Suspension protection construction method for high-voltage cable pipeline transversely penetrating through middle of large-span foundation pit

A technology of high-voltage cables and construction methods, which is applied in the direction of cable installation, cable installation in underground pipelines, and infrastructure engineering, and can solve problems such as hidden dangers in engineering construction quality, high construction safety risks, and heavy relocation workload. Prevent damage to flexible suspension facilities, improve safety and stability, and improve safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

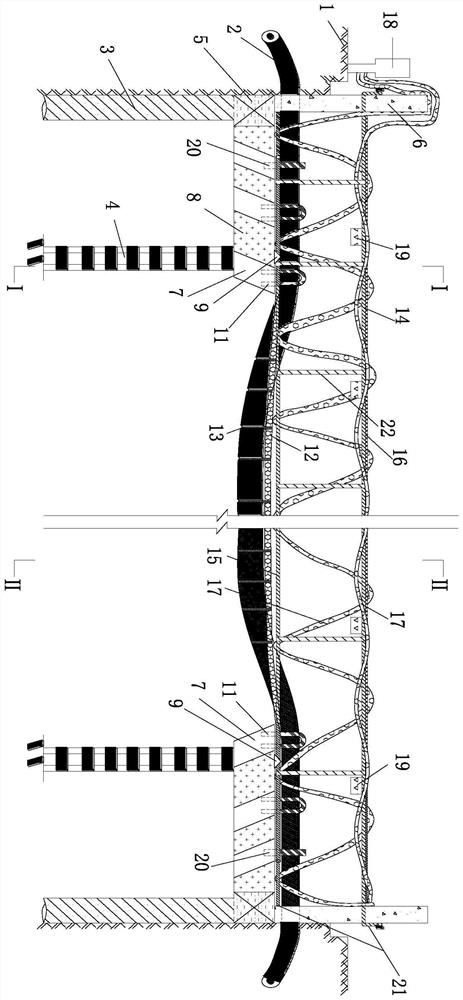

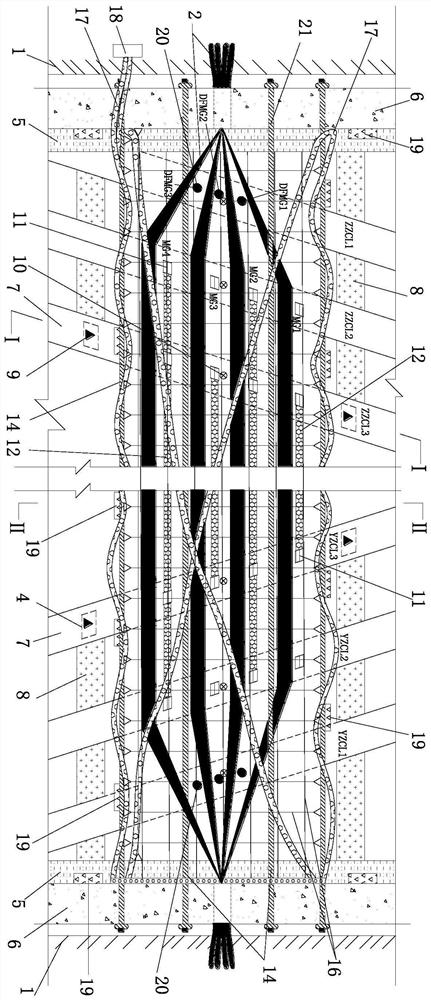

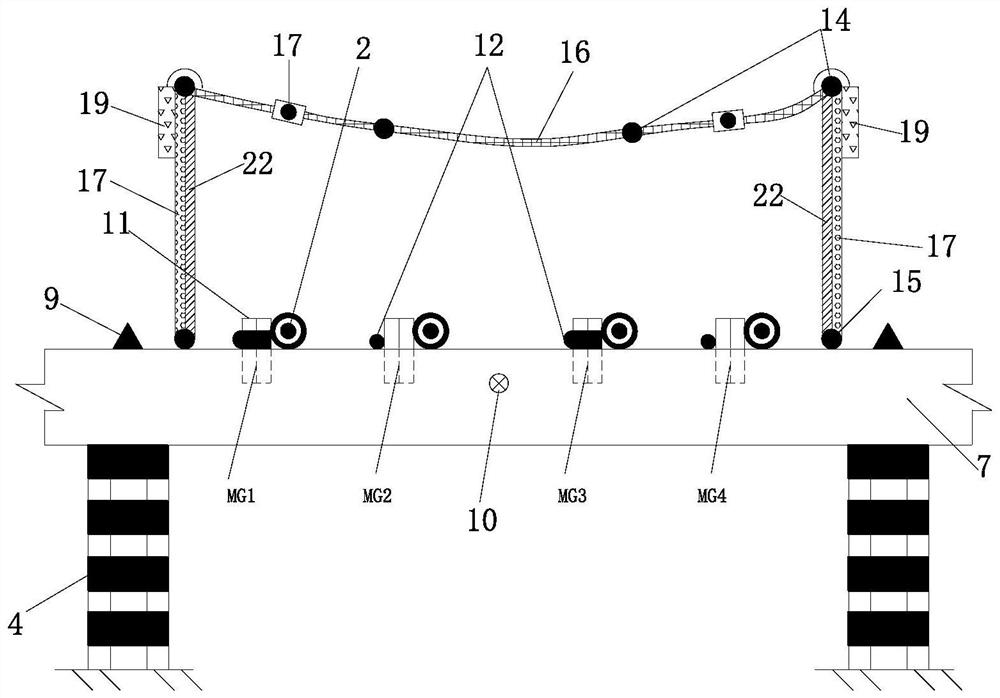

[0057] For the suspension protection construction method of the high-voltage cable pipeline crossing the middle part of the long-span foundation pit, please refer to Figure 1 to Figure 5 , which includes the following steps:

[0058] S1. Construction environment survey

[0059] Investigate and detect the underground laying depth, location, diameter, material, laying direction, cable well location, high-voltage switchgear location and surrounding environment of the high-voltage cable pipeline 2;

[0060] S2. Foundation pit structure construction in areas not affected by high-voltage cables and pipelines

[0061] In the section not affected by high-voltage cables and pipelines, construct enclosure piles 3, lattice support columns 4, crown beams 5 and retaining walls 6 in the foundation pit 1 of the underground structure;

[0062] S3. Elevation construction of high-voltage cable pipelines

[0063] S31. Pulling out the reserved length of high-voltage cable pipeline

[0064] A...

Embodiment 2

[0092] In the underground structure construction project of a rail transit station in Guangxi, in the middle of the foundation pit with a design depth of 10m and a width of 53m, a buried depth of 7.0m, YJV22-8.7 / 15kV-3×300mm 2 , 10kV four hose-type high-voltage cables, and each of them is respectively installed in a DN166 mm×8.0mm PE (polyethylene) cable protection tube; below, as Figure 1 to Figure 4 As shown, this embodiment shows the specific application of the method of the present invention in the above-mentioned engineering case, including the following steps:

[0093] S1. Construction environment survey

[0094] According to the construction drawing design of the underground structure of the station, investigate and detect in detail the underground laying depth, position, diameter, material, laying direction, cable well position, and high-voltage switchgear position of the high-voltage cable pipeline 2 (10kV hose type in this project) and the surrounding environment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com