Preparation method of nanowire silver film for packaging and interconnection of large-size power semiconductor integrated circuit

A technology for power semiconductors and integrated circuits, which is applied in the field of preparation of nanowire silver films for packaging and interconnection of large-scale power semiconductor integrated circuits, can solve problems such as process adaptability and insufficient use performance, and achieves low porosity, stable performance, The effect of reducing thermomechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention proposes a method for preparing a nanowire silver film for encapsulating and interconnecting large-scale power semiconductor integrated circuits, comprising the following steps:

[0021] S1: diluting and purifying the silver nanowire mother liquor to obtain a silver nanowire dispersion;

[0022] S2: performing pressure filtration or suction filtration on the silver nanowire dispersion to obtain a wet nanowire silver film;

[0023] S3: drying the wet nanowire silver film to obtain a nanowire silver film.

[0024] Preferably, in step S1, the dilution is specifically:

[0025] The silver nanowire mother liquor is diluted 2 to 20 times with a diluent. The purpose of dilution is to dissolve the organic matter coated on the surface of the silver nanowires into diluents such as water and ethanol to achieve the purpose of purification.

[0026] Preferably, the diluent is ethanol, deionized water or other alcoholic low-boiling organic solvents. The surf...

Embodiment 1

[0039] This embodiment provides a method for preparing a nanowire silver film for encapsulation and interconnection of large-scale power semiconductor integrated circuits, including the following steps:

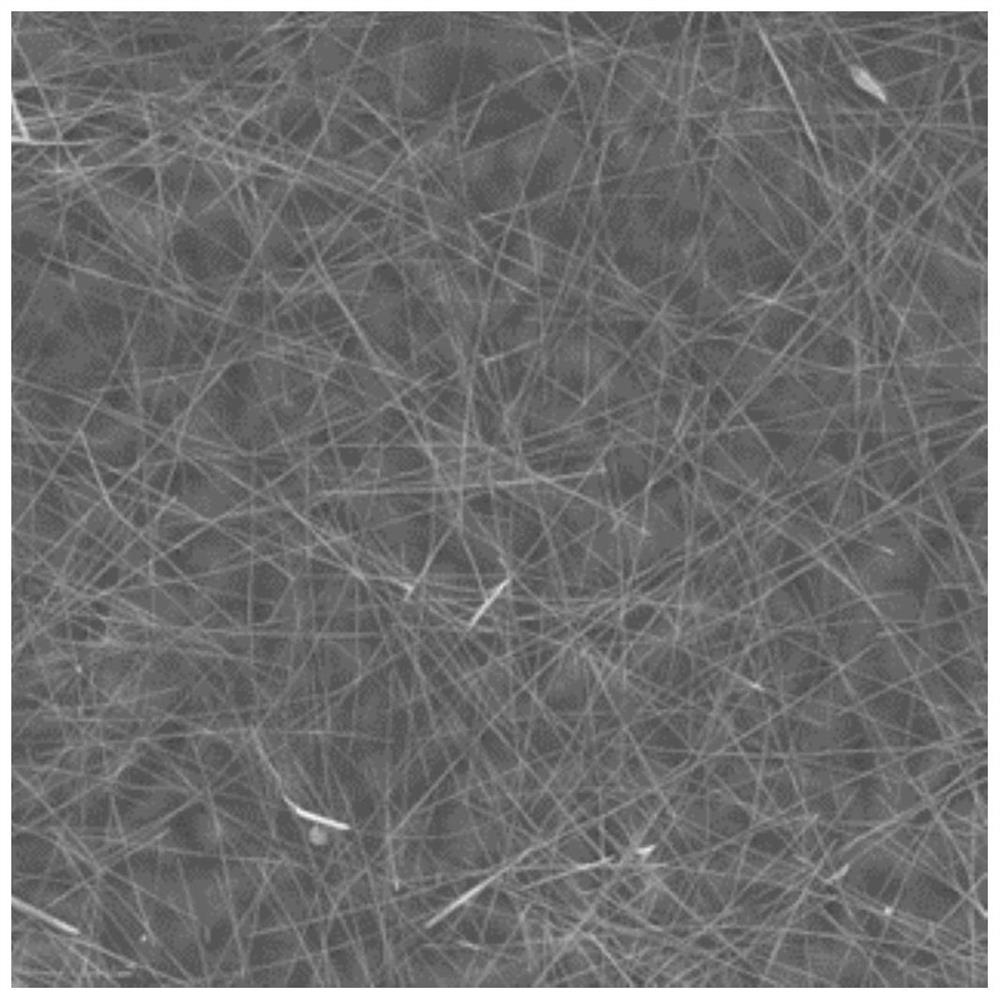

[0040] S1: The silver nanowire mother liquor is prepared by the conventional alcohol-thermal method, and the silver nanowire mother liquor in the silver nanowire mother liquor is as follows figure 1 As shown, the diameter is 100-150 nm, and the length is 25-35 μm.

[0041] Take 0.5L of silver nanowire mother liquor and place it in a beaker, take normal temperature deionized water in a ratio of 1:10 with the silver nanowire mother liquor, and add it to the beaker to dilute the silver nanowire mother liquor;

[0042] The beaker was placed in a water bath at 30° C. and stirred for 2 hours at a stirring speed of 500 r / min to obtain a silver nanowire dispersion.

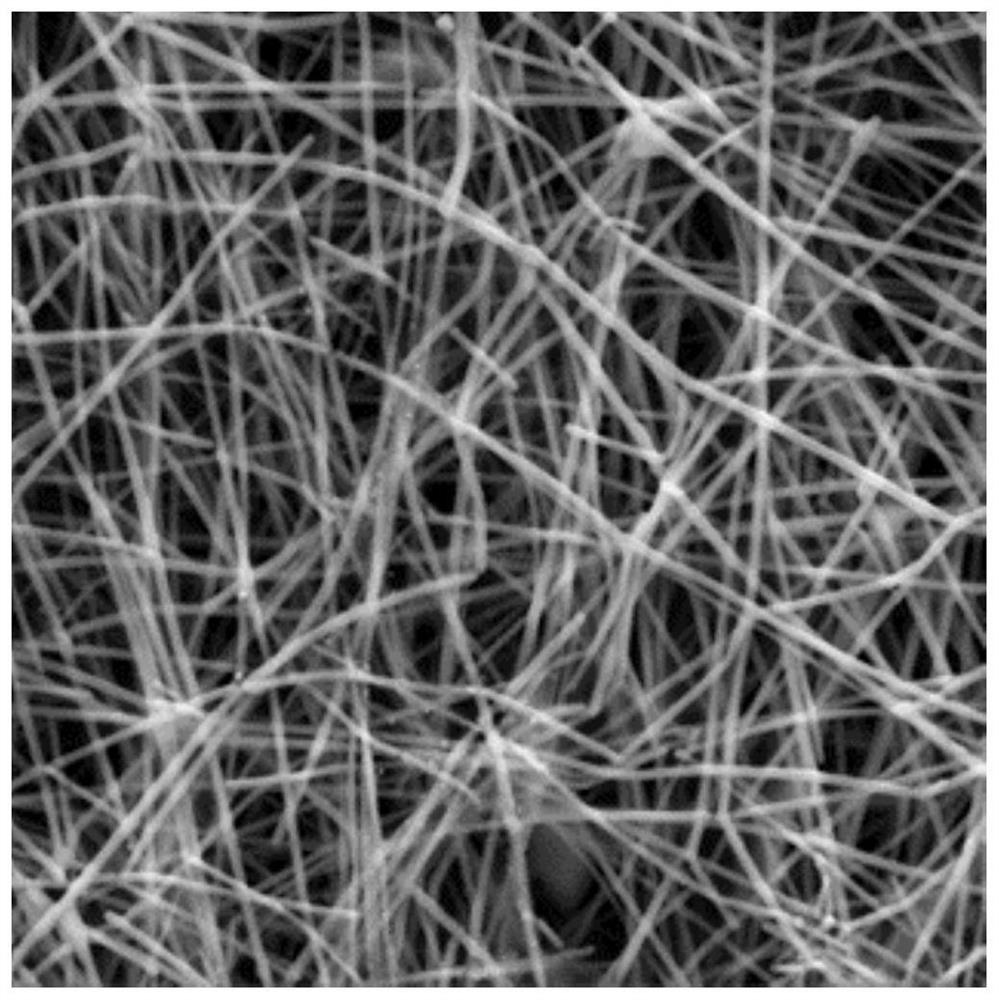

[0043] S2: filter the silver nanowire dispersion liquid under a pressure of 0.5 MPa to form a wet nanowire silver fil...

Embodiment 2

[0047]This embodiment provides a method for preparing a nanowire silver film for encapsulation and interconnection of large-scale power semiconductor integrated circuits, including the following steps:

[0048] S1: A silver nanowire mother liquor is prepared by a conventional alcohol-thermal method, and the silver nanowire mother liquor has a diameter of 50-80 nm and a length of 20-33 μm.

[0049] Take 0.7L of silver nanowire mother liquor and place it in a beaker, take normal temperature deionized water in a ratio of 1:16 with the silver nanowire mother liquor, and add it into the beaker to dilute the silver nanowire mother liquor;

[0050] The beaker was placed in a water bath at 50° C. and stirred for 0.5 h at a stirring speed of 500 r / min to obtain a silver nanowire dispersion.

[0051] S2: filter the silver nanowire dispersion liquid under a pressure of 0.5 MPa to form a wet nanowire silver film. The filter press membrane in this embodiment is a hydrophilic polytetrafluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap