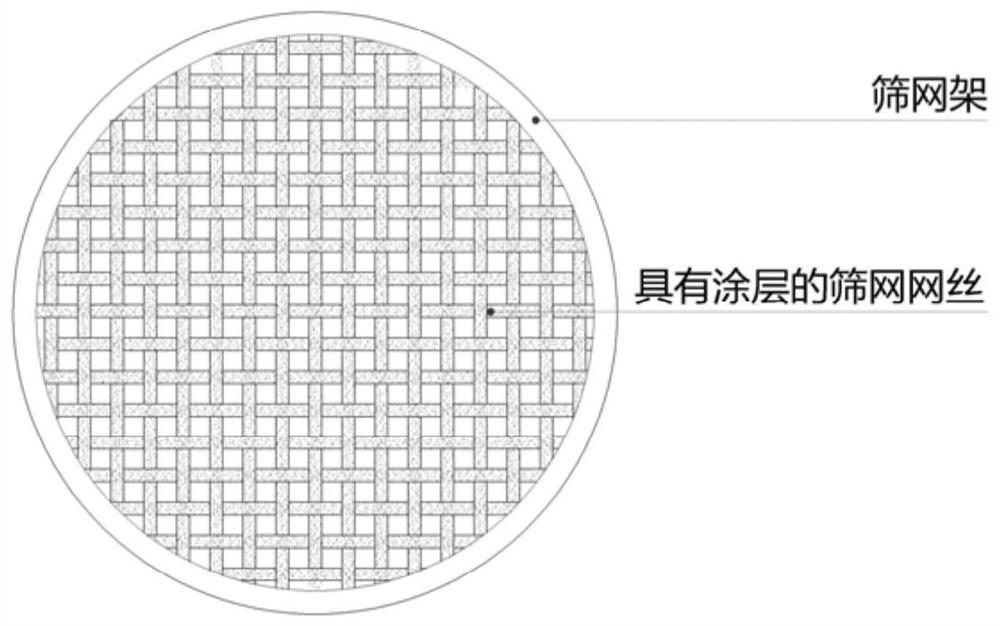

Coating composition, lithium battery ternary positive electrode material sieving screen mesh and preparation method of lithium battery ternary positive electrode material sieving screen mesh

A technology of coating composition and positive electrode material, which can be applied to coatings, chemical instruments and methods, sieves, etc., can solve problems such as inability to effectively resist alkaline corrosion, improve retention rate and service life of sieves, and reduce magnetic properties. Foreign matter content, effect of reducing the risk of breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

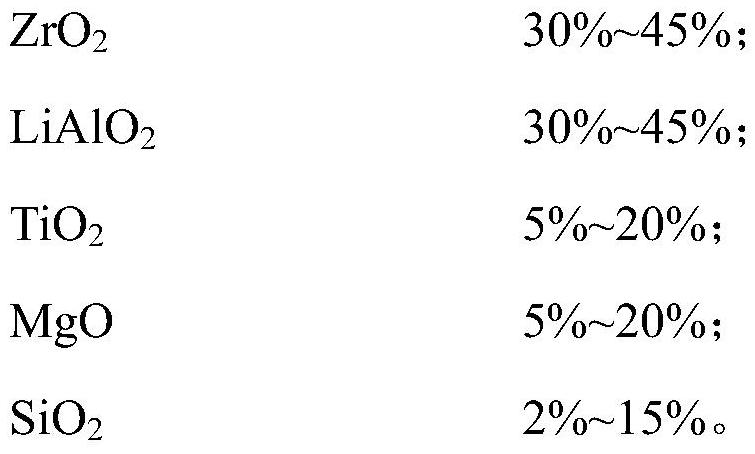

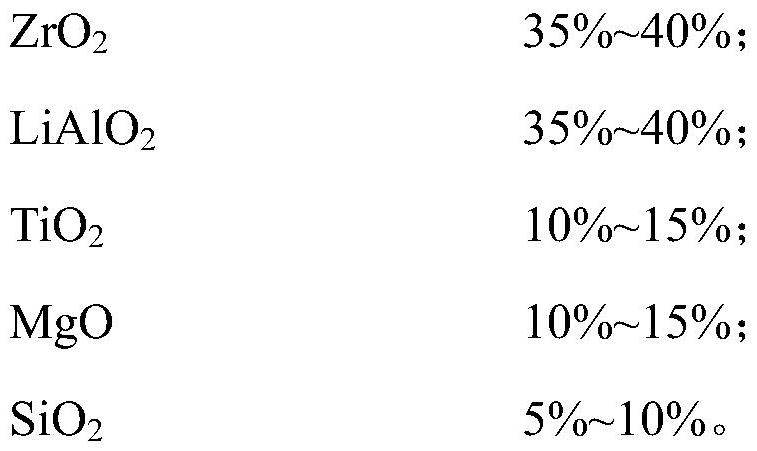

[0036] A coating composition, by mass percentage, the coating comprises the following components: ZrO 2 40%; LiAlO 2 35%;TiO 2 10%; MgO 10%; SiO 2 5%.

[0037] The steps of preparing the sieve screen of the lithium battery ternary positive electrode material using the coating composition of the above components are as follows:

[0038] S1. Weigh each component according to the mass percentage, mix and grind to obtain the powder coating raw material whose particle size is nanoscale;

[0039] S2. Spray the prepared spraying material evenly on the front and back sides of the screen wire edge by the oxygen-ethylene flame spraying method, covering the original screen wire edge, the spraying temperature is 1350°C, and the spray coating thickness is 30nm;

[0040] S3. Put the sprayed screen into a box-type furnace for sintering with the sagger as the bottom bracket, the sintering temperature is 750°C, and the sintering time is 3 hours. After sintering out of the box, test the ...

Embodiment 2

[0042] Different from Example 1, by mass percentage, the coating described in this example includes the following components: ZrO 2 35%; LiAlO 2 40%;TiO 2 10%; MgO 10%; SiO 2 5%.

Embodiment 3

[0044] Different from Example 1, by mass percentage, the coating described in this example includes the following components: ZrO 2 35%; LiAlO 2 35%;TiO 2 10%; MgO 10%; SiO 2 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com