Railway signal lamp insulation installation and debugging ladder

A technology for railway signal lights, installation and debugging, applied in the direction of ladders, buildings, building structures, etc., can solve the problems of easily soiling clothes, hidden dangers, increasing the use of laborers, etc., and achieves the effect of stable contact parts and increased reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

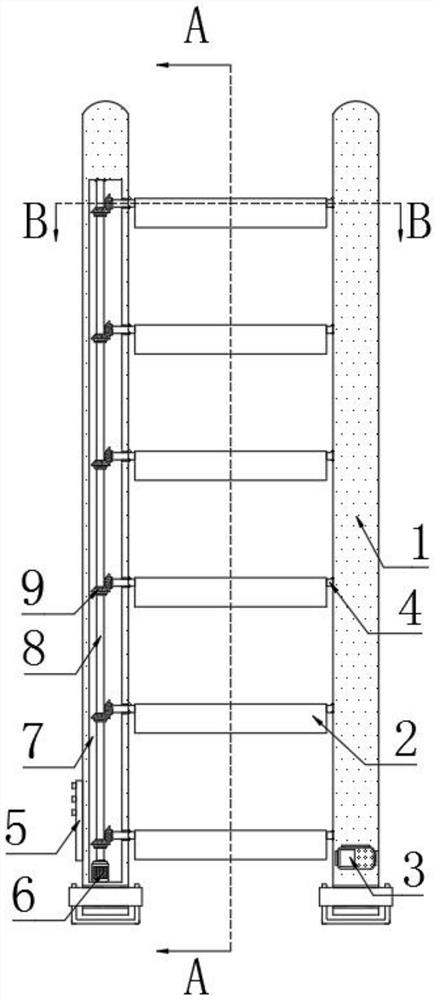

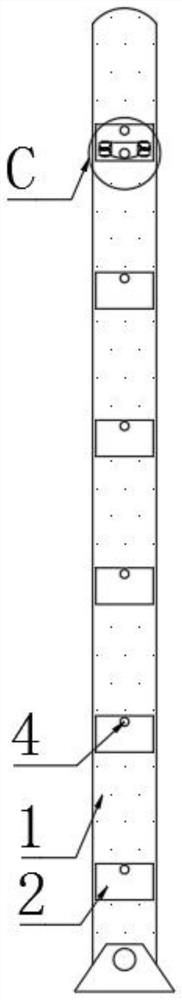

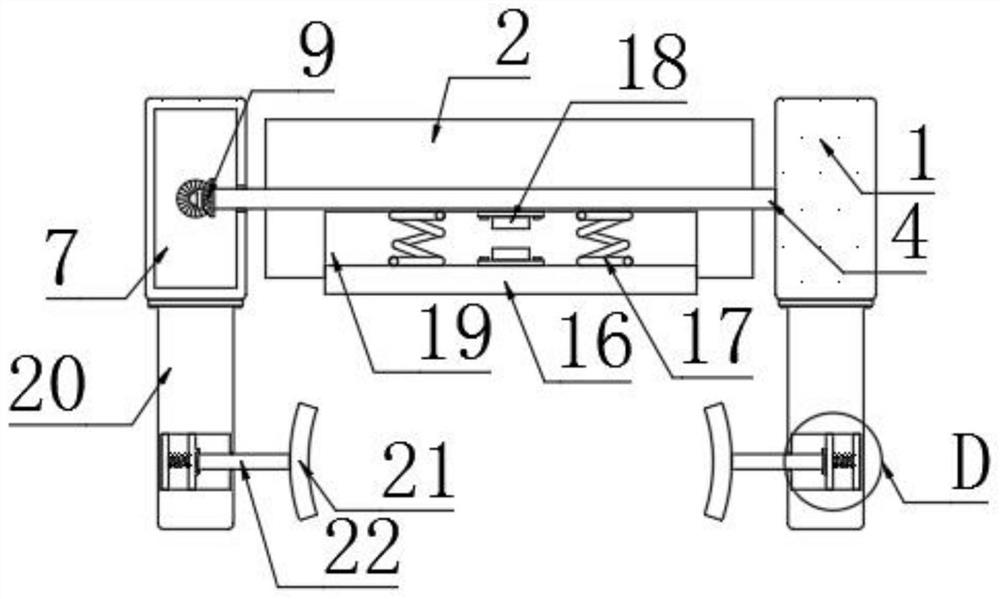

[0025] refer to Figure 1-5 , a railway signal lamp insulation installation and debugging ladder, comprising two vertical bars 1, a control panel 5 is installed on the left side of the vertical bar 1 on the left side, a power supply 3 is arranged in the vertical bar 1 on the right side, and the two vertical bars A plurality of first rotating rods 4 are rotatably connected between the adjacent surfaces of 1, and pedals 2 are set on the plurality of first rotating rods 4, and the plurality of pedals 2 are fixedly connected with the corresponding first rotating rods 4, located on the left The vertical rod 1 on the side is provided with a vertical chamber 7, and a rotating mechanism is provided in the vertical chamber 7. The rotating mechanism includes a driving motor 6 arranged at the bottom of the vertical chamber 7. The driving motor 6 is a three-phase AC motor, and the output of the driving motor 6 The end of the shaft is fixedly connected with a second rotating rod 8, the upp...

Embodiment 2

[0037] refer to Figure 6-7 , The difference between this embodiment and Embodiment 1 is that a transition chamber 29 and a contraction chamber 27 are provided in the vertical rod 1 on the right side, the contraction chamber 27 is located on the right side of the transition chamber 29, and a piston is arranged in the contraction chamber 27 33. The piston 33 is slidingly connected to the inner wall of the contraction cavity 27. The lower end of the piston 33 is elastically connected to the inner bottom of the contraction cavity 27 through the energizing spring 28. The power supply 3, the main switch and the energizing spring 28 form a circuit through wires. The contraction cavity 27 is located at The space above the piston 33 communicates with the outside world through the intake pipe 31. The space above the piston 33 communicates with the space on the right side of the transition chamber 29 through the air outlet pipe 32. The air inlet pipe 31 and the air outlet pipe 32 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com