Electronic cigarette heating system

A heating system and e-cigarette technology, applied in the field of e-cigarettes, can solve problems such as uneven heating effect, heating and atomization of all e-liquids, and affecting the user's smoking experience, so as to achieve the effect of improving the heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

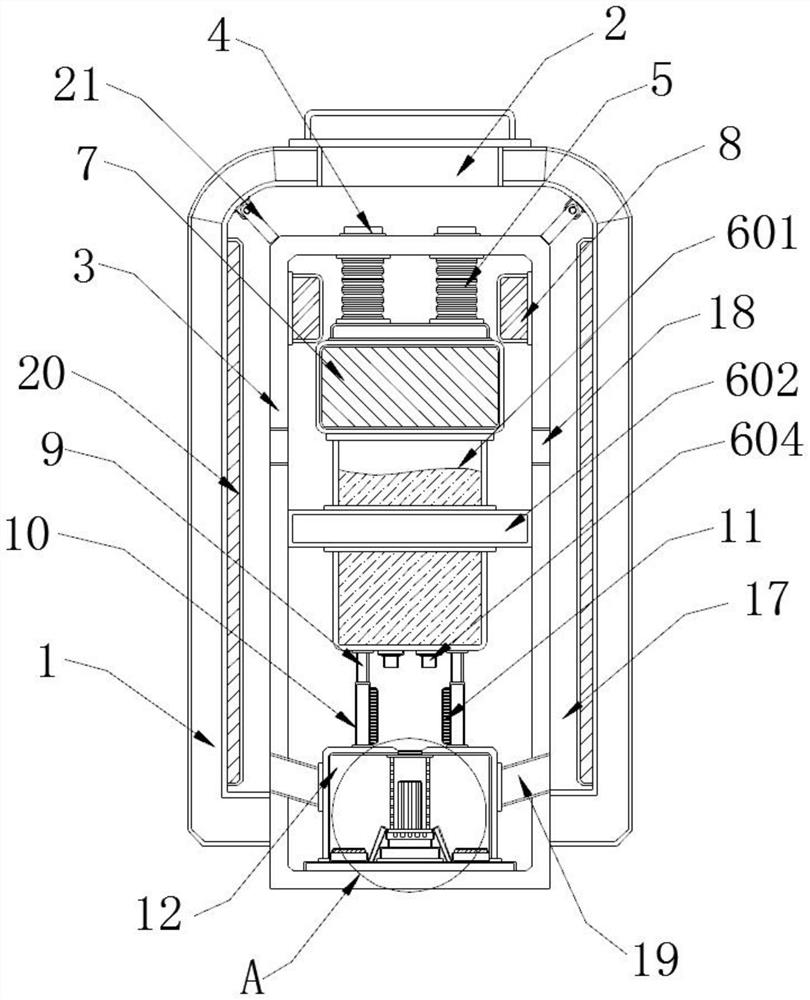

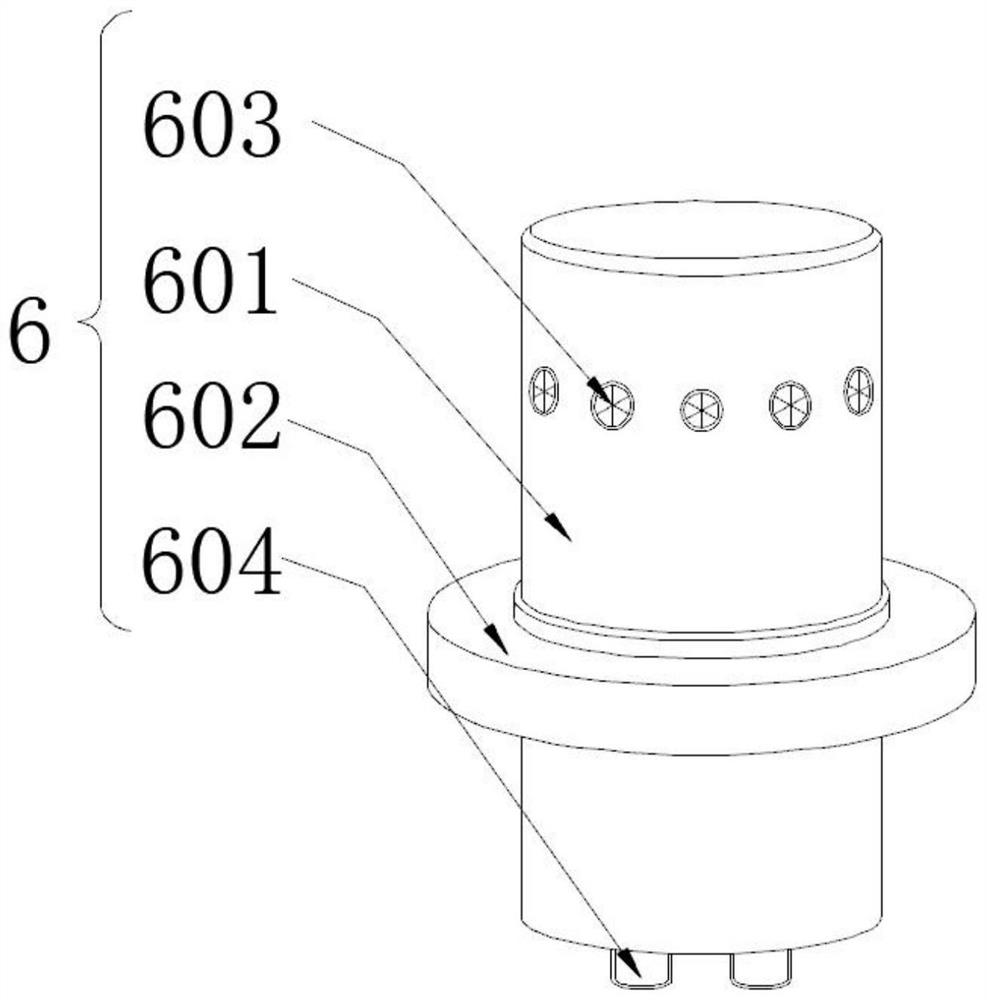

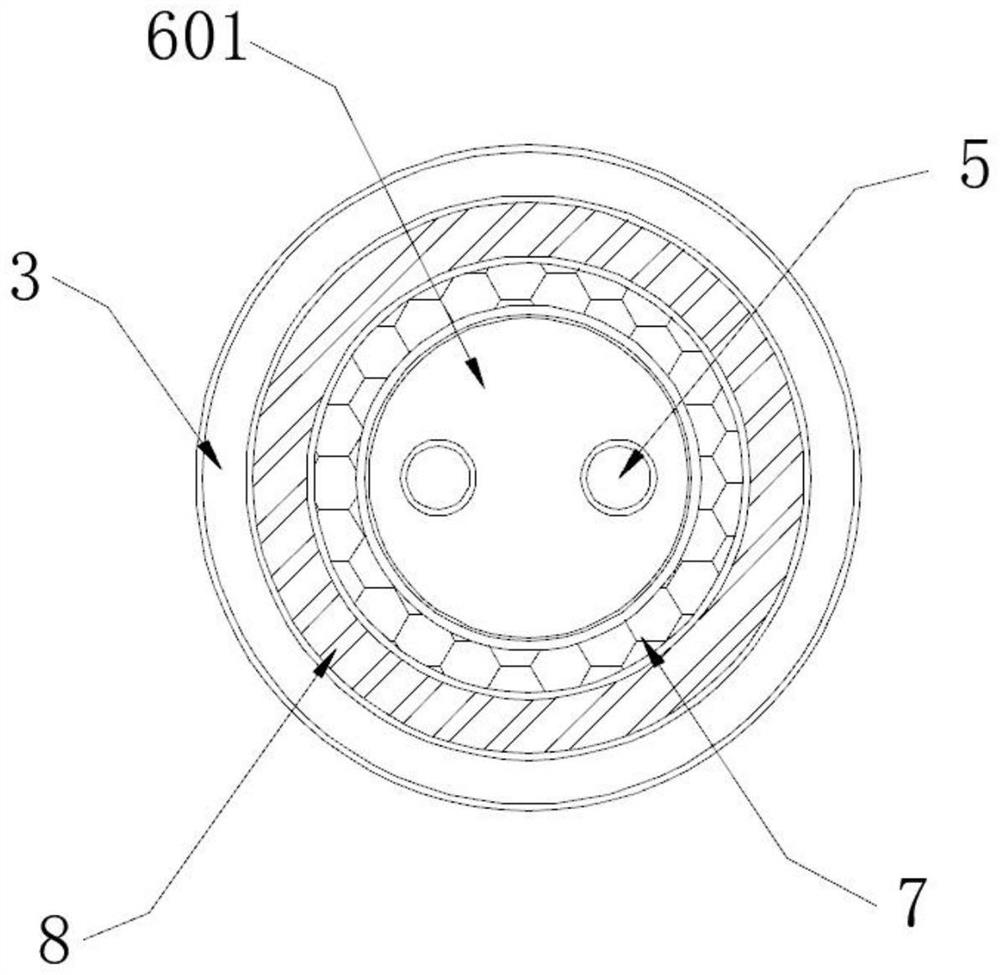

[0030] see Figure 1-8 , the present invention provides a technical solution: an electronic cigarette heating system, including an outer shell 1, an oil storage assembly 6 and a heating box 12, a suction port 2 is opened on the outer side of the top of the outer shell 1, and the inner side of the outer shell 1 is provided with a The interlayer seat 3 is provided with a communication port 4 on the outer side of the top of the interlayer seat 3, and the outer side of the bottom of the communication port 4 is connected with a telescopic air bag 5, and the oil storage assembly 6 is arranged on the bottom outer side of the telescopic air bag 5, and the outer side of the oil storage assembly 6 is arranged There is an extruding air bag 7, an extruding plate 8 is connected to the inner surface of the compartment seat 3, a lifting plate 9 is arranged on the outside of the bottom of the oil storage assembly 6, and a heating plate 10 is connected to the outside of the lifting plate 9, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com