High-voltage pouring bus duct plugging unit

A bus duct and high-voltage technology, applied in the field of bus duct, can solve the problems of displacement and bumping of the plug unit, reduce the practicability of the plug unit, and damage the plug unit and the surrounding structure due to moisture, so as to reduce the possibility of moisture damage and reduce the The effect of shifting and bumping phenomenon and improving the moisture-proof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

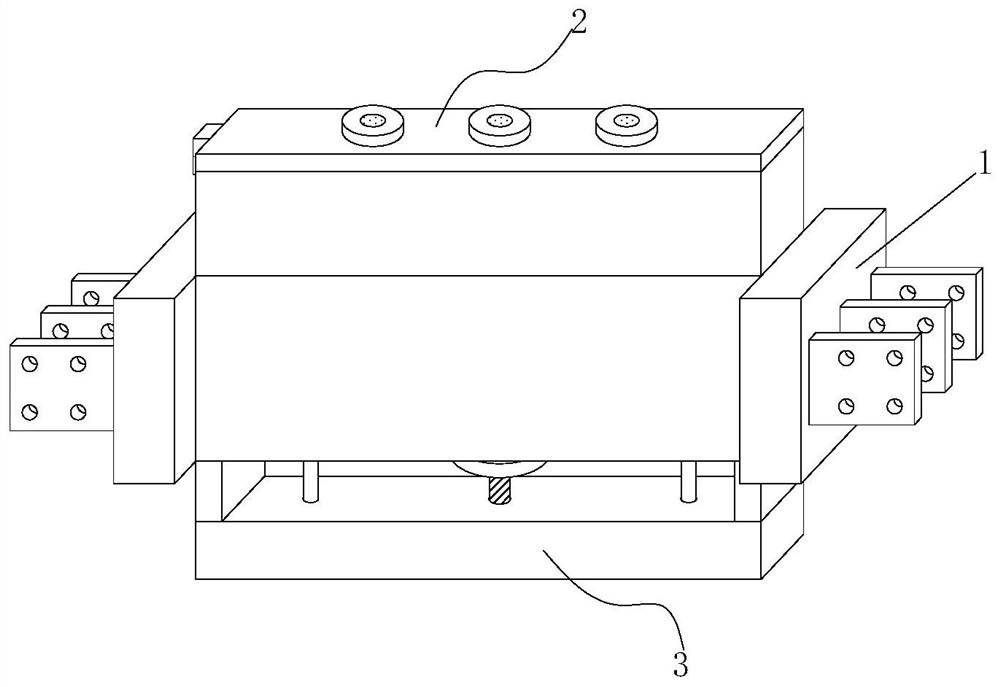

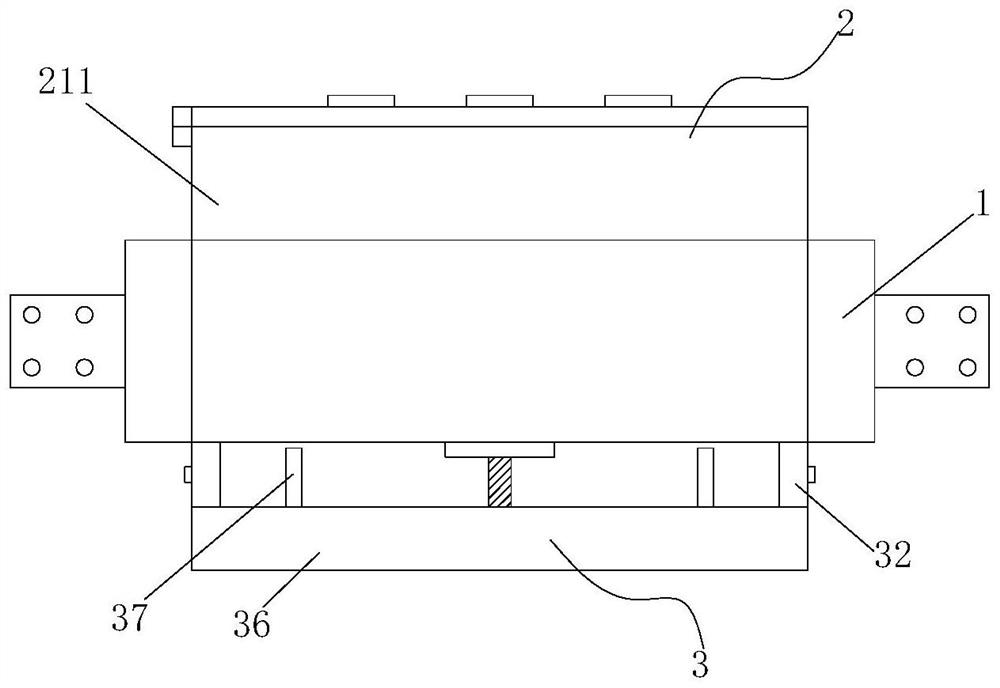

[0025] see Figure 1-4 , the present invention provides the following technical solutions: a high-pressure cast bus duct plug-in unit, including a high-pressure cast bus duct plug-in unit main body 1, and a moisture-proof device 2 is installed above the high-pressure cast bus duct plug-in unit main body 1;

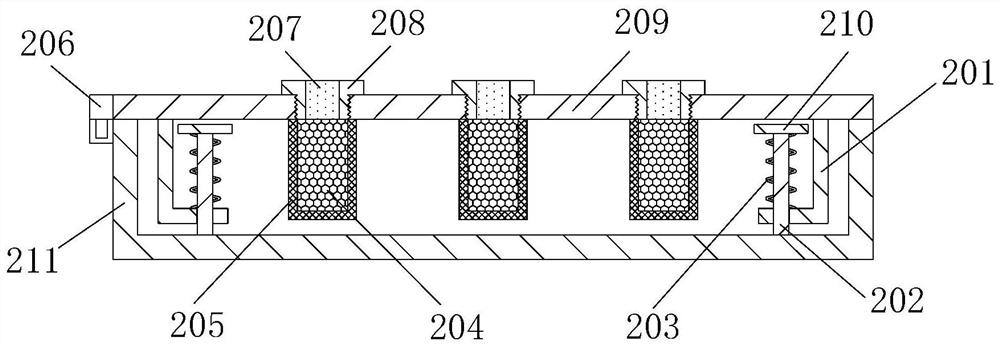

[0026] The moisture-proof device 2 includes a mobile frame 201, a guide rod 202, a tension spring 203, a silica gel desiccant 204, a net cylinder 205, a buckle 206, a closing plate 209, a limiting plate 210, a fixed box 211, and a high-pressure cast busway plug-in unit A fixed box 211 is installed above the main body 1, and a closed plate 209 is arranged above the fixed box 211. The fixed box 211 and the closed plate 209 are connected by a buckle 206, and the bottom of the closed plate 209 is located inside the fixed box 211. A plurality of net tubes 205 are installed, the inside of the net tube 205 is filled with silica gel desiccant 204, the inside of the fixed box 211 a...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that a fixing device 3 is provided under the main body 1 of the high-pressure casting bus duct, and the fixing device 3 includes a suction cup 34, a moving plate 35, a bottom box 36 and a screw rod 38. A bottom box 36 is arranged below the slot plug-in unit main body 1, and a screw rod 38 is installed by threads at the central position of the bottom box 36, and a moving plate 35 is installed on the outer side of the lower end of the screw rod 38 and positioned at the inside of the bottom box 36 through a bearing. A plurality of suction cups 34 are installed below the plate 35,

[0036] By adopting the above technical solution, the plug-in unit can be auxiliary fixed by the suction cup 34 when needed, thereby reducing the possibility of displacement and bumping of the plug-in unit during transportation or installation.

[0037] Specifically, the fixing device 3 also includes a knob 31, and the knob 31 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com