Integrated small container type emulsion explosive production line

A container-type, emulsion explosive technology, which is applied in the direction of explosives, explosive composite components, explosive processing equipment, etc., can solve the problems of modular integration, inability to produce production lines, and rapid preparation of emulsion explosive matrix, so as to improve reaction efficiency and material reaction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

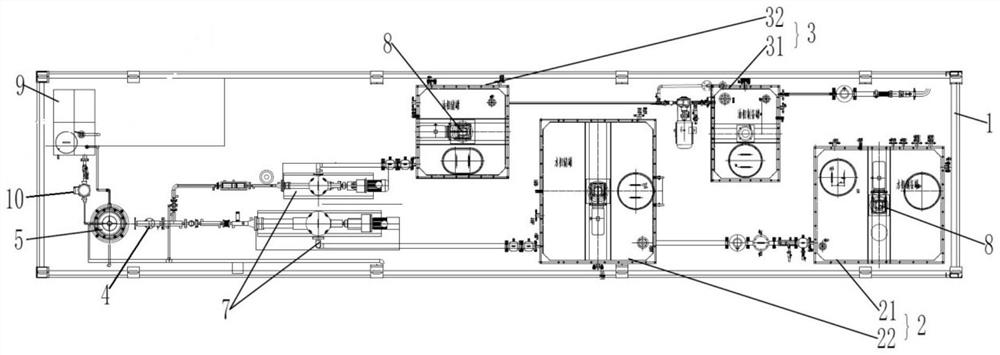

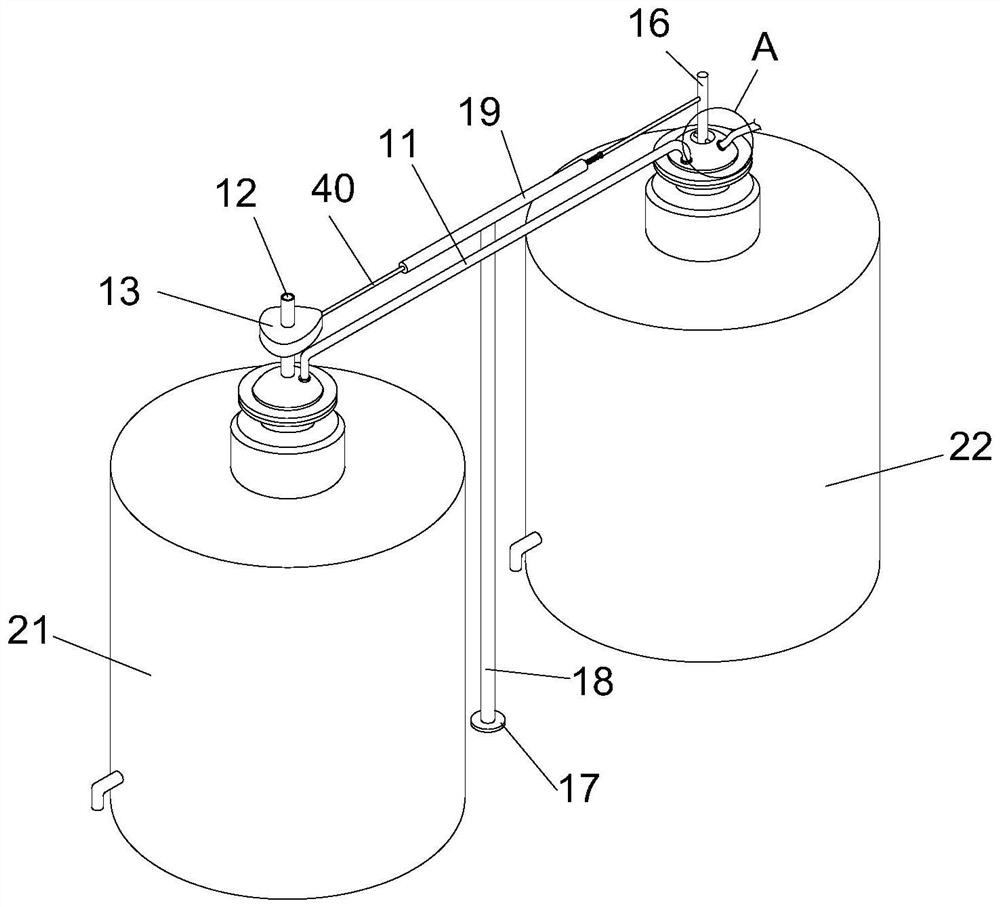

[0031] Embodiment: a kind of integrated small container type emulsion explosive production line, such as Figure 1-Figure 4 As shown, the container body 1 is included, and the inside of the container body 1 is respectively provided with a water phase mechanism 2, an oil phase mechanism 3, a static mixer 4 and an emulsifier 5, and the water phase mechanism 2 and the oil phase mechanism 3 are respectively communicated with each other. To the static mixer 4, the static mixer 4 communicates with the emulsifier 5, the water phase mechanism 2 and the oil phase mechanism 3 are arranged alternately, and the static mixer 4 is located between the emulsifier 5 and the oil phase mechanism 3 location;

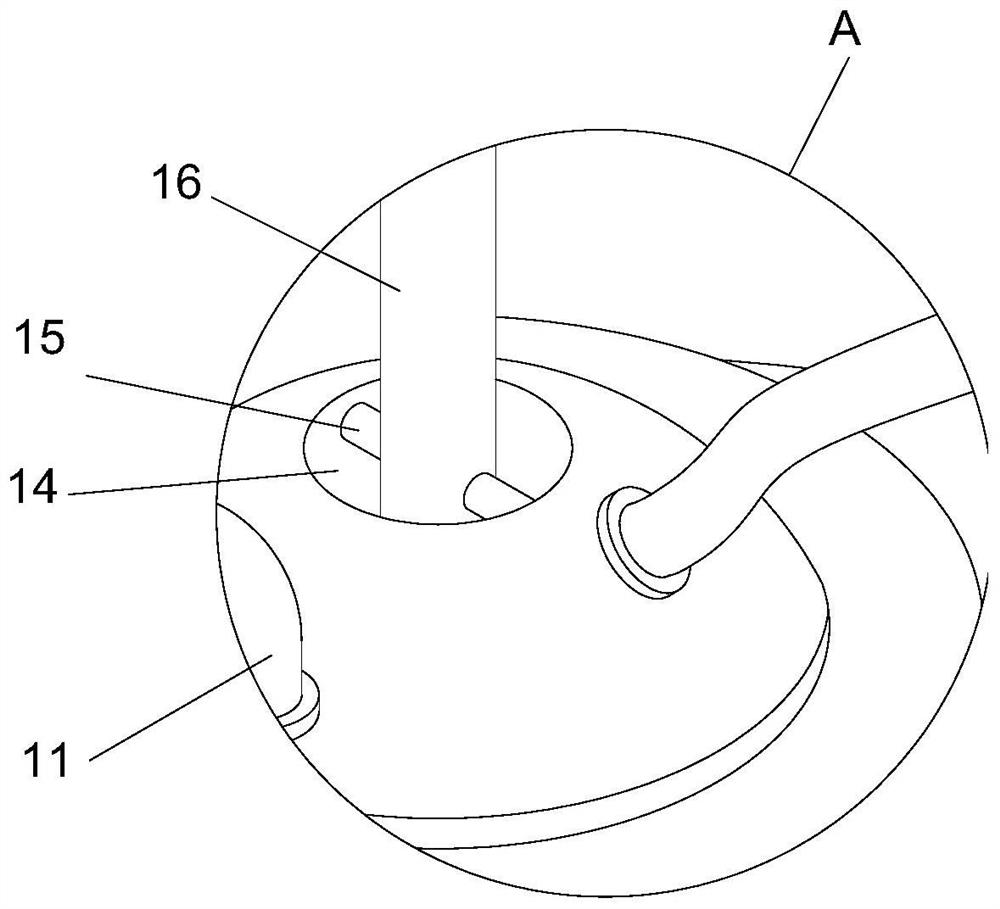

[0032]The water phase mechanism 2 includes a water phase preparation tank 21 and a water phase storage tank 22, the water phase preparation tank 21 and the water phase storage tank 22 are fixedly connected and communicated with each other through a connecting pipe 11, and the water phase st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com