Modular wind power blade chordwise block connecting structure

A wind power blade and connection structure technology, applied in the field of modular wind power blade chordwise block connection structure, can solve the problems of poor traffic conditions, increased cost, increased weight of metal connections, etc., to reduce blade weight, meet sealing requirements, accelerate effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

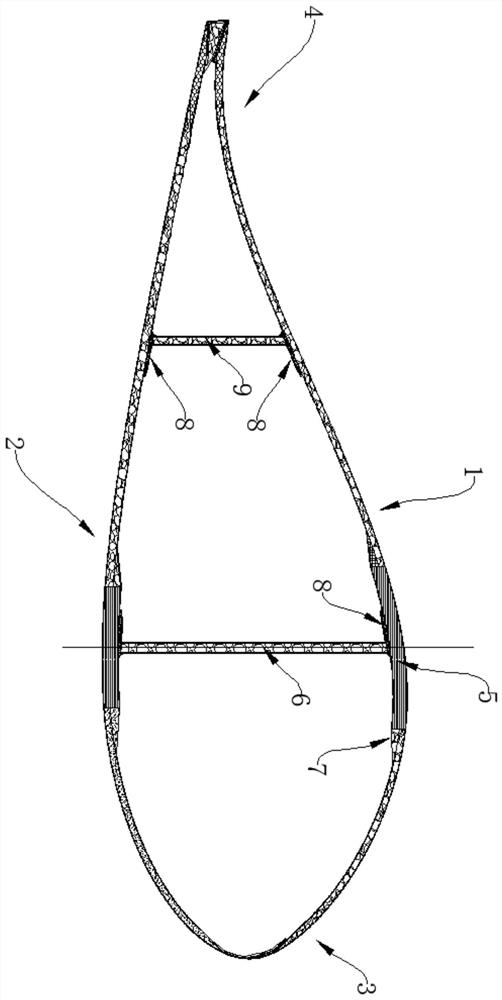

[0045] like figure 1The modular wind power blade string is made toward the block connection structure, including the blade body, the blade body including the winding surface 1 and the backshop 2; and the leaf surface length direction is formed by the skin surface 1 and the leaf surface 2 The leading edge housing 3 and the trailing edge housing 4, between the winding surface 1 and the trailing edge housing 4 are provided on one side of the welding surface 1 and the back wind surface 2; provided in the blade body cavity The internal shear belle 6 extends between the welding surface 1 and the back wind surface 2 for supporting the main beam cap 5; wherein the main beam 5 located at the winding surface 1 and the back wind surface 2 is bonded to the front edge housing. The skin housing 3 and the rear edge housing 4 and the main beam cap 5 are spliced to the main beam cap 5 to form a wind power blade profile.

[0046] Specifically, the adhesive structure at the skin structure 7 overco...

Embodiment 2

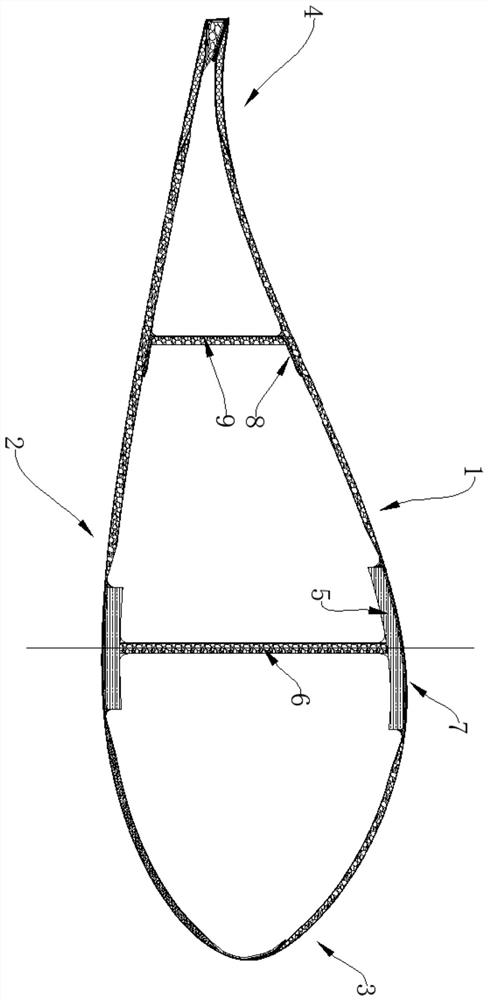

[0052] The difference from the embodiment is that if figure 2 The main beam cap 5 is provided in the inner mood of the skin structure 7, and the inner mood is bent toward the outer side, the leading edge housing 3 and the trailing edge case 4 are integrally formed in the strings, and the main beam cap is integrally formed. 5 and the shear on the ablated belle 6 are bonded to the inside of the inner mood.

[0053] Specifically, the leading edge housing 3 and the rear housing 4 are integrally formed in the strings, reducing the connection point, improving the overall stability, and is integrally formed by the anti-shear external beam 5, and is bonded to fix The shear ability is further improved in the inside of the inner mood of the outer side.

Embodiment 3

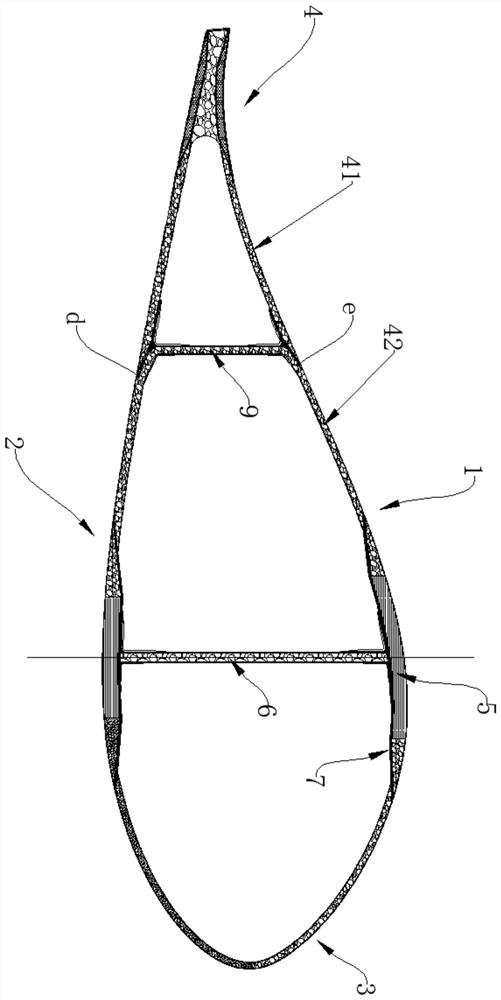

[0055] The difference from the first and embodiments of the embodiment is that the blade is divided into three pieces in the direction of the strings, and adhesive fixation, avoiding the bonding problem of the front and rear edges, and the main beam cap 5 is disposed in the skin structure 7 outside.

[0056] like Figure 3-9 The modular wind power blade string is made toward the block connection structure, including the blade body, the blade body including the winding surface 1 and the backshop 2; and the leaf surface length direction is formed by the skin surface 1 and the leaf surface 2 The leading edge housing 3 and the trailing edge housing 4, between the winding surface 1 and the trailing edge housing 4 are provided on one side of the welding surface 1 and the back wind surface 2; provided in the blade body cavity The internal shear belle 6 extends between the welding surface 1 and the back wind surface 2 for supporting the main beam cap 5; wherein the main beam 5 located at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com