Hollow brick with sound insulation and heat insulation functions

A hollow brick and functional technology, applied in building materials, building components, buildings, etc., can solve the problems of lack of sound insulation and heat insulation, unsatisfactory use, waste of raw materials, etc., to achieve heat isolation, ingenious structure setting, and good heat insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

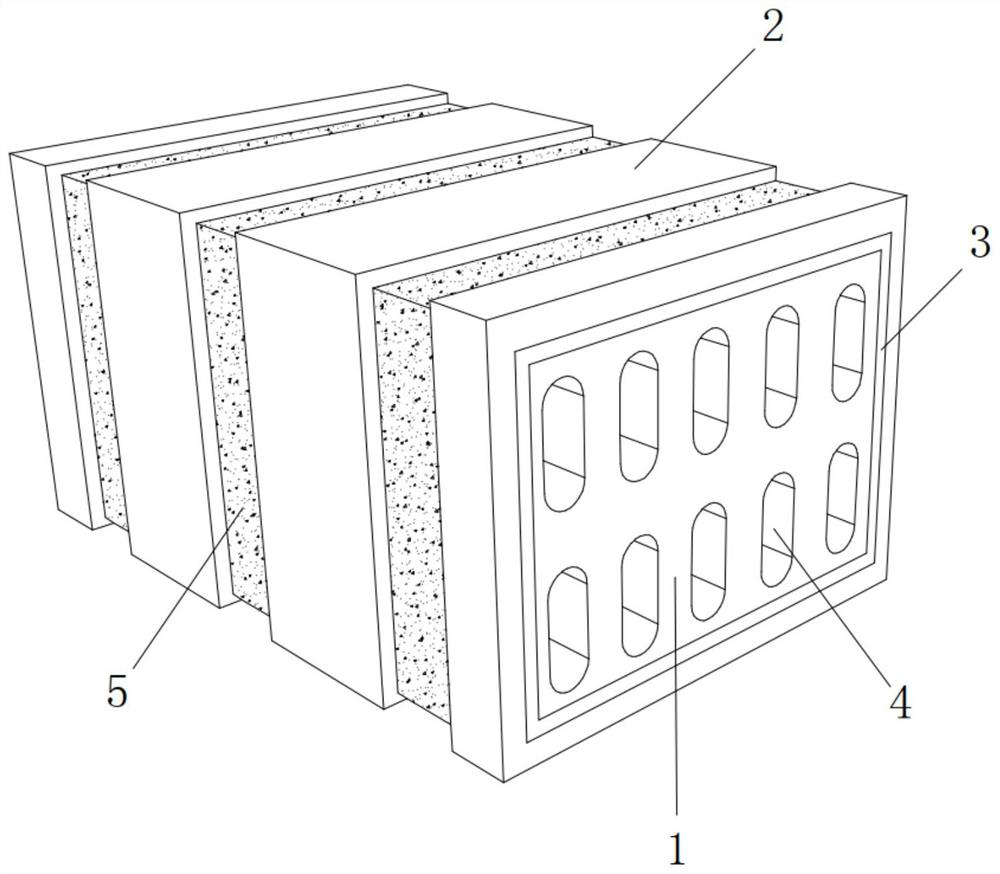

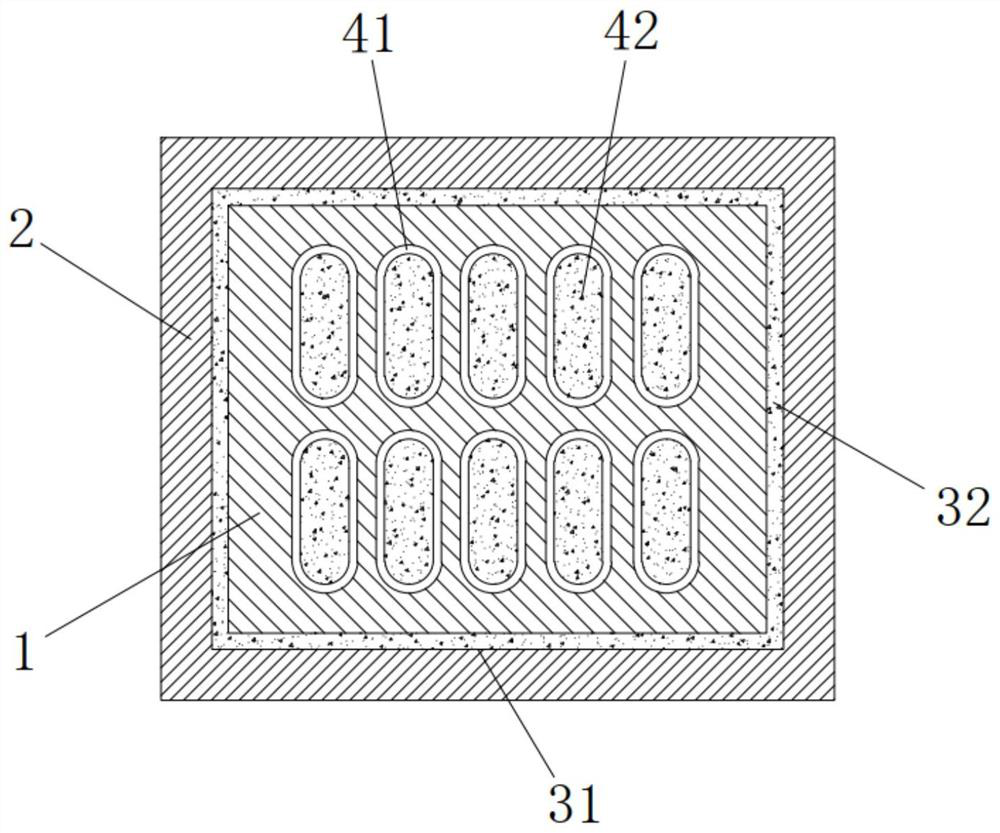

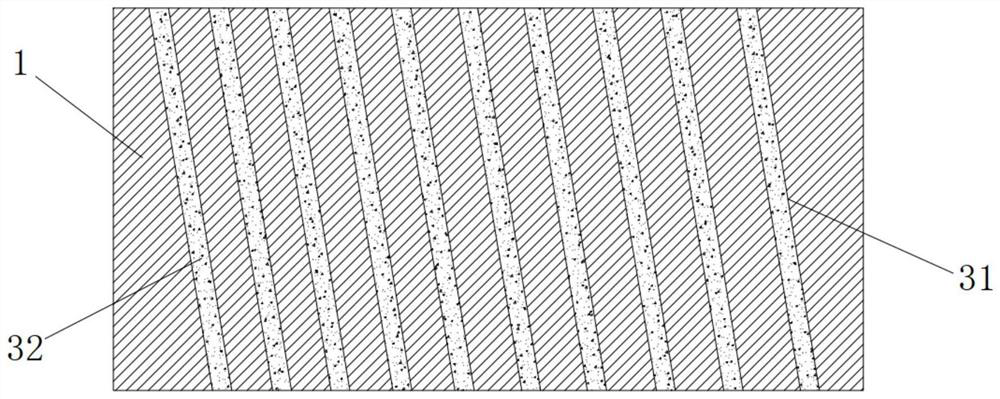

[0026] see Figure 1-3 , a hollow brick with sound and heat insulation functions, comprising an inner brick body 1 and an outer brick body 2, a sound insulation layer 3 is arranged between the inner brick body 1 and the outer brick body 2; Noise reduction groove 31, said noise reduction groove 31 is opened around the inside of said sound insulation layer 3, is convenient to eliminate noise through noise reduction groove 31; The inside of said noise reduction groove 31 is filled with noise reduction foam 32, and said sound reduction foam 32 surrounds setting In the interior of the sound-absorbing groove 31, it is convenient to further eliminate noise through the sound-absorbing foam 32;

[0027] The inner brick body 1 is provided with a hollow hole 4, the cross-section of the hollow hole 4 is a rectangle with upper and lower ends combined with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com