Integrated optimized lifting structure of cookware tray

A lifting structure and material tray technology, which is applied to the structure of cooking utensils, kitchen utensils, household utensils, etc., can solve the problems of unreasonable assembly of components, difficult disassembly and assembly operations, poor stability of the lifting and lowering of the material tray, etc., to simplify the assembly process, The effect of quick disassembly and assembly and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

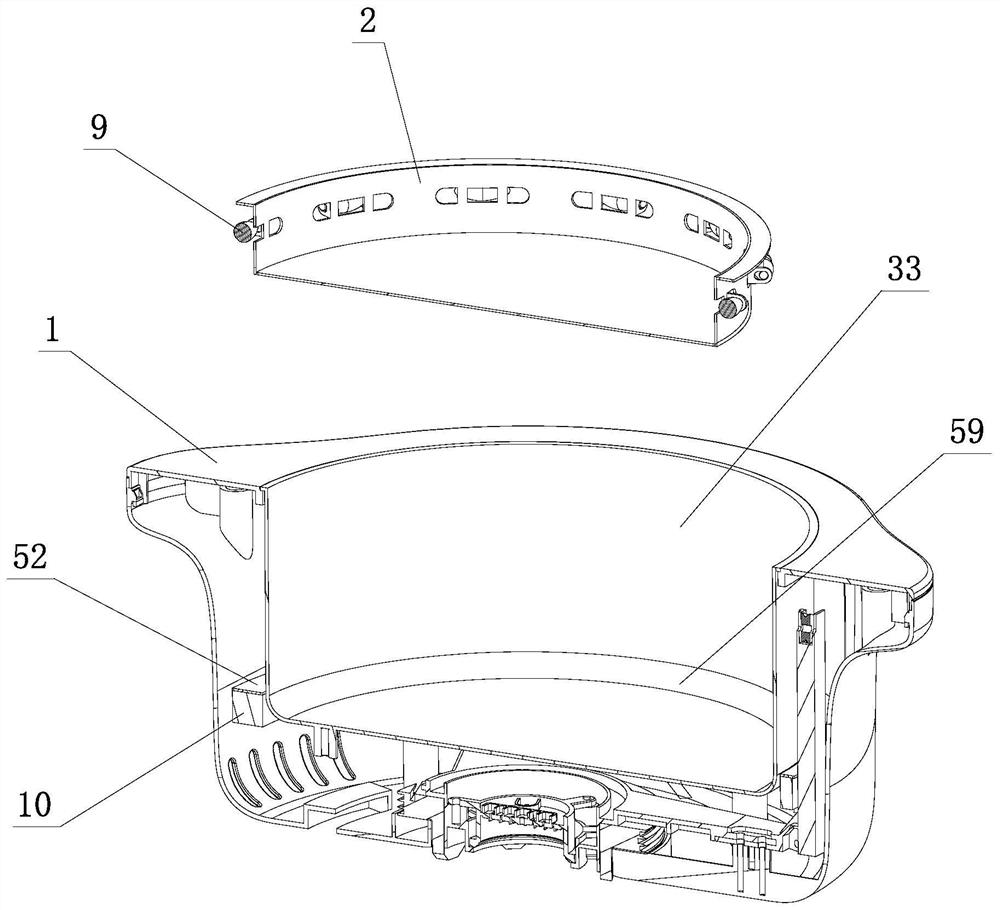

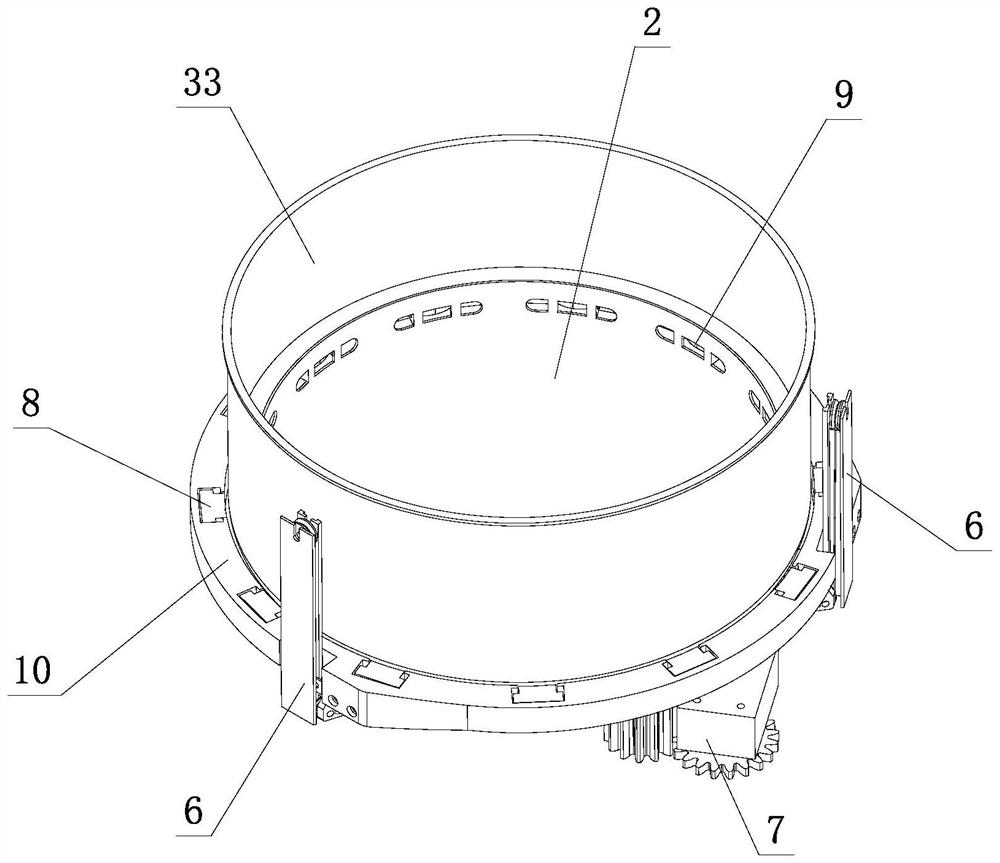

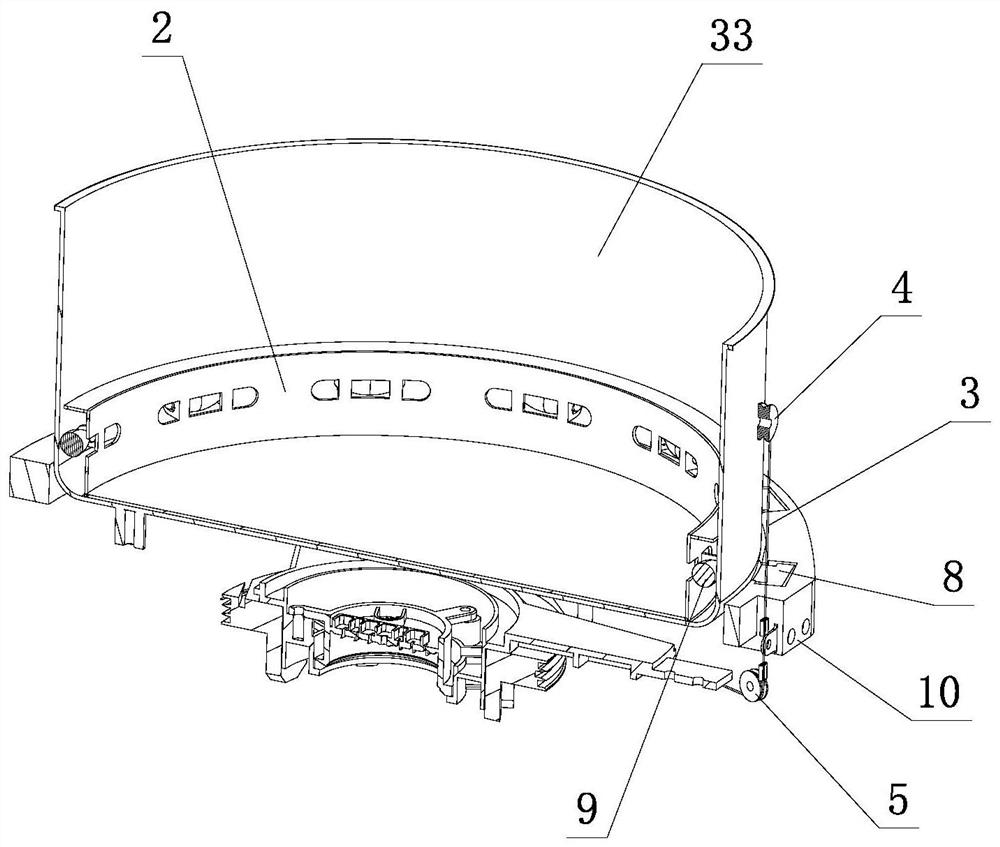

[0044] see Figure 1-Figure 9 , the integrated and optimized lifting structure of the pot material tray includes a pot body 1, an inner container 33 is arranged in the pot body 1, a material tray 2 is arranged in the inner container 33, and a plurality of rolling parts 9 are arranged in an array on the periphery of the material tray 2; The outside of the inner tank 33 is provided with a lifter 10, and on the lifter 10, there are several magnetic bodies 8 that are magnetically matched with the rolling member 9 or the material tray 2; , and when lifting up and down, the magnetic attraction force of the magnetic body 8 drives the material tray 2 up and down in the liner 33.

[0045] Utilizing the magnetic force generated by the magnetic body 8, the lifting member 10 can drive the material tray 2 to move up and down synchronously in the liner 33 when moving up and down, so as to complete the solid-liquid separation in the food.

[0046] The space between the magnetic body 8 and t...

no. 2 example

[0080] see Figure 10-Figure 15 , the integrated and optimized lifting structure of the pot tray is different from the first embodiment in that: there are several holes at the bottom of the tray 2, and several shrapnels 60 and adapters 61 are arranged on the outside; Several shrapnels 60 are elastically arranged on the outside of the tray 2 respectively, several rolling elements 9 are respectively rolled and arranged on the several shrapnels 60, and several adapter pieces 61 are respectively located on the outside of the rolling elements 9 and are respectively positioned on the tray 2 or On several shrapnels 60; said several rolling parts 9 are rolled and arranged on several shrapnels 60 through several adapters 61 respectively, and when the material tray 2 is lifted up and down, the shrapnels 60 can be adaptively elastically moved on the material respectively. Disk 2 outside.

[0081] Utilizing the elastic effect of the shrapnel 60, the rolling member 9 can adapt to the elas...

no. 3 example

[0092] Such as Figure 16 As shown, similar to the second embodiment, the difference is that the outer side of the tray 2 is integrally punched to form a groove 65, the opening 63 is arranged on the groove 65, and the grooves 65 on both sides of the opening 63 are provided with left and right When assembling the crimping part 90, the shrapnel 60 is arranged in the groove 65, and the side parts of the two ends of the shrapnel 60 are provided with assembly holes 91 that cooperate with the left and right crimping parts 90, so that the boss and the assembling hole 91 form a positioning fit, and then The left and right positioning parts 64 are welded at the corresponding positions of the left and right crimping parts 90 to limit the position of the elastic piece 60; the function of the groove 65 is to facilitate the assembly of the elastic piece 60, so that the elastic piece 60 has room for adjustment during assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com