Electromagnetic relay with pressure spring

A technology of electromagnetic relays and compression springs, which is applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems such as assembly deformation, compression spring displacement, and easy generation of scraping, so as to reduce plastic scraps, prevent assembly deformation, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

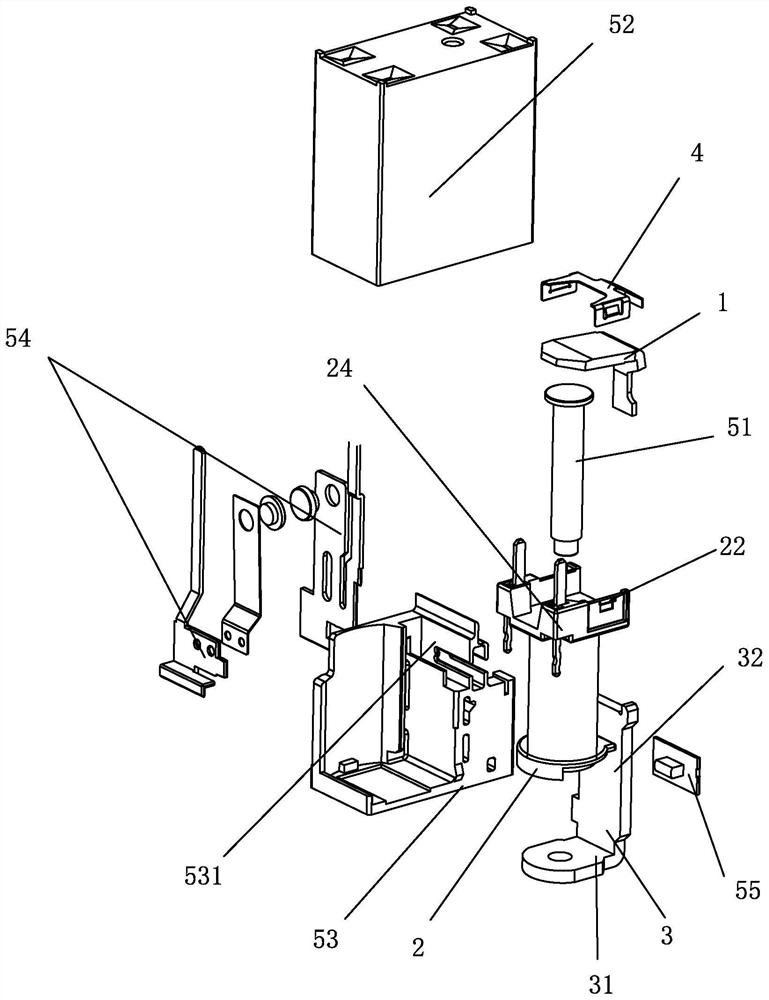

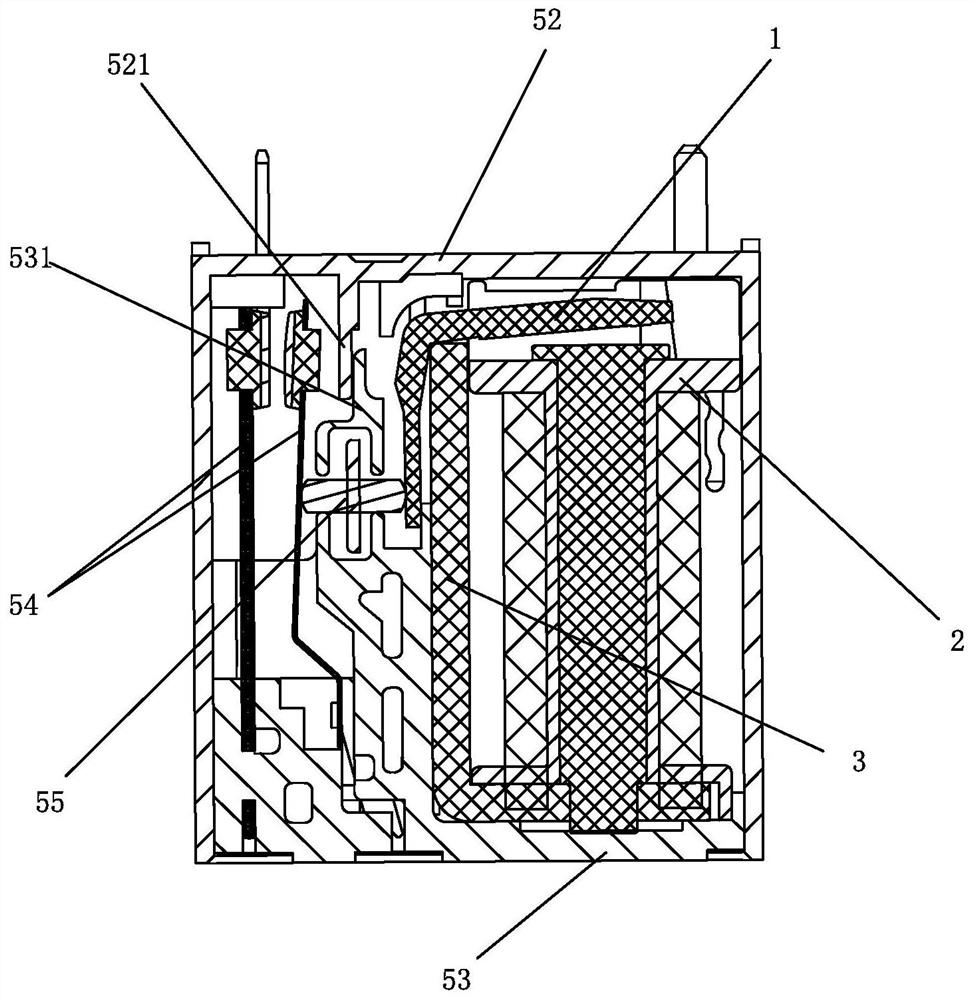

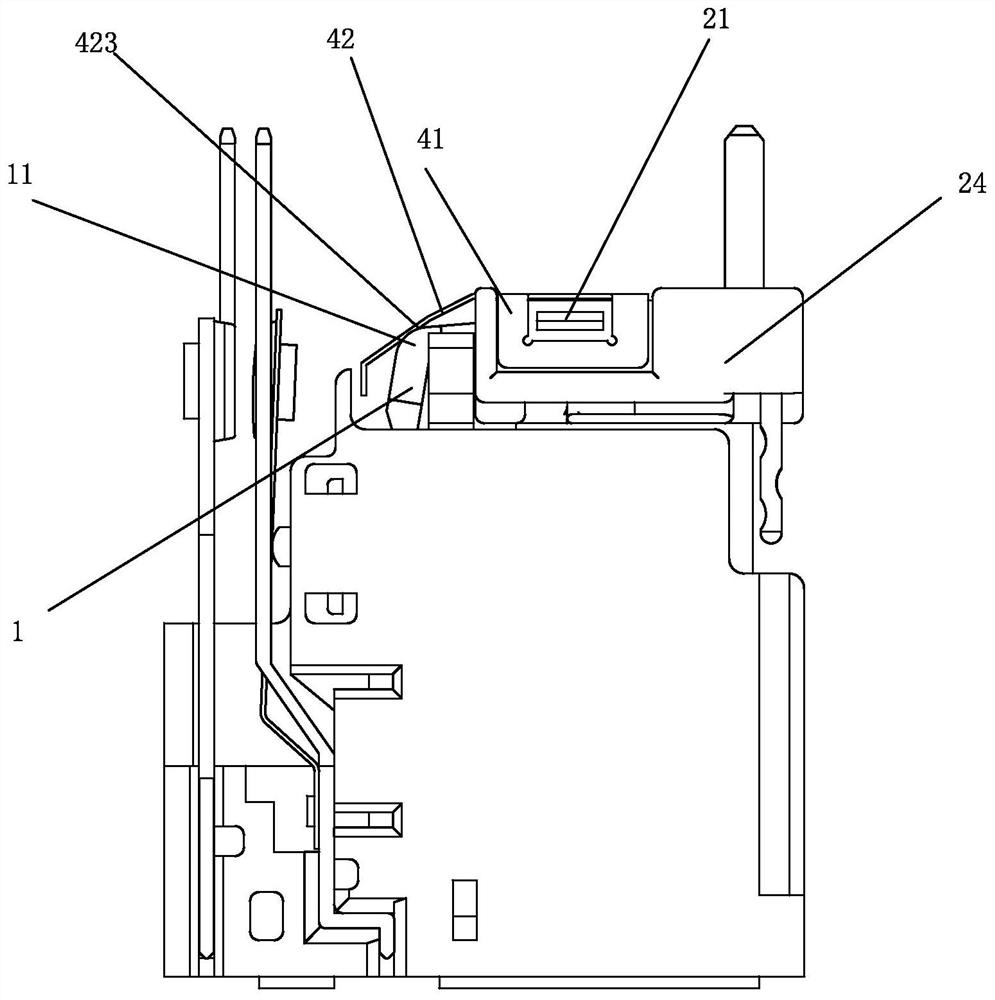

[0033] see Figure 1 to Figure 10 As shown, an electromagnetic relay with a compression spring of the present invention includes an armature 1, a coil frame 2, a yoke 3 and a compression spring 4; the yoke 3 is installed next to the coil frame 2; the armature 1 Fitted at the knife edge of the yoke 3; the compression spring 4 includes a fixing part 41 and a spring part 42, and the compression spring 4 is fixed on the coil frame 2 through the fixing part 41, so that the elastic part of the compression spring 4 The part 42 limits the armature 1 at the knife edge of the yoke 3, so that the armature 1 can swing around the knife edge of the yoke 3; the fixing part 41 of the compression spring 4 is U-shaped, and the coil frame 2 A part of it fits in the U-shaped U-shaped mouth of the compression spring 4, and a first protrusion 21 and a second protrusion protrude outwards from the opposite sides of a part of the coil former 2, respectively. 22. The U-shaped sidewalls of the compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com