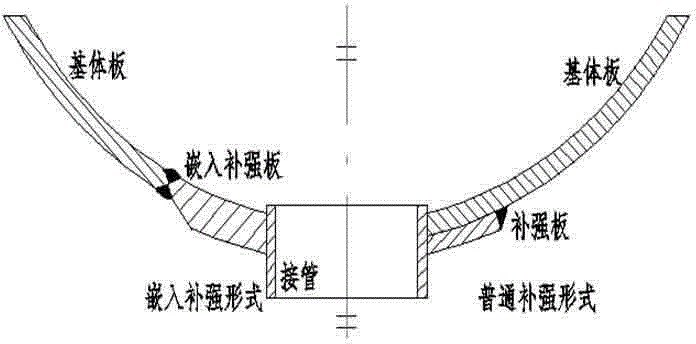

Construction technology of embedded reinforcing structure for large-orifice pipe of container

A technology for reinforcing structure and construction process, applied in manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of equipment shutdown, complex manufacturing and heat treatment process, welding quality control, heat treatment tooling and deformation prevention process, etc. Guarantee the quality of manufacturing, optimize the effect of assembly and heat treatment tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in combination with specific embodiments.

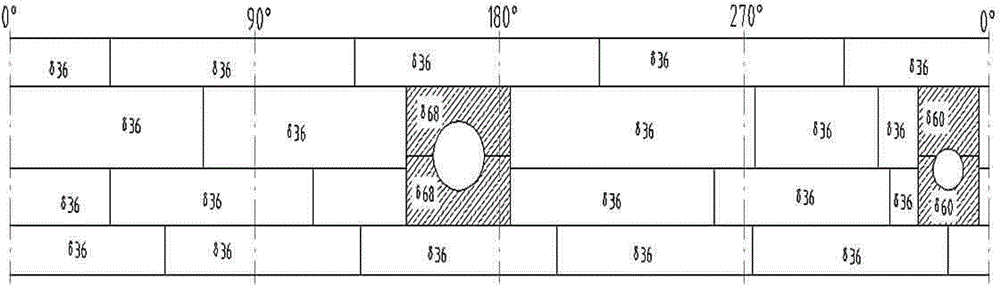

[0045] The construction technology of the embedded reinforcing structure of the large opening of the container involved in the present invention is suitable for the manufacture of the large opening embedded reinforcing structure of the reactors, regenerators, large storage tanks and other shells of the petrochemical industry. Specifically include the following steps:

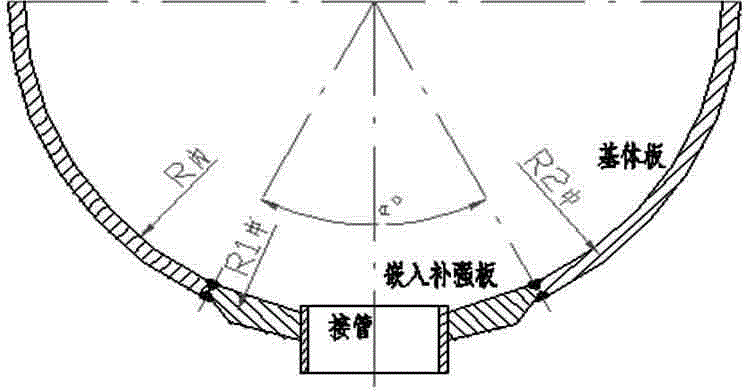

[0046] Step 1: Determine the cutting length of the embedding reinforcement plate and the base plate of the cylinder:

[0047] (1) Cutting length S1=(2·π·R1 中 / 360)*α

[0048] Among them, R1 中 is the middle diameter of the embedded reinforcement, and α is the central angle of the embedded reinforcement plate;

[0049] (2) Cutting length of base plate S2=(2·π·R2 中 / 360)*(360-α)

[0050] Among them, R2 中 is the median diameter of the base plate, and α is the central angle of the embedded reinforcing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com