Full-automatic lying type baking line

A baking line, fully automatic technology, applied in the field of fully automatic flat-laying baking line, can solve the problem of multi-time, etc., and achieve the effect of improving work efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

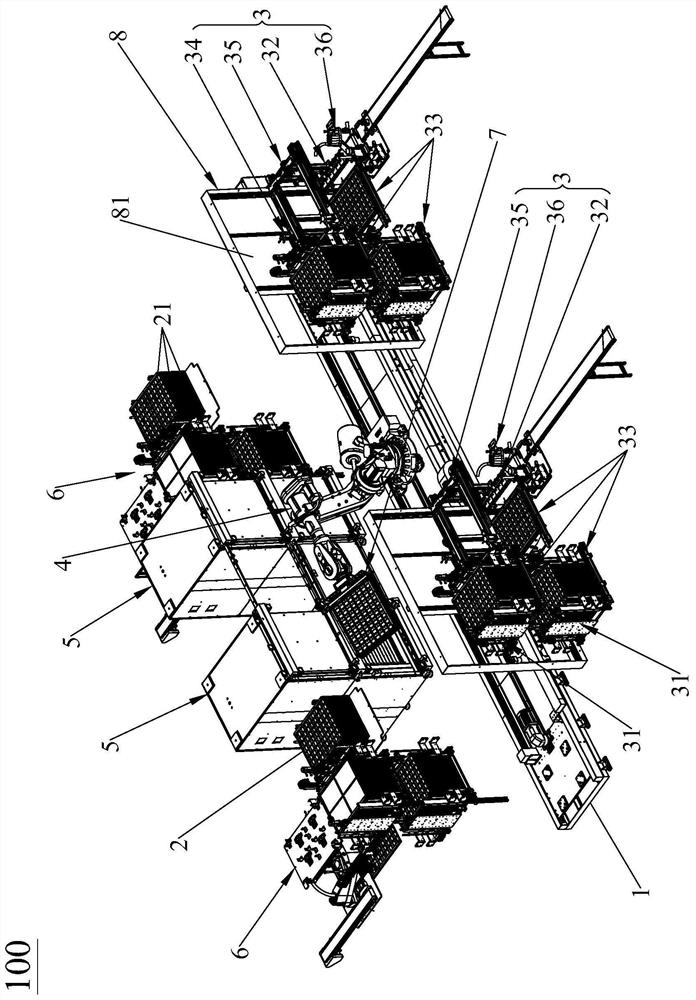

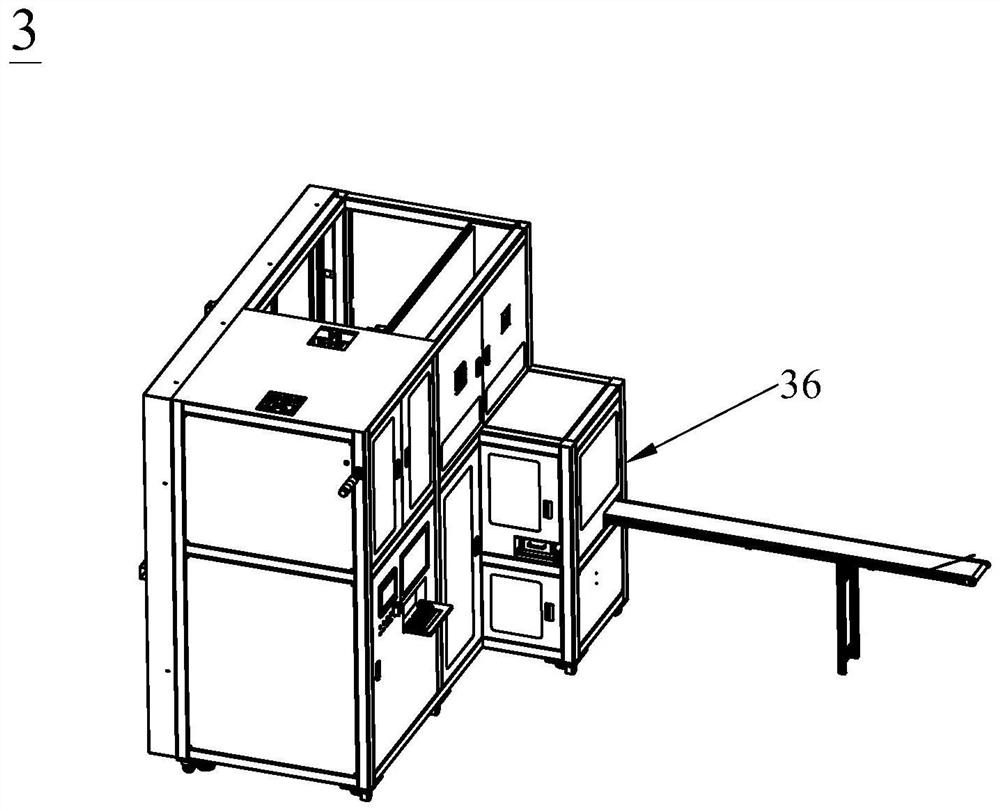

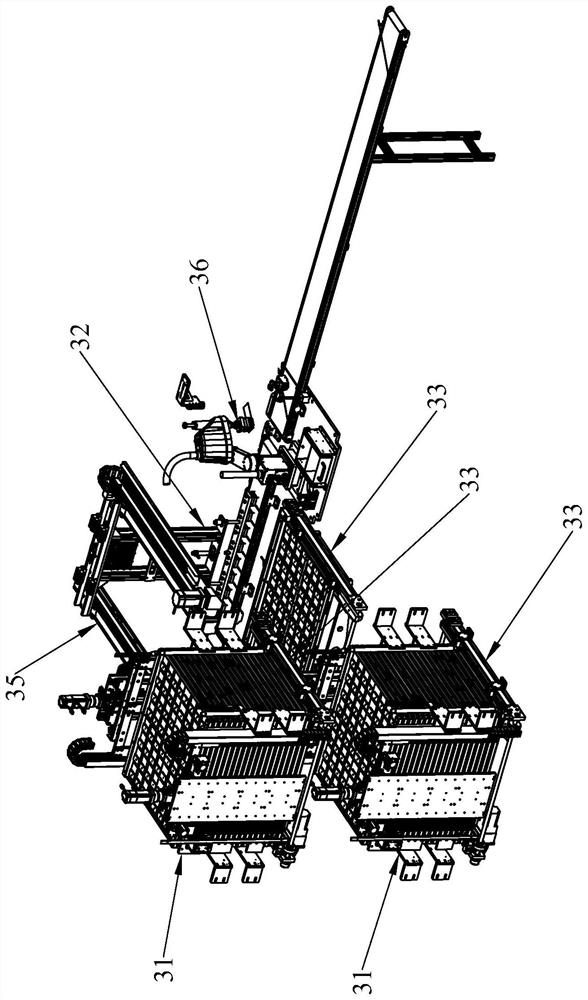

[0030] see figure 1 , the fully automatic flat-laying baking line 100 of the present invention includes a ground rail 1, a number of trays 2 for carrying batteries, a loader 3 for fully loading batteries on the trays 2 and stacking the trays 2, and The manipulator 4 for picking up and transferring the tray 2, the oven 5 for baking the cells, and the unloading machine 6 for stacking the baked trays 2 and unloading the cells in the tray 2. The ground rail 1 is fixed on the ground, the ground rail 1 is arranged along a horizontal direction, the manipulator 4 is arranged on the ground rail 1 slidingly along the horizontal direction, and the feeder 3 is arranged on one side of the ground rail 1 along the width direction , the oven and the unloading machine 6 are loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com