Gas turbine air inlet system filter installation frame

A technology for air intake system and installation frame, which is applied in the field of filter installation frame, which can solve the problems of affecting the working efficiency of the air intake system, huge installation and removal workload, and short service life, so as to reduce downtime maintenance and replacement time and shorten fault repair The effect of shortening the time and shortening the installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation will be further described below in conjunction with the accompanying drawings.

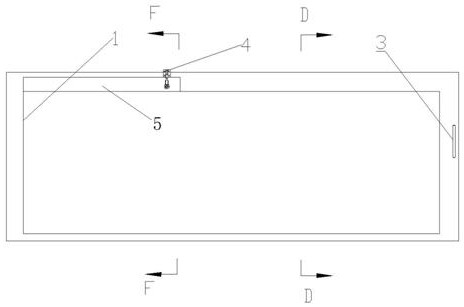

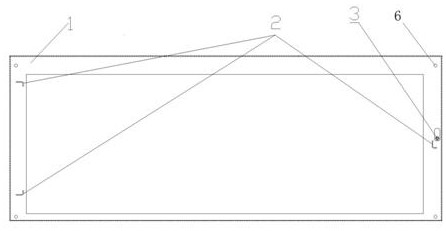

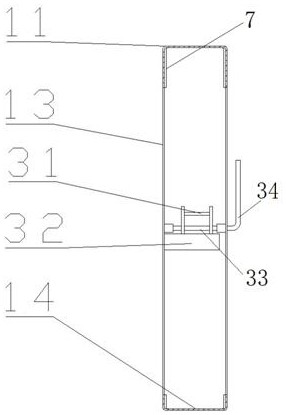

[0021] Such as Figure 1-Figure 4 As shown, a gas turbine air intake system filter installation frame includes an outer frame 1 with a U-shaped structure in cross section, a rectangular cutout 5 is provided on the outer frame 1, and one side of the rectangular cutout 4 is installed on the outer frame 1. The clamping mechanism 4, the outer frame 1 is also provided with a clamping device 3, a limiting device 2 and a mounting hole 6 respectively.

[0022] The outer frame 1 is composed of an upper U-shaped bending piece 11, a left U-shaped bending piece 12, a right U-shaped bending piece 13, and a lower U-shaped bending piece 14, all of which are U-shaped in cross-section. All towards the inner side of the outer frame 1, the rectangular cutout 5 is provided on the side of the upper U-shaped bending piece 11, and the left U-shaped bending piece 12 and the right U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com