Railway vehicle

A technology for rail vehicles and vehicle bodies, applied in the field of rail vehicles, can solve the problems of easy deformation of subsequent interfaces, difficult adjustment, low contour matching, etc., and achieve the effects of ensuring stability and forming quality, and strengthening deformation control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The embodiment of the present invention discloses a rail vehicle to solve the problems that the existing metal skin and metal frame have high rigidity after welding, and when manufacturing errors occur in the later stage, it is difficult to adjust, the subsequent interface is easily deformed, and the contour matching degree is low.

[0068] In order to make the technical solutions and advantages in the embodiments of the present application clearer, the exemplary embodiments of the present application will be further described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present application, and Not an exhaustive list of all embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

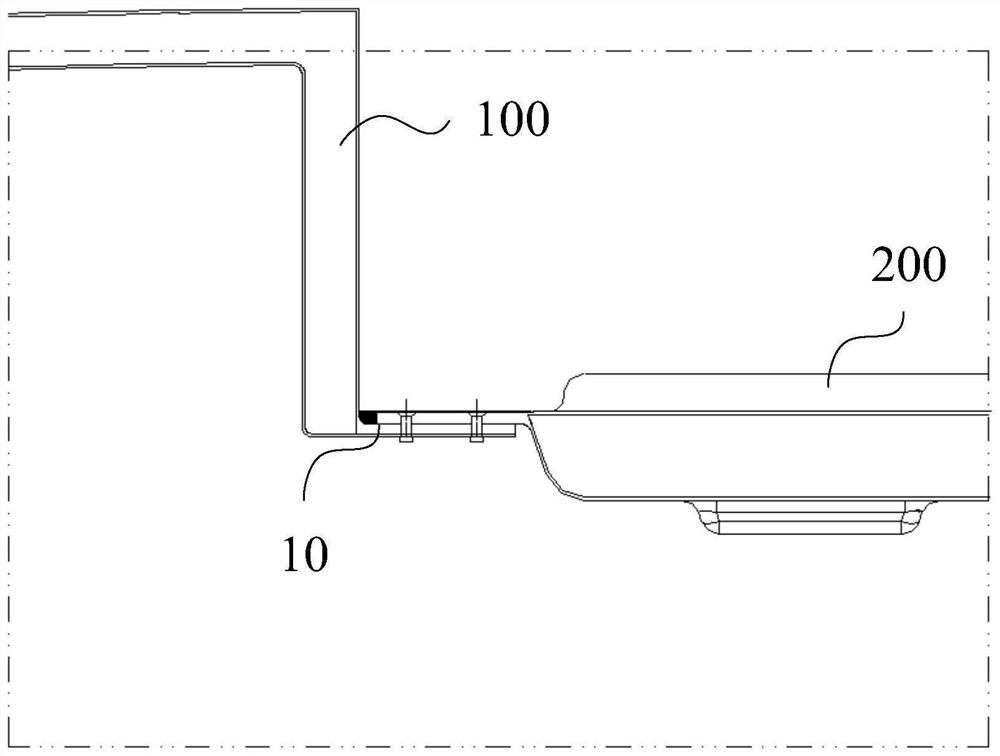

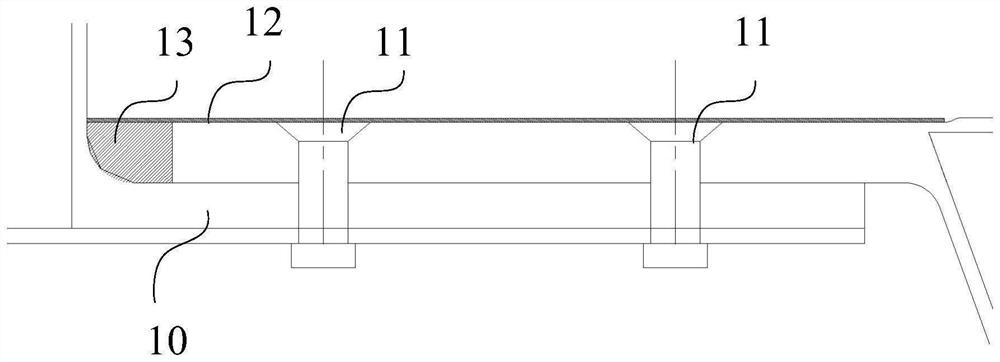

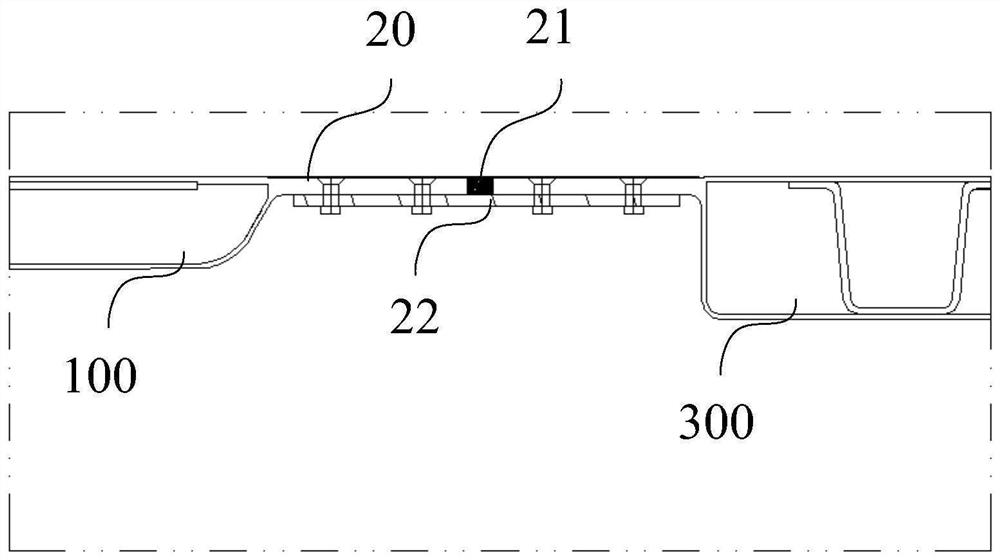

[0069] see Figure 1-8 , figure 1 A schematic diagram of a connection str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com