Material distributing device and bag type material loading device

A material distribution device and material technology, applied in the direction of loading/unloading, conveyor objects, transportation and packaging, etc., can solve the problem of large deformation of bagged material packages, and achieve the effect of ensuring material removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

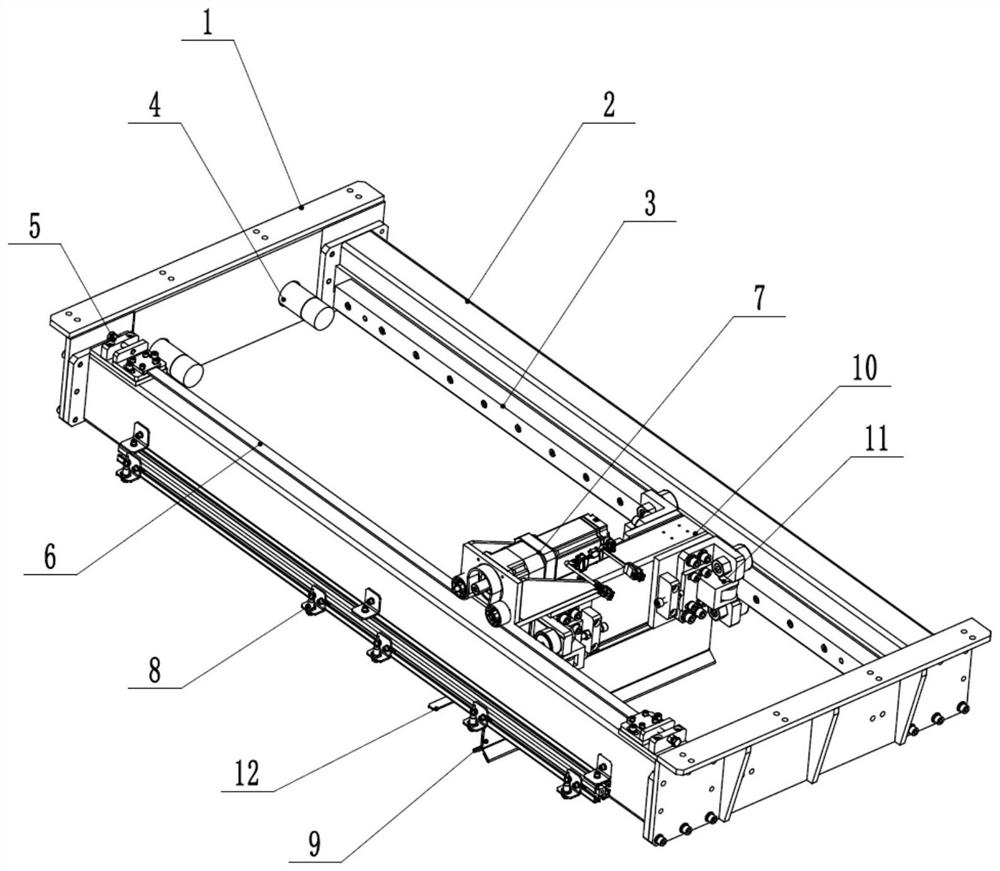

[0043] The difference between the second embodiment and the first embodiment is that the guide structure 11 may include four rolling bearings, two of which are located on the upper surface of the shifting guide rail 3 and two are located on the lower surface of the shifting guide rail 3 . Such a structure makes the operation of the shifting assembly more stable, and when the shifting assembly is shaken, the four roller bearings can form better limit constraints.

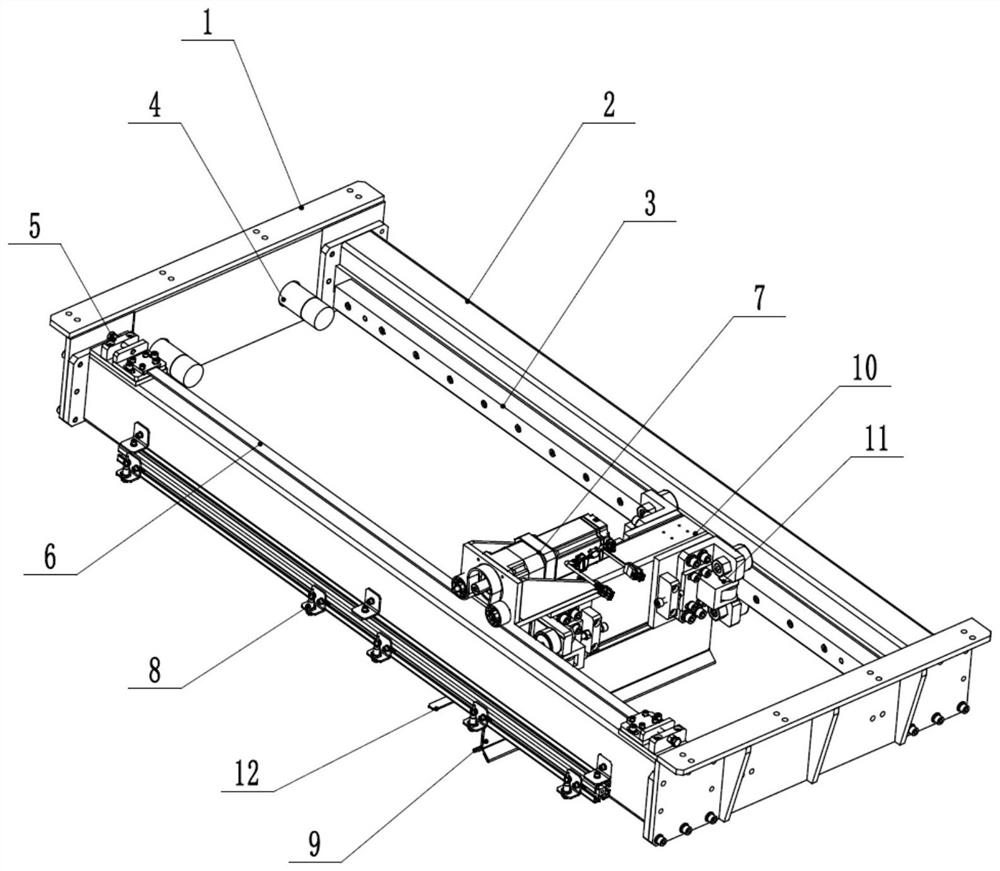

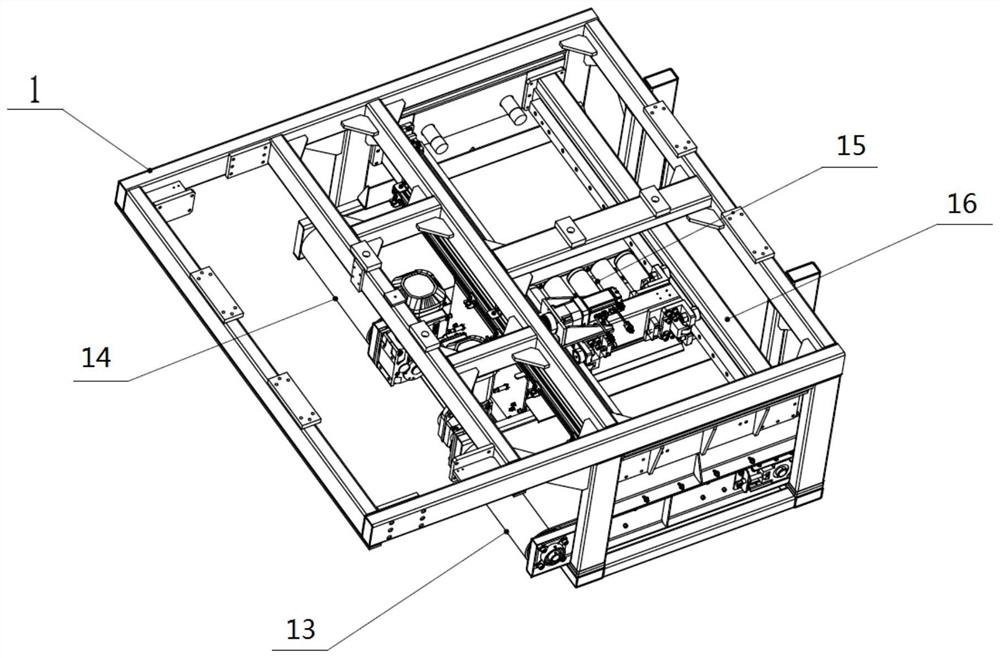

[0044] A material distributing device in Embodiment 2 includes: a mounting frame assembly and a material shifting assembly. The material shifting assembly includes a fixed frame, a driving part and a material shifting plate 9, the fixed frame is movably installed on the mounting frame, the driving part is fixedly mounted on the mounting frame, and the driving part cooperates with the mounting frame to drive the mounting frame to move relative to the mounting frame , The shifting plate 9 is fixedly installed on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com