A drill for processing fiber-reinforced resin-based composite materials

A fiber-reinforced resin and composite material technology, applied in the field of material processing, can solve the problems of difficult cutting of fibers and burrs, and achieve the effects of reducing bending deformation, removing burrs, and reducing burrs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

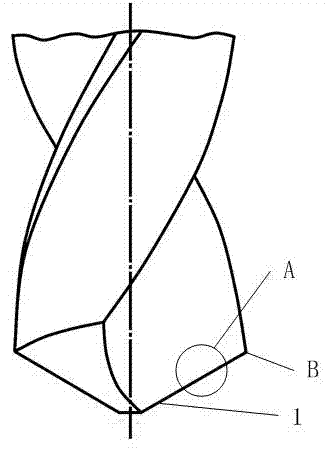

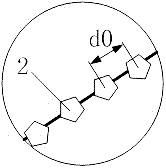

[0016] A drill bit for processing fiber-reinforced resin-based composite materials, which includes two cutting edges, and a plurality of diamond particles are arranged on the cutting edges, and the plurality of diamond particles are arranged equidistantly along the cutting edges. The diamond particles are arranged starting from the outer edge of the cutting edge at the largest diameter of the drill bit. The particle size of the diamond particles is equal to the fiber diameter in the fiber reinforced resin matrix composite material to be processed. The center distance, carbon fiber diameter and fiber content of the two adjacent diamond particles satisfy: d0=(2+1 / p)d1; where d0: center distance; d1: carbon fiber diameter; p: fiber reinforced resin matrix composite material The ratio of the volume of carbon fibers to the volume of fiber-reinforced resin matrix composites. The plurality of diamond particles are arranged on the cutting edge by welding.

[0017] The traditional dr...

Embodiment 2

[0021] A drill bit for processing fiber-reinforced resin-based composite materials, which includes two cutting edges, and a plurality of diamond particles are arranged on the cutting edges, and the plurality of diamond particles are arranged equidistantly along the cutting edges. The diamond particles are arranged starting from the outer edge of the cutting edge at the largest diameter of the drill bit. The particle size of the diamond particles is equal to twice the diameter of the fibers in the fiber-reinforced resin-based composite material to be processed. The center-to-center distance, carbon fiber diameter, and fiber content of the two adjacent diamond particles satisfy: d0=(2+1 / p)d1; where d0: center-to-center distance; d1: carbon fiber diameter; p: fiber-reinforced resin-based composite The ratio of the volume of fibers in the material to the volume of the fiber-reinforced resin matrix composite. The plurality of diamond particles are arranged on the cutting edge by e...

Embodiment 3

[0026] A drill bit for processing fiber-reinforced resin-based composite materials, which includes two cutting edges, and a plurality of diamond particles are arranged on the cutting edges, and the plurality of diamond particles are arranged equidistantly along the cutting edges. The diamond particles are arranged starting from the outer edge of the cutting edge at the largest diameter of the drill bit. The particle size of the diamond particles is equal to 1.5 times the fiber diameter in the fiber reinforced resin matrix composite material to be processed. The center-to-center distance, carbon fiber diameter, and fiber content of the two adjacent diamond particles satisfy: d0=(2+1 / p)d1; where d0: center-to-center distance; d1: carbon fiber diameter; p: fiber-reinforced resin-based composite The ratio of the volume of fibers in the material to the volume of the fiber-reinforced resin matrix composite. The plurality of diamond particles are arranged on the cutting edge by an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com