A Catalytic Cracking Method for Improving Liquid Yield

A catalytic cracking and catalytic cracking device technology, applied in the field of catalytic cracking to improve liquid yield, can solve problems such as inability to effectively reduce coke yield, and achieve the effects of shortening gasification time, significant economic benefits, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

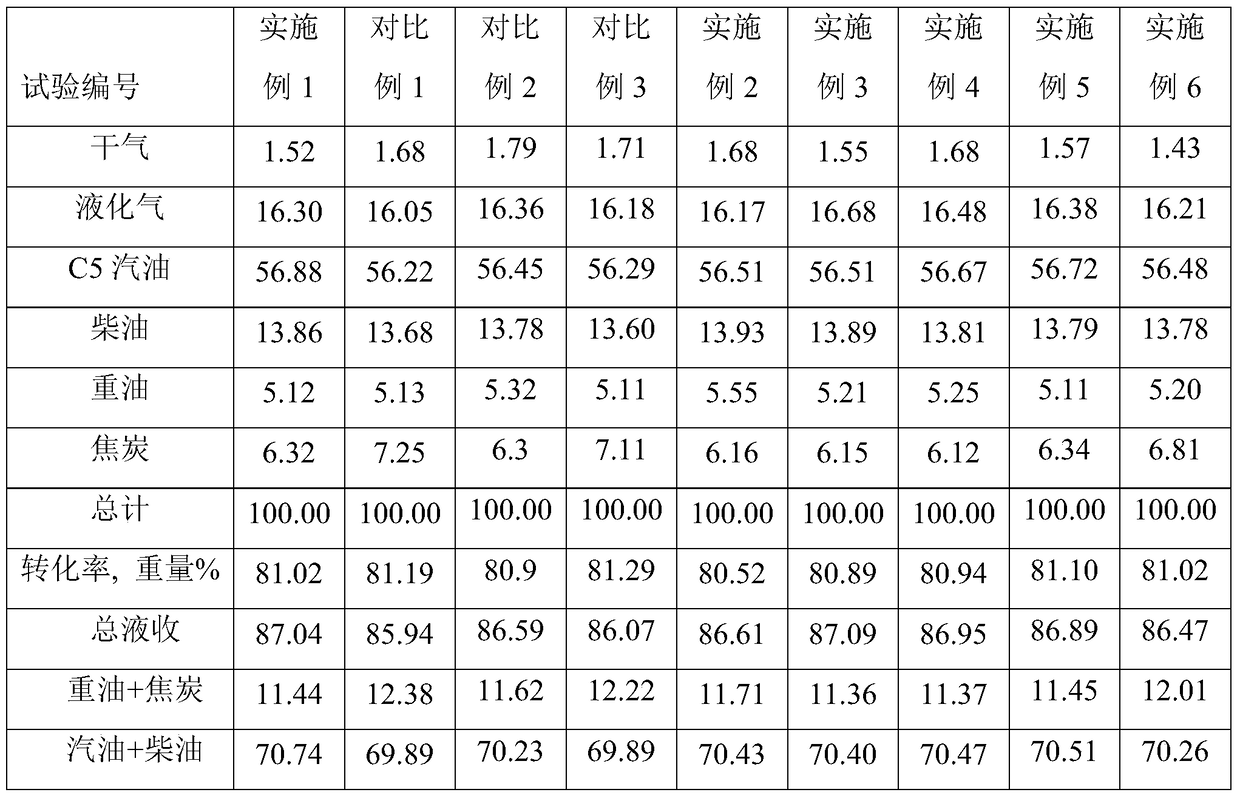

[0030] This example is used to illustrate the catalytic cracking method for improving liquid yield provided by the present invention.

[0031] Take 2000 kg of atmospheric residual oil, add 2 kg of ethoxy nonyl phenol and 2 kg of vacuum wax oil in sequence, fully stir and mix to obtain modified feed oil A. Then, the feedstock oil A is injected into a fluidized bed reactor to perform a catalytic cracking reaction, wherein the reaction temperature is 510°C, and the space velocity is 25h -1 , The weight ratio of agent to oil is 6. The resulting product distribution list is shown in Table 3.

Embodiment 2

[0039] This example is used to illustrate the catalytic cracking method for improving liquid yield provided by the present invention.

[0040] Take 2000 kg of atmospheric residual oil, add 2.5 kg of ethoxy nonylphenol, 1.5 kg of antimony dialkyl dithiophosphate, and 2 kg of vacuum wax oil in sequence, and fully stir and mix to obtain modified feed oil B. Then, the feedstock oil B is injected into a fluidized bed reactor to perform a catalytic cracking reaction, where the reaction temperature is 510°C, and the space velocity is 25h -1 , The weight ratio of agent to oil is 6. The resulting product distribution list is shown in Table 3.

Embodiment 3

[0042] This example is used to illustrate the catalytic cracking method for improving liquid yield provided by the present invention.

[0043] Take 2000 kg of atmospheric residual oil, add 2 kg of dodecyl benzene sulfonic acid and 2 kg of vacuum wax oil in sequence, fully stir and mix to obtain modified feed oil C. Then, the feedstock oil C is injected into a fluidized bed reactor to perform a catalytic cracking reaction, wherein the reaction temperature is 510°C, and the space velocity is 25h -1 , The weight ratio of agent to oil is 6. The resulting product distribution list is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com