A processing drill for fiber-reinforced resin matrix composites

A fiber-reinforced resin and composite material technology, which is used in metal processing equipment, drill repairs, workpieces, etc., can solve problems such as burrs and fibers that cannot be completely cut, and achieve the effect of reducing bending deformation, reducing burrs, and improving control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0012] Implementation Example 1

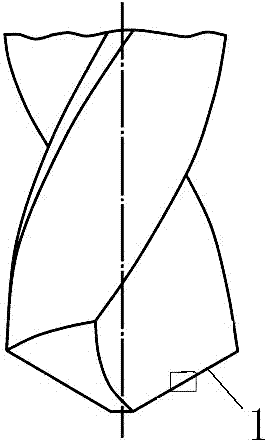

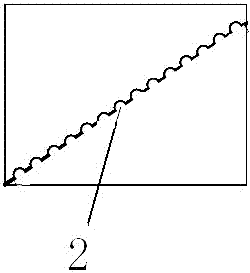

[0013] The invention provides a drill bit for processing fiber-reinforced resin-based composite materials, which includes two cutting edges, and is characterized in that: on the cutting edge of the drill bit, a plurality of semicircular grooves are arranged along the cutting edge. The diameter of the semicircular groove is equal to the diameter of the carbon fibers in the carbon fiber reinforced resin matrix composite. The distance between the centers of two adjacent semicircular grooves in the plurality of semicircular grooves is proportional to the diameter of the fibers in the fiber reinforced resin matrix composite material when the fiber content in the fiber reinforced resin matrix composite material is constant; The distance between the centers of two adjacent semicircular grooves in the circular groove is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com