Automatic surface oil wiping machine for vehicle-mounted glass

A surface oiling machine and glass technology, applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., can solve the problems affecting the working efficiency of mechanical wiping equipment, and achieve the effect of compact structure, easy maintenance and saving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

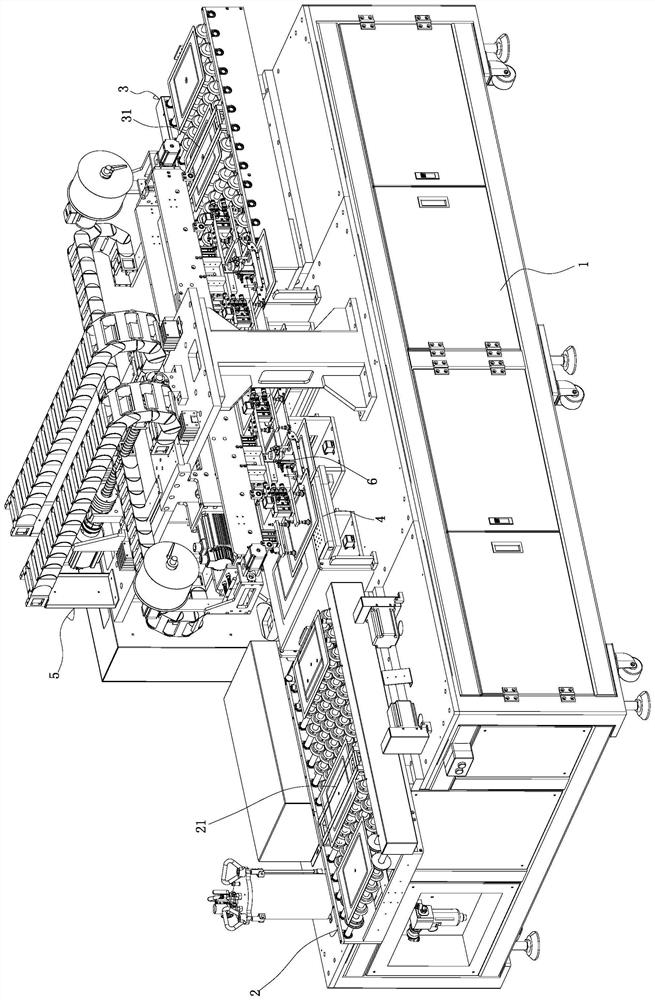

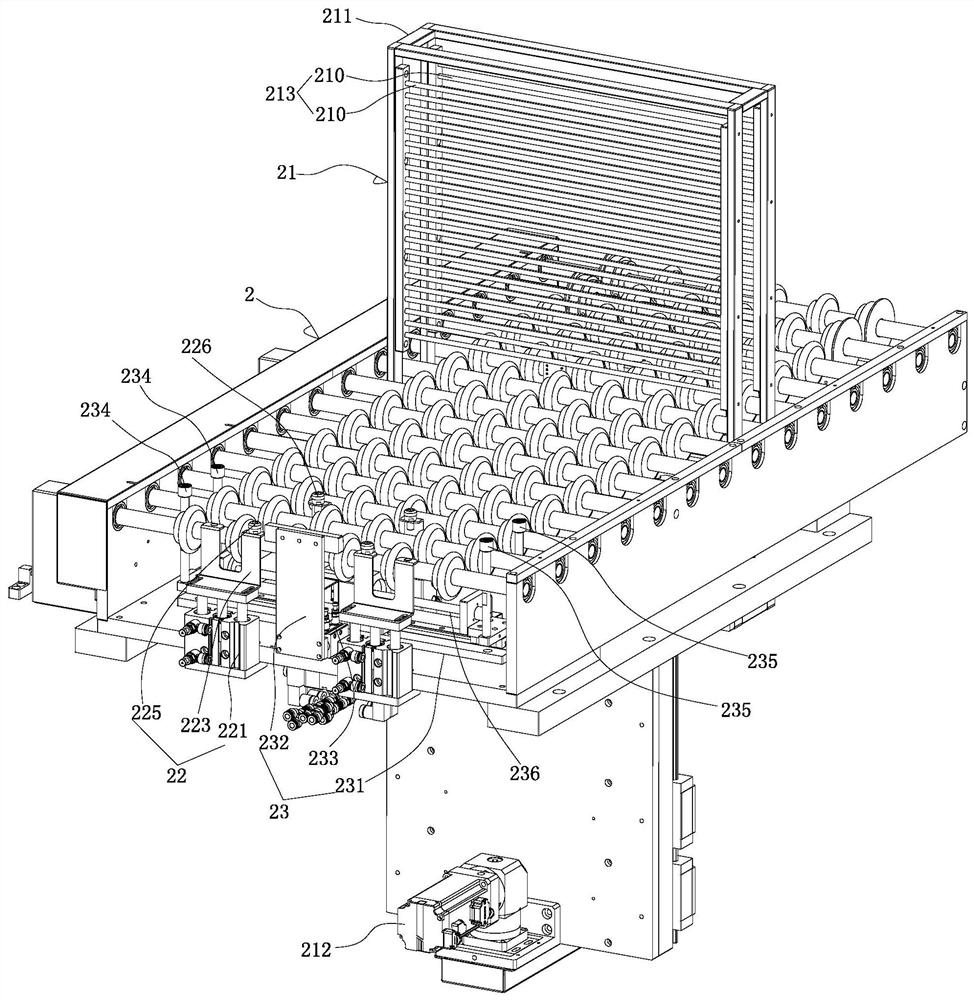

[0031] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

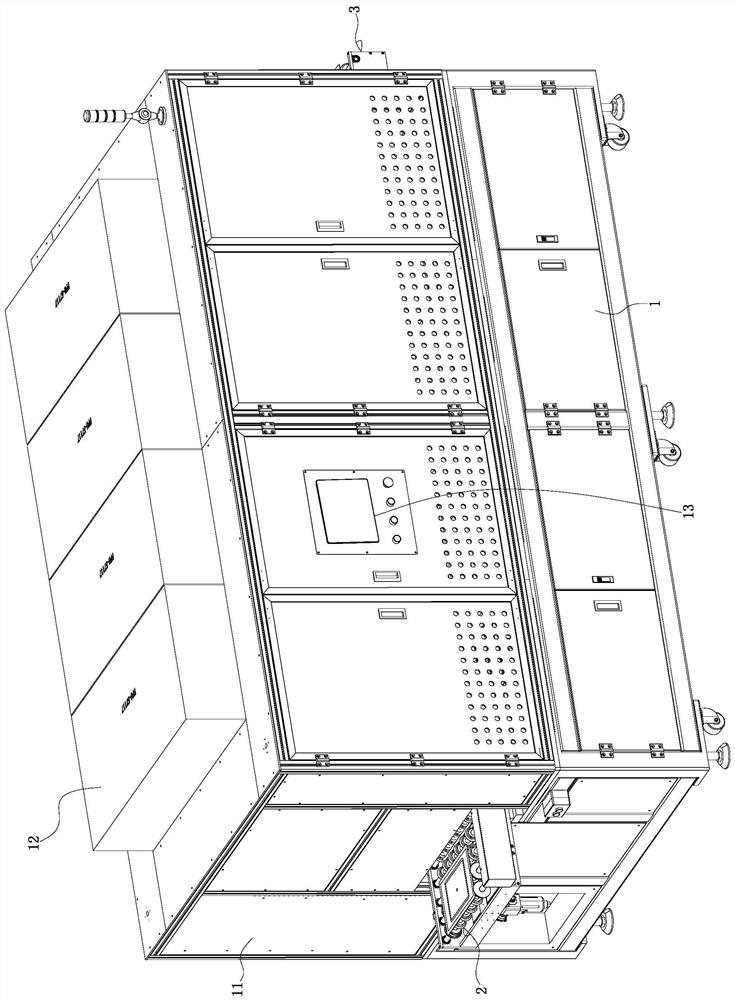

[0032] See Figure 1-11 Shown is a vehicle-mounted glass automatic surface oiling machine, which includes: a machine base 1, a feeding device 2, a feeding device 3, a wiping table 4, a handling device 5 and a wiping device 6.

[0033] Cleansing oil means to wipe off the oil stains, fingerprints, white spots and other stains left on the glass to maintain the smoothness of the glass.

[0034] The machine base 1 is provided with a casing 11 for sealing, and the casing 11 covers the feeding device 2, the unloading device 3, the wiping workbench 4, the handling device 5 and the wiping device 6, and the upper The front end of the material device 2 protrudes outside the casing 11, the rear end of the unloading device 3 protrudes outside the casing 11, and the upper end of the casing 11 is provided with an air cleaning device 12, and the air cleaning devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com