Kitchen garbage pretreatment collecting device

A collection device and kitchen waste technology, applied in grain processing, presses, manufacturing tools, etc., can solve problems such as low efficiency, difficult handling, and odors in storage locations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

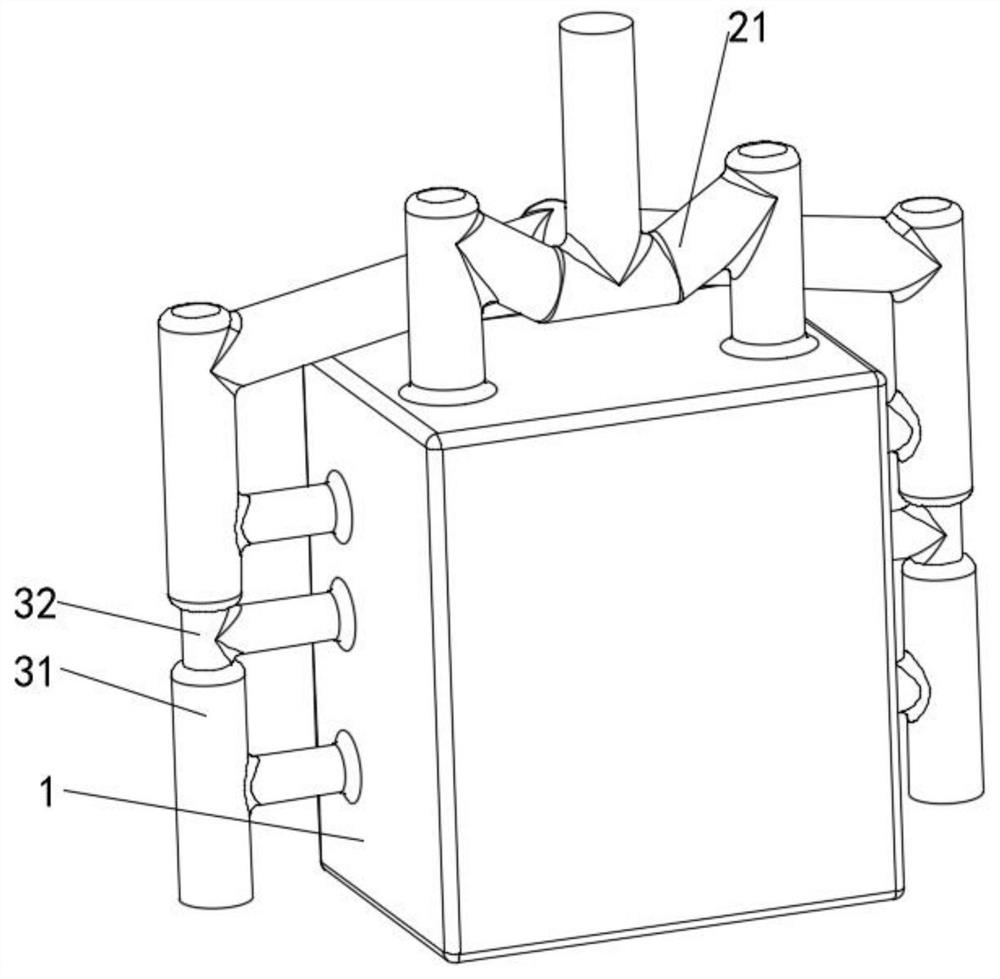

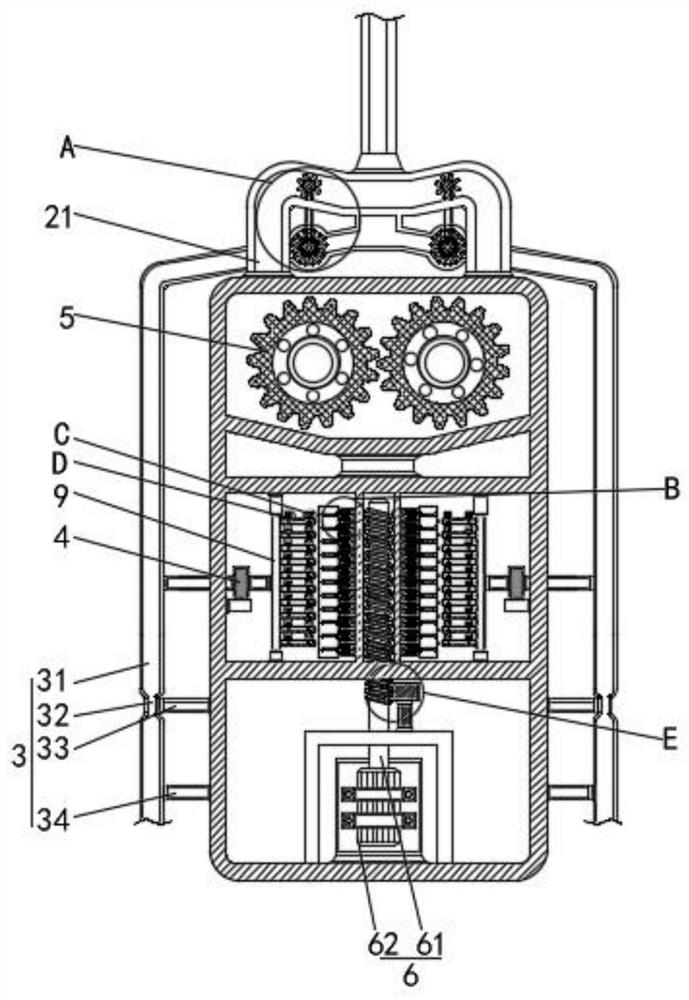

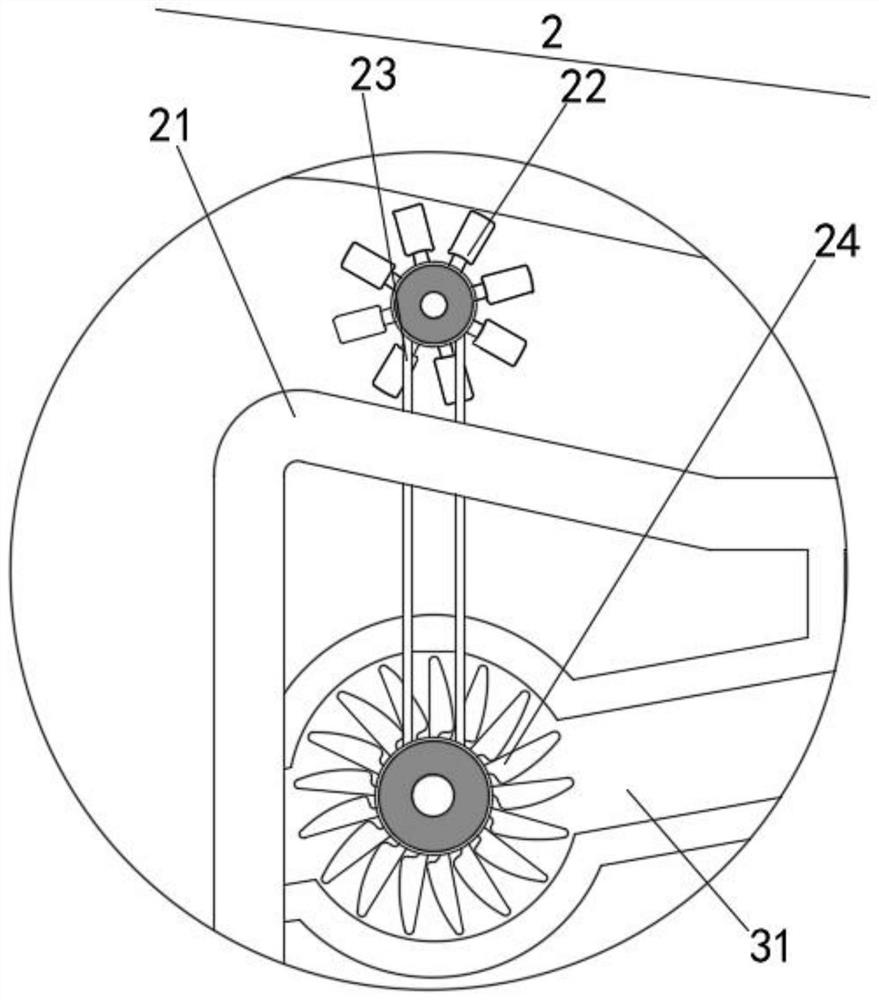

[0029] see Figure 1-7 , a pretreatment collection device for kitchen waste, comprising a box body 1, a feed assembly 2 is fixedly connected to the upper side of the box body 1, a connection assembly 3 is fixedly connected to the rear side of the feed assembly 2, and the inner side of the box body 1 The drive assembly 6 is fixedly connected, and the left and right sides of the drive assembly 6 are provided with a display assembly 7, and the outside of the display assembly 7 is provided with a detection assembly 8. The detection assembly 8 includes a flow channel 81, and the inner side of the flow channel 81 is slidably connected with a floating ball. The right side of the rod 82 and the float rod 82 is fixedly connected with a paddle 83, and the right side of the paddle 83 is slidably connected with a sliding rheostat 84.

[0030] Further, the feed assembly 2 includes a feed pipe 21 fixedly connected to the box body 1, the inner side of the feed pipe 21 is rotatably connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com