A kind of cu-sn-p copper alloy material with high tin content and preparation method thereof

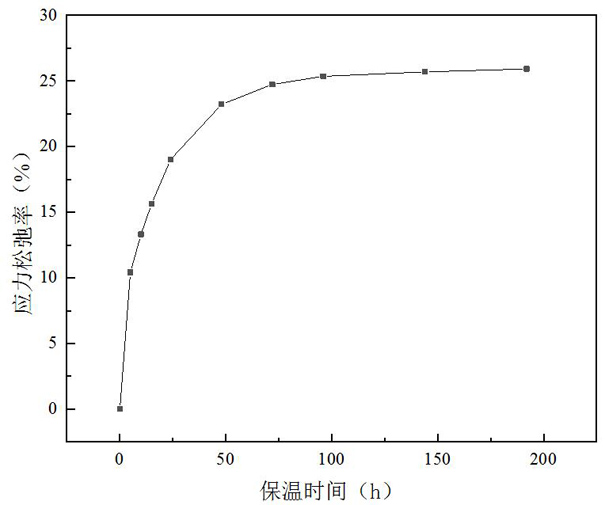

A cu-sn-p, copper alloy technology, applied in the field of copper alloy materials, can solve the problems such as deviation of ingot center composition and set composition, large temperature difference between solidus and liquidus, prone to surface cracks, etc. The effect of reducing residual stress, improving mechanical properties of alloys and improving stress relaxation resistance

Active Publication Date: 2022-06-03

FUZHOU UNIV +1

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

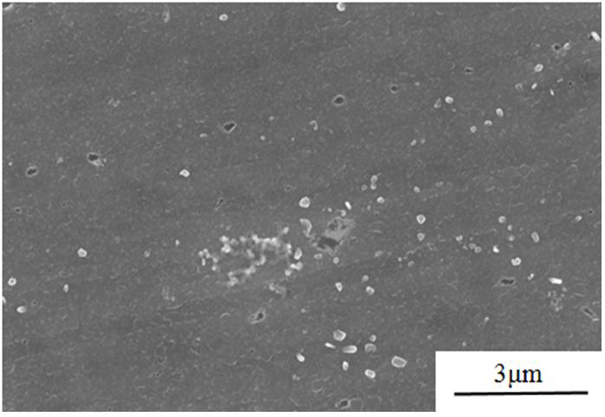

Although the increase of tin content is helpful to improve the mechanical properties and corrosion resistance of tin phosphor bronze, for Cu-Sn-P alloy, due to the large temperature difference between solidus line and liquidus line, during the casting process, the casting slab The temperature gradient is large and the cooling rate is fast, which leads to defects such as dendrite segregation, looseness, and inclusions during solidification, and the as-cast structure is coarse dendrites, which is not conducive to subsequent processing and seriously affects the quality of the strip.

In addition, due to its wide crystallization temperature range, the Sn-rich solution existing between the columnar crystals in the later stage of crystallization will flow back to the surface of the ingot along the gaps between the columnar crystals, forming an anti-segregation layer, which not only leads to loose surface structure, but is also easy to process. Surface cracks appear, and cause a large deviation between the central composition of the ingot and the set composition. The anti-segregation layer must be removed by milling, which will prolong the production cycle and cause waste of raw materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

[0070] The mass percentage of the alloy composition is: 11.50wt% of Sn, 0.45wt% of P, 0.30wt% of Sc, 0.15wt% of

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

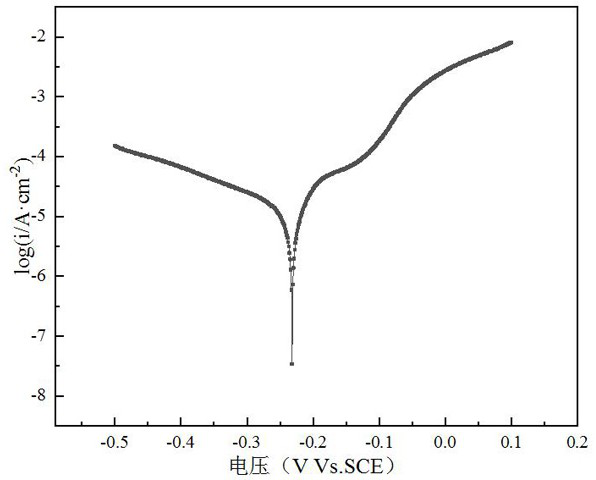

The invention discloses a Cu-Sn-P copper alloy material with high tin content and a preparation method thereof. The copper alloy material is composed of Cu and 10.50-12.50wt% of Sn, 0.30-0.50wt% of P, 0.10-0.35wt% of Sc, 0.05-0.20wt% of Zr, 0.10-0.20wt% of Ni, 0.05-0.10 wt% Zn composition. The preparation method includes alloy melting and casting, pre-rolling at room temperature, homogenization treatment, solid solution treatment, room temperature rolling, intermediate annealing, tension annealing and the like. The composition of the copper alloy material obtained in the present invention does not contain toxic elements, and no toxic substances are produced during the preparation process, which is less harmful to the human body and the environment. The prepared copper alloy material has good strength, stress relaxation resistance, corrosion resistance, etc. Performance, can be applied to the manufacture of various high-performance electronic components, instruments and meters.

Description

A kind of Cu-Sn-P copper alloy material with high tin content and preparation method thereof technical field The invention belongs to copper alloy material technical field, be specifically related to a kind of Cu-Sn-P copper alloy material of high tin content and its preparation method. Background technique Tin phosphor bronze has good elasticity, anti-magnetic properties, good machinability and weldability, and is often used in the manufacture of spring joints. Contact pieces, wear-resistant parts and anti-magnetic components and other components are widely used in electric power, electronics, automobiles, communications and other related fields. Due to the development of components used in industries such as electronics, communications and automobiles toward miniaturization and thinning, tin-phosphorus The stress relaxation resistance of bronze puts forward higher requirements. And with the continuous advancement of electrification and informatization, tin phospho...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C9/02C22F1/08C22F1/02C22C1/03

CPCC22C9/02C22F1/08C22F1/02C22F1/002C22C1/03

Inventor 王晨罗诚盛林晟周建辉张云昊谭文龙洪都

Owner FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com