Water supply and drainage equipment for hydraulic engineering construction

A water conservancy project, water supply and drainage technology, applied in the direction of water conservancy engineering equipment, water conservancy engineering, mechanical equipment, etc., can solve the problems of drainage tank congestion, drainage tank flow reduction, etc., and achieve the effect of safe discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

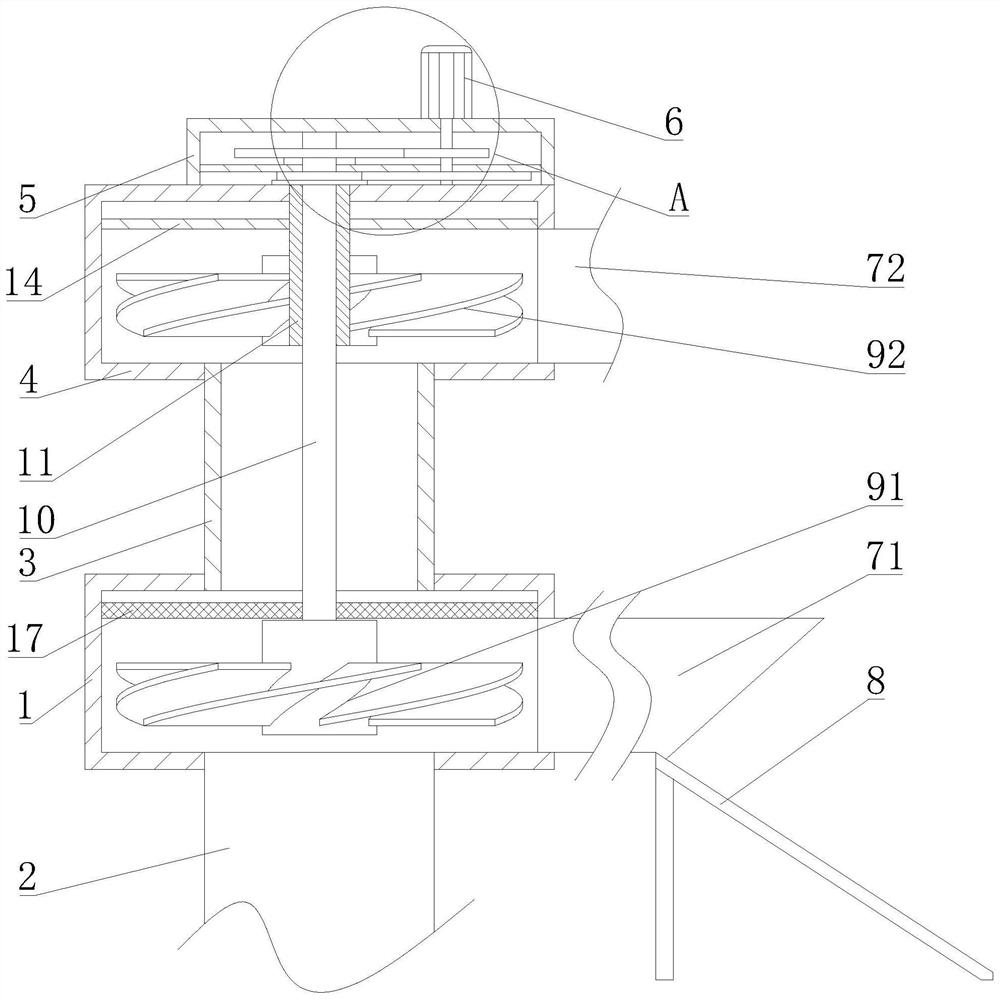

[0021] Such as Figure 1-3 As shown, a kind of water supply and drainage equipment for water conservancy construction proposed by the present invention includes a water suction frame 1, water pipe 2, connecting pipe 3, b water suction frame 4, a drain pipe 71, b drain pipe 72, a impeller 91, b Impeller 92, a rotating column 10, b rotating column 11 and filter screen 17;

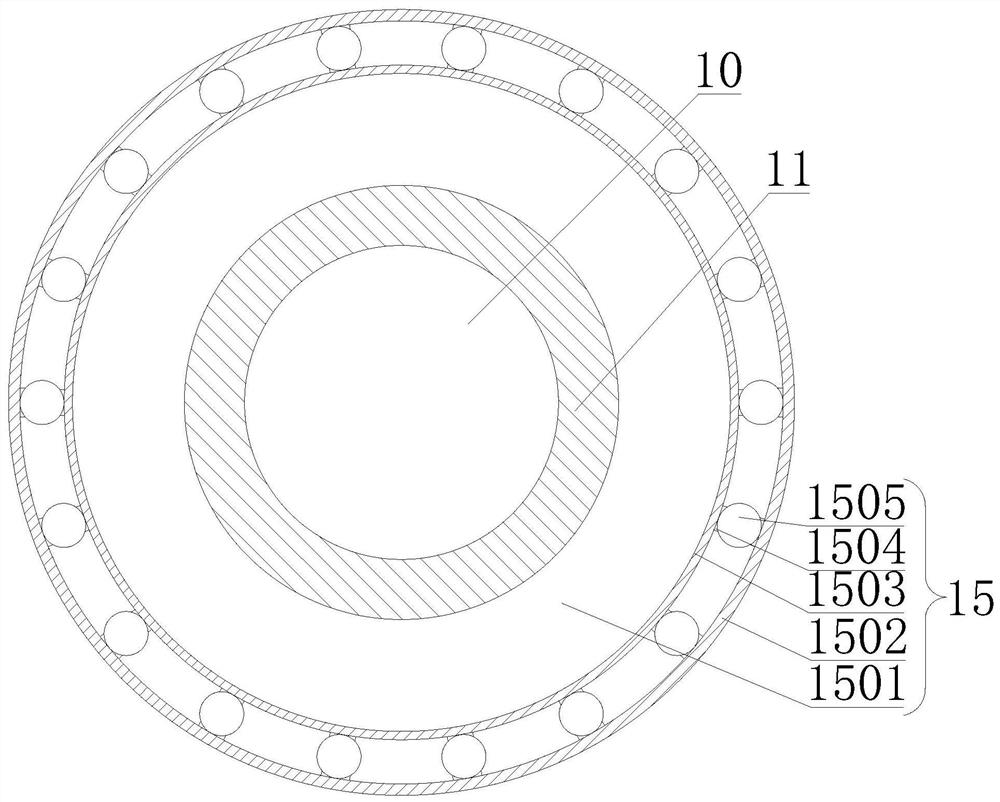

[0022] The two ends of the connecting pipe 3 communicate with the water absorption frame a and the water absorption frame b respectively, and the b water absorption frame 4 is located above the a water absorption frame 1; the water pipe 2 is arranged at the lower end of the a water absorption frame 1; On the frame 1, the b drain pipe 72 is arranged on the b water absorption frame 4; the b rotating column 11 is arranged on the b water absorbing frame 4, and the b impeller 92 is arranged on the b rotating column 11; the b rotating column 11 is a hollow circular tubular structure; a The rotation column 10 is in...

Embodiment 2

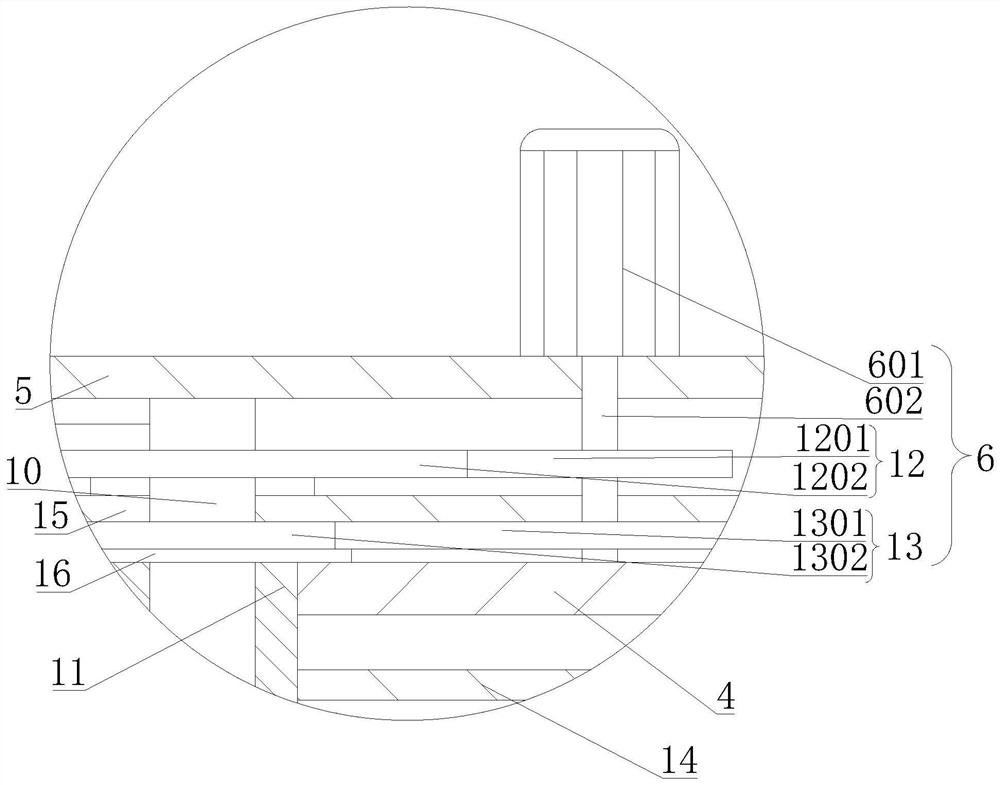

[0025] Such as Figure 1-3 As shown, the present invention proposes a water supply and drainage equipment for water conservancy construction. Compared with Embodiment 1, the driving mechanism 6 in this embodiment includes a driving motor 601, a rotating shaft 602, a deceleration transmission mechanism 12 and a speed-up transmission mechanism 13 ; The b water-absorbing frame 4 is provided with mounting frame 5; Driving motor 601 is arranged on mounting frame 5, and the output end of driving motor 601 is connected with rotating shaft 602; Above; the output end of the deceleration transmission mechanism 12 is connected to the a rotating column 10; the output end of the speed increasing transmission mechanism 13 is connected to the b rotating column 11.

[0026] In this embodiment, the driving motor 601 drives the rotating shaft 602 to rotate, so that the rotating speed of the rotating shaft 602 is constant, the a rotating column 10 is driven to rotate through the deceleration tra...

Embodiment 3

[0028] Such as Figure 1-3 As shown, the present invention proposes a water supply and drainage equipment for water conservancy construction. Compared with Embodiment 1 or Embodiment 2, the reduction transmission mechanism 12 in this embodiment includes a driving gear 1201 and a driven gear 1202; The gear 1201 is arranged on the rotating shaft 602; the a driven gear 1202 is arranged on the a rotating column 10, and the a driving gear 1201 is engaged with the a driven gear 1202; the number of teeth of the a driving gear 1201 is smaller than that of the a driven gear 1202. Speed-up transmission mechanism 13 comprises b driving gear 1301 and b driven gear 1302; b driving gear 1301 is arranged on the rotating shaft 602, b driven gear 1302 is arranged on b rotating column 11; b driving gear 1301 and b driven gear 1302 meshing connection; the number of teeth of a driving gear 1201 is equal to the number of teeth of b driven gear 1302; the number of teeth of a driven gear 1202 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com