Grounding wire device

A technology of grounding wire and grounding wire clamp, which is applied in the field of electric power, can solve the problems of increasing the danger of high-altitude operations, the safety distance is easily violated, and threatening the safety of staff, so as to reduce the number of operations on poles and improve line maintenance and troubleshooting. Efficiency and the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

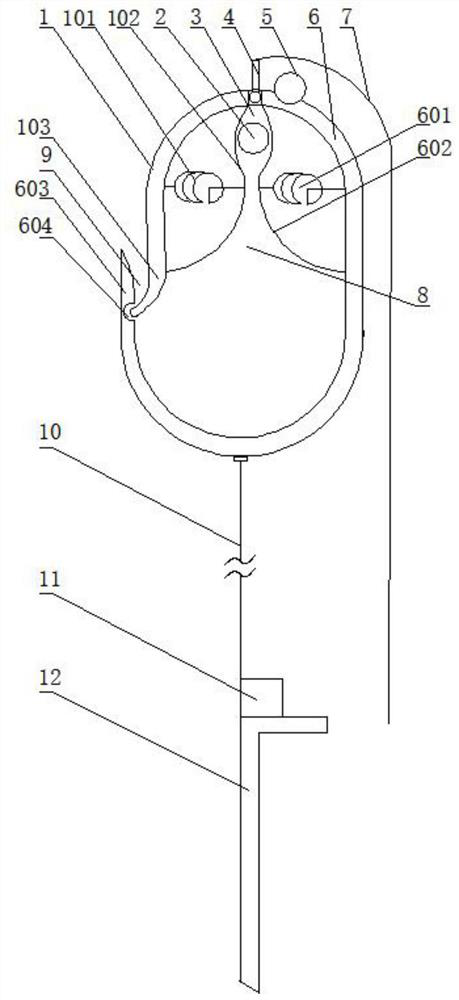

[0020] A grounding wire device, comprising a grounding wire clamp, a grounding down conductor 10, a grounding electrode 12 and an electroscope 11, wherein the grounding wire clamp is connected to one end of the grounding down conductor 10, and the other end of the grounding down conductor 10 is connected to the grounding electrode 12. An electroscope 11 is installed on the top of the ground electrode 12 .

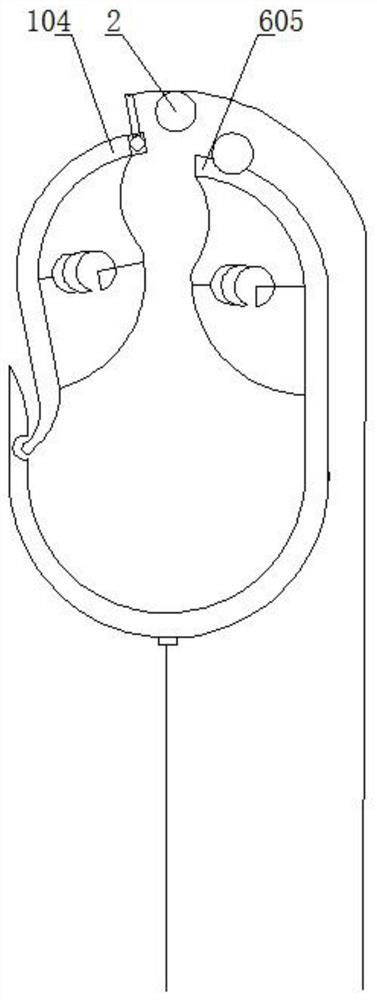

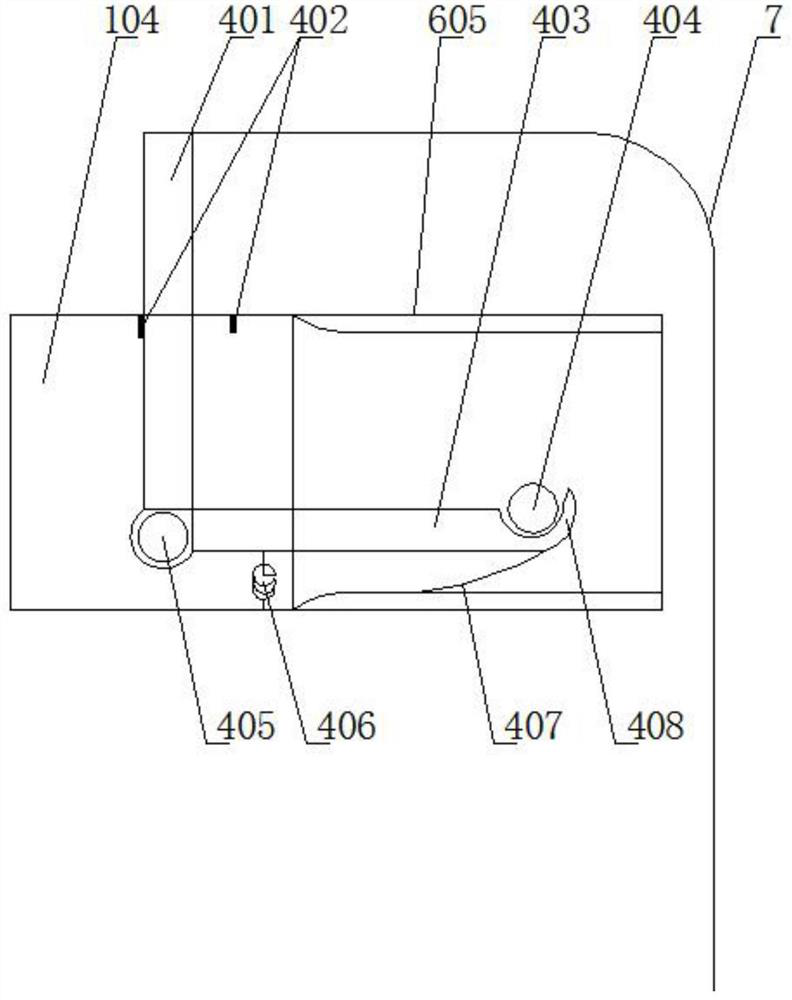

[0021] The ground wire clamp includes a clamp body, a hook 5 and a release mechanism 4 .

[0022] The clip body includes two parts: a fixed half clip 6 and a movable half clip 1. The first end 605 of the fixed half clip is fixed to the hook 5, and the second end 603 of the fixed half clip is connected to the first end 603 of the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com