Differential pressure driving type four-way valve and refrigerating system

A differential pressure drive, four-way valve technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of reduced service life and reliability, waste of electric energy of solenoid valves, etc., to avoid waste, save electric energy, and simplify Effects of Design and Control Sophistication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

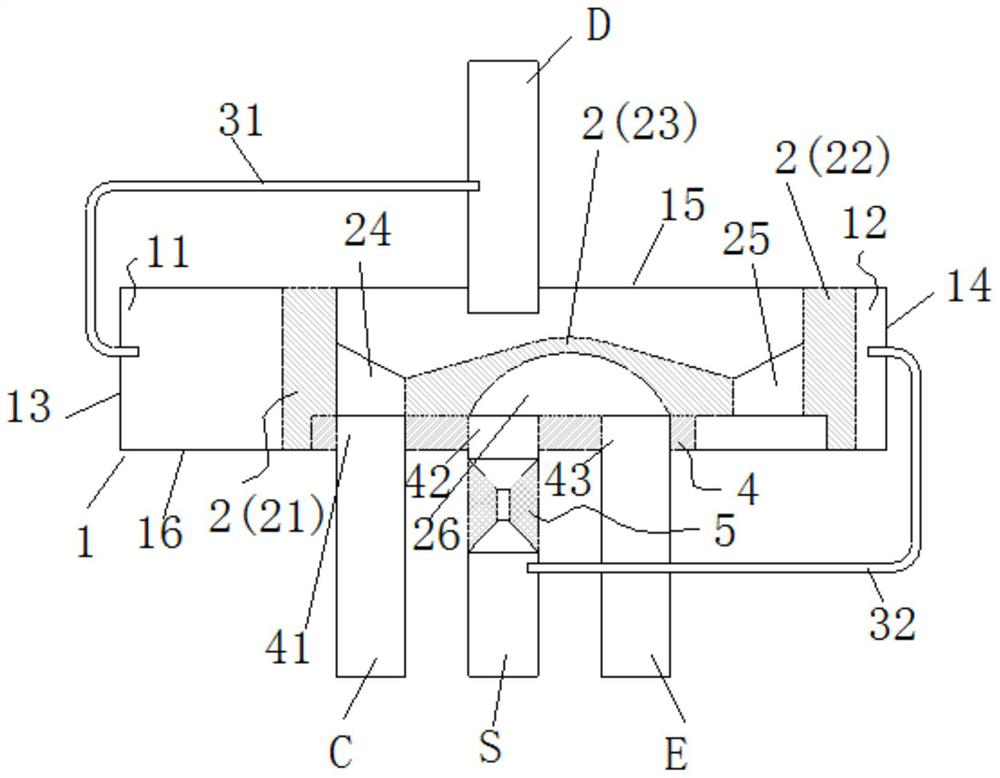

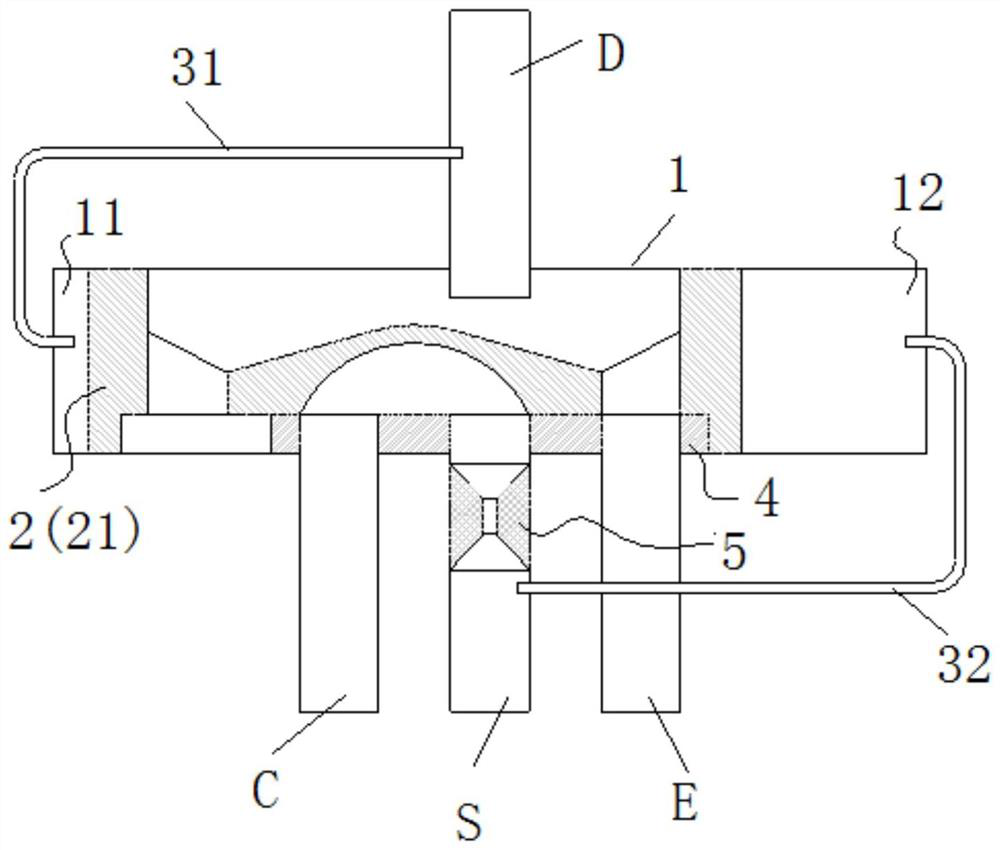

[0033] Example 1, such as Figure 1-2 As shown, the present invention provides a differential pressure driven four-way valve, which includes:

[0034]Valve body 1, sliding body 2, D pipe D, C pipe C, S pipe S, E pipe E, first communicating pipe 31 and second communicating pipe 32, the sliding body 2 is arranged in the valve body 1 and Can slide in the valve body 1, the D pipe D, the C pipe C, the S pipe S and the E pipe E communicate with the inside of the valve body 1 respectively, and the valve body 1 includes The piston chamber A11 on one side of the reciprocating movement of the slider 2 and the piston chamber B12 on the other side of the reciprocating movement, one end of the first communication pipe 31 communicates with the D pipe D, and the other end communicates with the piston chamber A11 communicates to introduce pressure from the D pipe D into the piston chamber A11, one end of the second communication pipe 32 communicates with the S pipe S, and the other end commu...

Embodiment 2

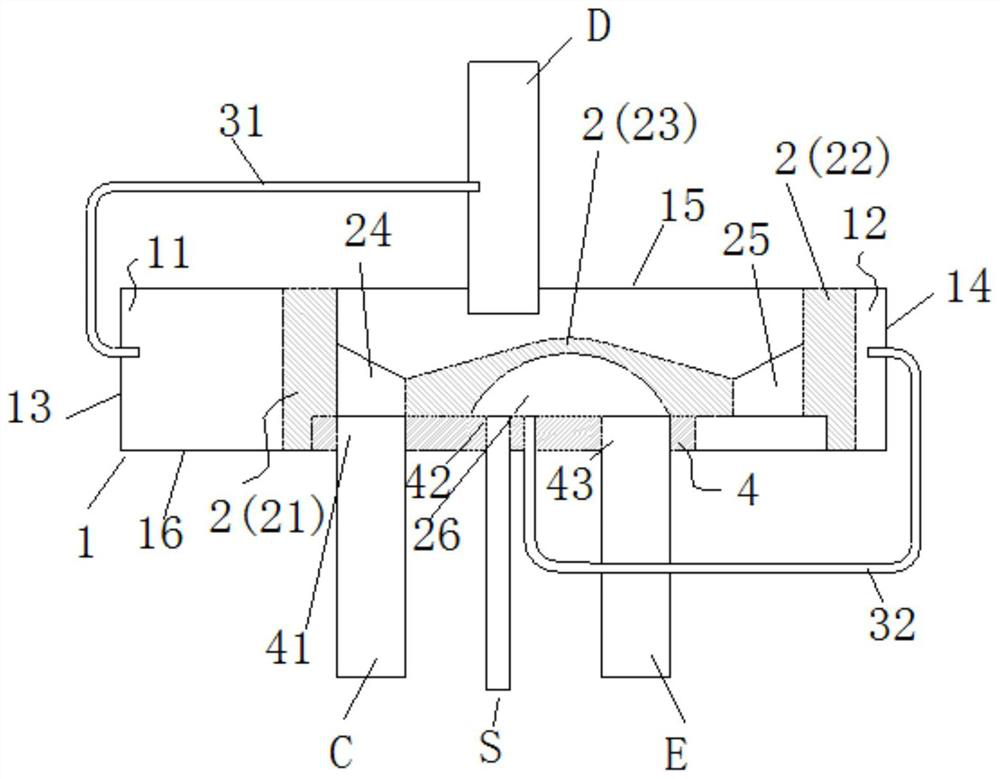

[0056] Example 2, such as Figure 3-4 , in some embodiments, the entire section of the S pipe S is a throttle pipe structure, which is fixedly connected with the valve body 1 . See attached for alternative examples image 3 And attached Figure 4 , with attached figure 1 And attached figure 2 The difference is that the pipe where the S port is located is changed to a throttle tube or a capillary tube. At the same time, the capillary tube B and the S tube are no longer directly connected. The tube port of the capillary tube B is directly connected to the valve body and welded firmly. The process is the same. Other structural design and accessories of four-way valve figure 1 And attached figure 2 same.

[0057] The present invention also provides a refrigeration system (preferably a dual-mode refrigeration system), which includes the differential pressure driven four-way valve described in any one of the preceding items. When working, under one mode, tube D has high pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com