Ladle turning device for intermediate frequency furnace

A medium-frequency furnace and cladding technology, which is used in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of lack of moving function and dumping function, troublesome and dangerous, troublesome and dangerous, etc., and achieve efficient transfer and transportation operations. Reliable, continuous scrolling function, avoids the effect of accidental movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

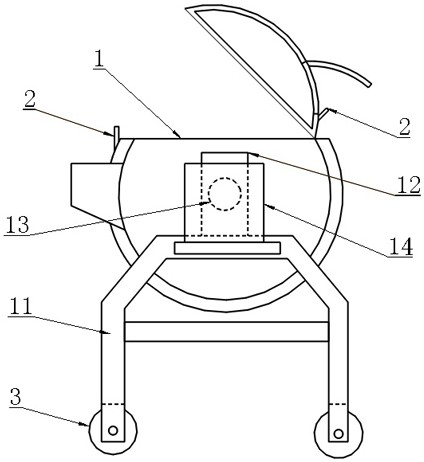

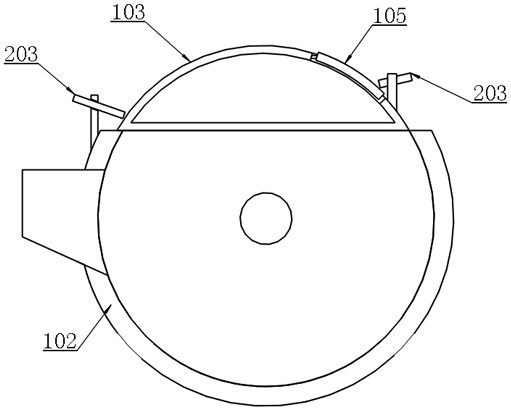

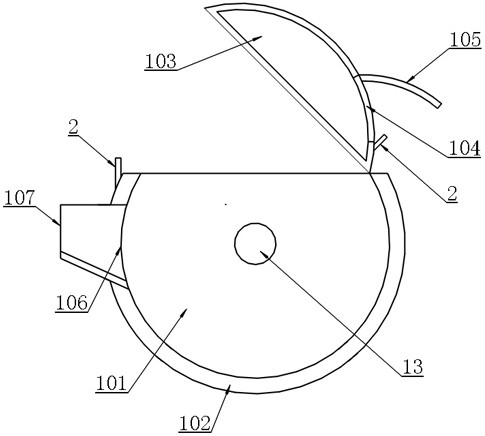

[0028] Example: as attached Figure 1-6 As shown, a subcontracting device for an intermediate frequency furnace includes a fixed frame 11, a fixed orifice plate 12, a package body installation shaft 13, and a rotating drive motor 14, and also includes normal The open enclosure unit 1, the closing clamping column unit 2 arranged on the normally open enclosure unit 1, and the clamping column unit 2 arranged on the fixing frame 11 and taken off by the closing clamping column unit 2 The way of locking and limiting in the rear is used to fix the roller unit 3 of the subcontracting device.

[0029] In this embodiment, since the subcontracting device is used for extremely high-temperature molten metal, the entire device has no electrical or electronic components, which also ensures the reliability of the entire molten metal subcontracting operation, although it may be convenient to use It has been reduced, but the safety has been greatly improved, which is the most critical in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com