Stacking machine

A technology of stacking machines and equipment, applied in the field of stacking machines, which can solve the problems of steep conveyor belt slopes and easy creases on corrugated cardboard, so as to avoid excessively steep slopes and reduce the overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

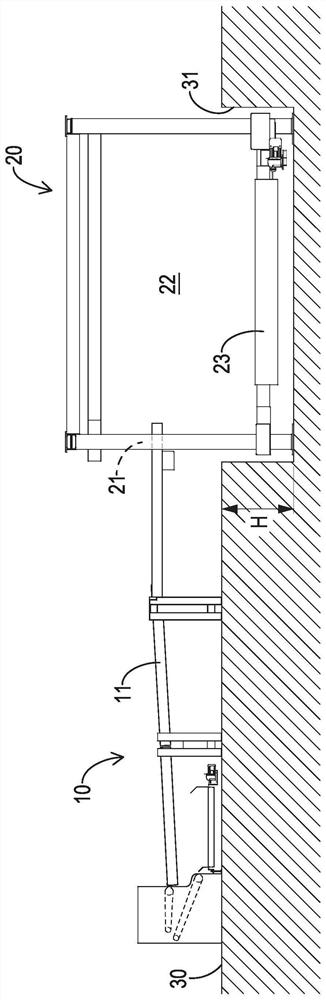

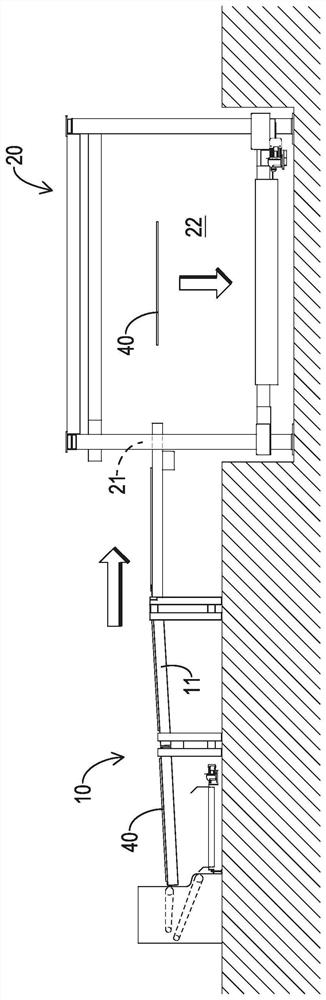

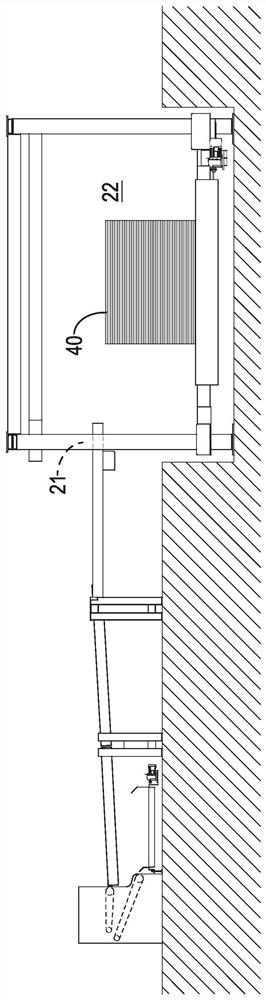

[0029] The present invention is a kind of stacking machine, the preferred embodiment of the present invention is as follows figure 1 and figure 2 As shown, the stacker is used for stacking corrugated cardboard 40, and includes a transfer device 10 and a delivery device 20, wherein:

[0030] Such as figure 1 As shown, the conveying equipment 10 is located on a horizontal plane 30, and the horizontal plane 30 is located on a first height, so that the conveying equipment 10 is located at the first height. The conveying equipment 10 is provided with a conveyor belt 11, and the conveyor belt 11 can be as figure 2 Each corrugated cardboard 40 is conveyed as shown. In a preferred embodiment of the present invention, the horizont...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap