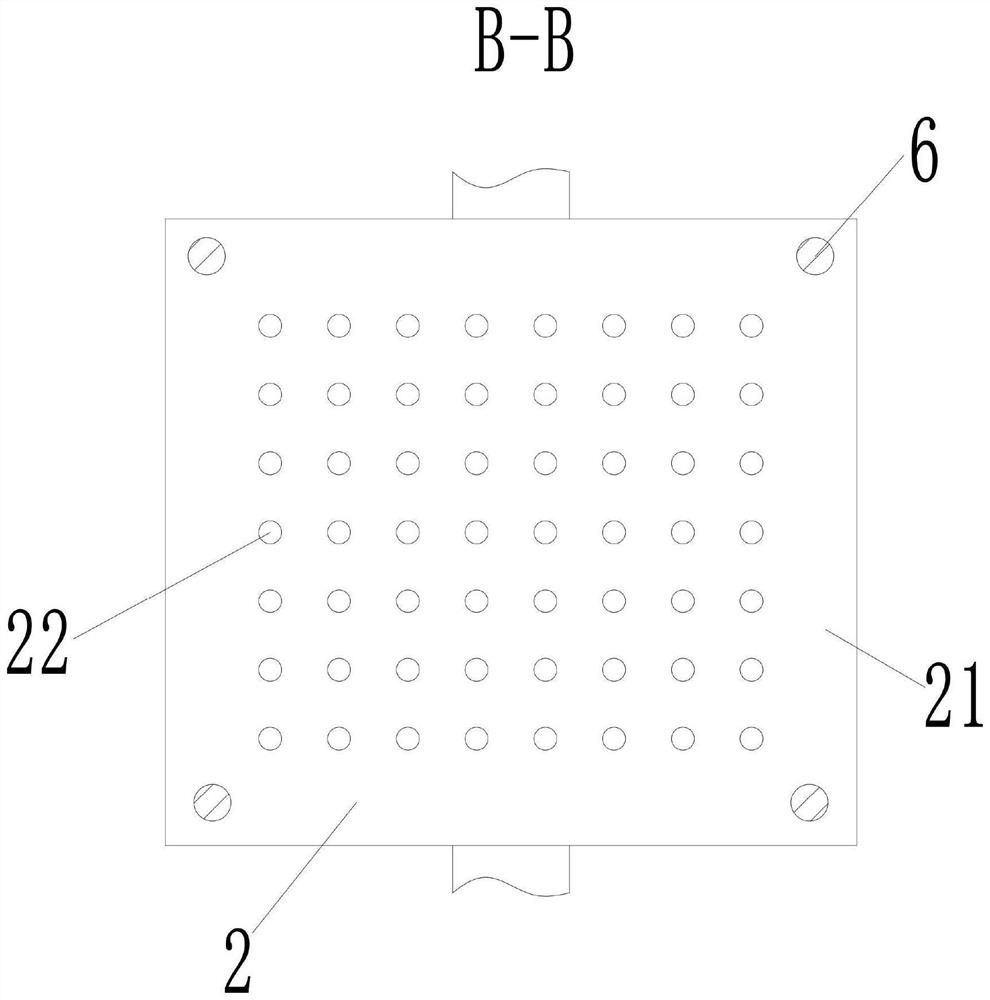

[0033] see Figure 1-8 As shown, a post-processing process for tempered glass production and molding, the post-processing process for tempered glass production and molding uses placement equipment, and the placement equipment includes a holding component and an overturning component; the overturning component includes a bottom plate 1, and the bottom plate 1 A U-shaped frame 11 is slidably connected on the top, and the upper opening of the U-shaped frame 11 is rotatably connected with a clamping assembly. The side of the U-shaped frame 11 is fixedly provided with a second motor 14, and the output of the second motor 14 A gear 13 is fixed on the shaft, and the side of the bottom plate 1 is fixed on the rack 12 meshing with the gear 13; the flipping assembly is used to clamp and fix the tempered glass 001 conveyed by the conveyor belt and flip it to the placed state and send it into the In the assembly; the tempered glass 001 production molding post-processing process includes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com