Standardized complete equipment for mechanical connection of reinforcing steel bars

A technology of mechanical connection and complete set of devices, which is applied in the direction of construction, building reinforcements, building components, etc., can solve the problems of short steel bar connection length, small space for steel bar joints, and heavy welding workload, etc., to overcome the problem of connecting steel bars Short or other defects, good connection effect, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

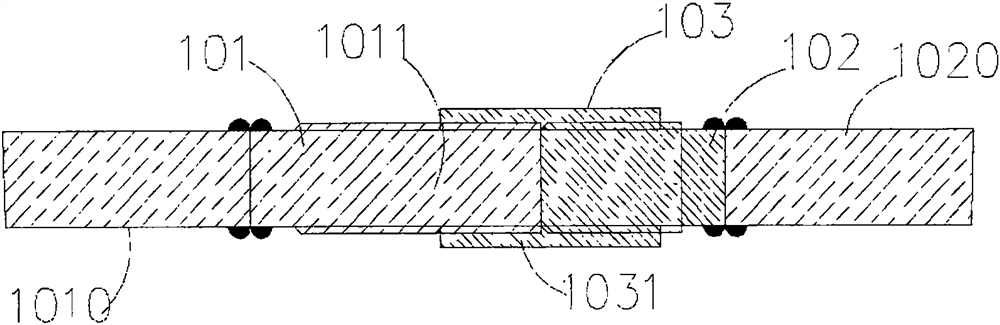

[0053] Such as figure 1 , figure 2 As shown, a complete set of standardization equipment 100 for mechanically connecting steel bars when the steel bars to be connected is difficult to rotate freely. A first component 101 and a second component 102 at the end; and a third component 103 connecting the first component and the second component, the first component 101 and the second component 102 are mechanically connected to the end of the third component 103 respectively . The first assembly 101 includes a long screw 1011; the second assembly 102 includes a screw 1021, and the third assembly 103 includes an outer sleeve 1031, and the outer sleeve 1031 is connected to the first assembly 101 through a built-in screw thread. The screw thread of the long screw rod 1011 and the screw thread of the screw rod 1021 of the second component 102 are fixedly connected.

[0054] The complete set of standardization device 100 for the mechanical connection of steel bars in this embodiment ...

Embodiment 2

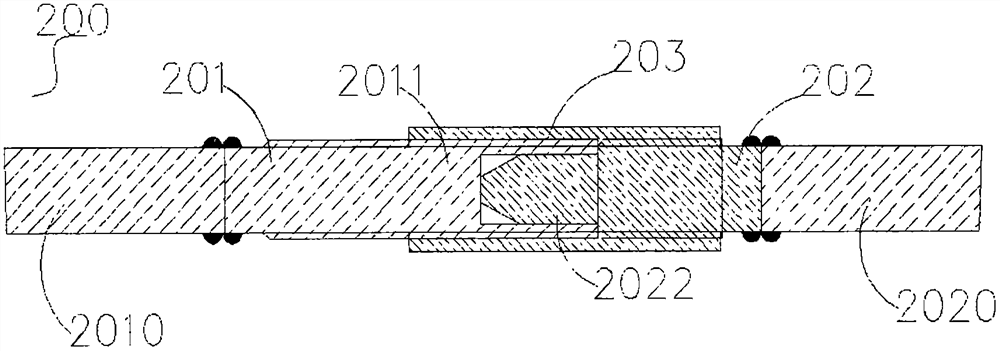

[0056] Such as image 3 , Figure 4 As shown, the standardized complete set of equipment 200 for mechanically connecting steel bars is respectively connected to the ends of steel bars, which includes a first assembly 201 and a second assembly 202 respectively connected to the ends of external steel bars; and connecting the first assembly 201 and the third assembly 203 of the second assembly 202, the first assembly 201 includes a long screw 2011 and a reserved recess 2012 formed by inwardly recessing the end of the long screw 2011; the second assembly 202 includes a screw 2021 and The protruding guide part 2022 located at the end of the screw rod 2021, the reserved recess 2012 is nestedly connected with the protruding guide part 2022; the third component 203 is an outer sleeve 2031, which is threaded with the first component 201 The long screw 2011 is connected with the screw 2021 of the second component 202 .

[0057] In practical application, the complete set of standardiza...

Embodiment 3

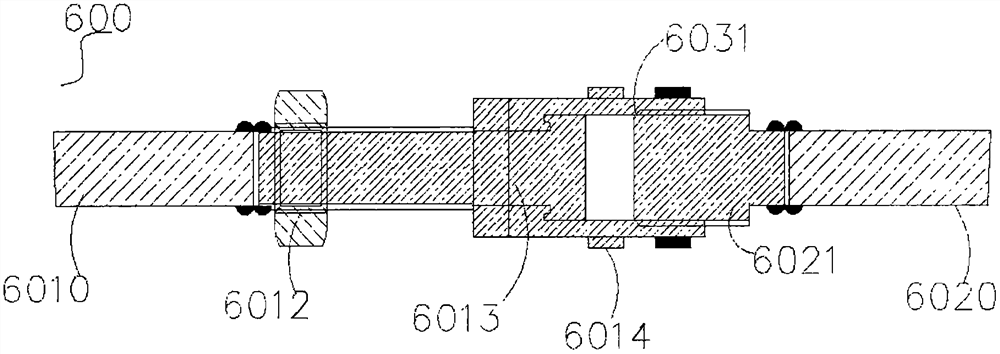

[0059] Such as Figure 5 , Image 6 As shown, the standardized complete set of equipment 300 for mechanically connecting steel bars is respectively connected to the ends of steel bars, which includes a first assembly 301 and a second assembly 302 respectively connected to the ends of external steel bars; and connecting the first assembly 301 and the third component 303 of the second component 302, the first component 301 includes a single-sided internal thread sleeve 3011 formed by inwardly recessing the end, and the second component 302 includes an end corresponding to the first component A single-sided internally threaded sleeve 3021 formed by inward depression; the third component 303 includes a connecting screw 3031; Set the built-in thread for threaded connection.

[0060] The complete set of standardization device 300 for steel bar mechanical connection in this embodiment is applicable to the non-movable and non-rotatable connecting steel bar 3010, and the non-movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com