Modularized heat dissipation device of power battery pack

A power battery pack and cooling device technology, applied in the field of power battery cooling, to achieve high heat dissipation efficiency and maximize energy per unit volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

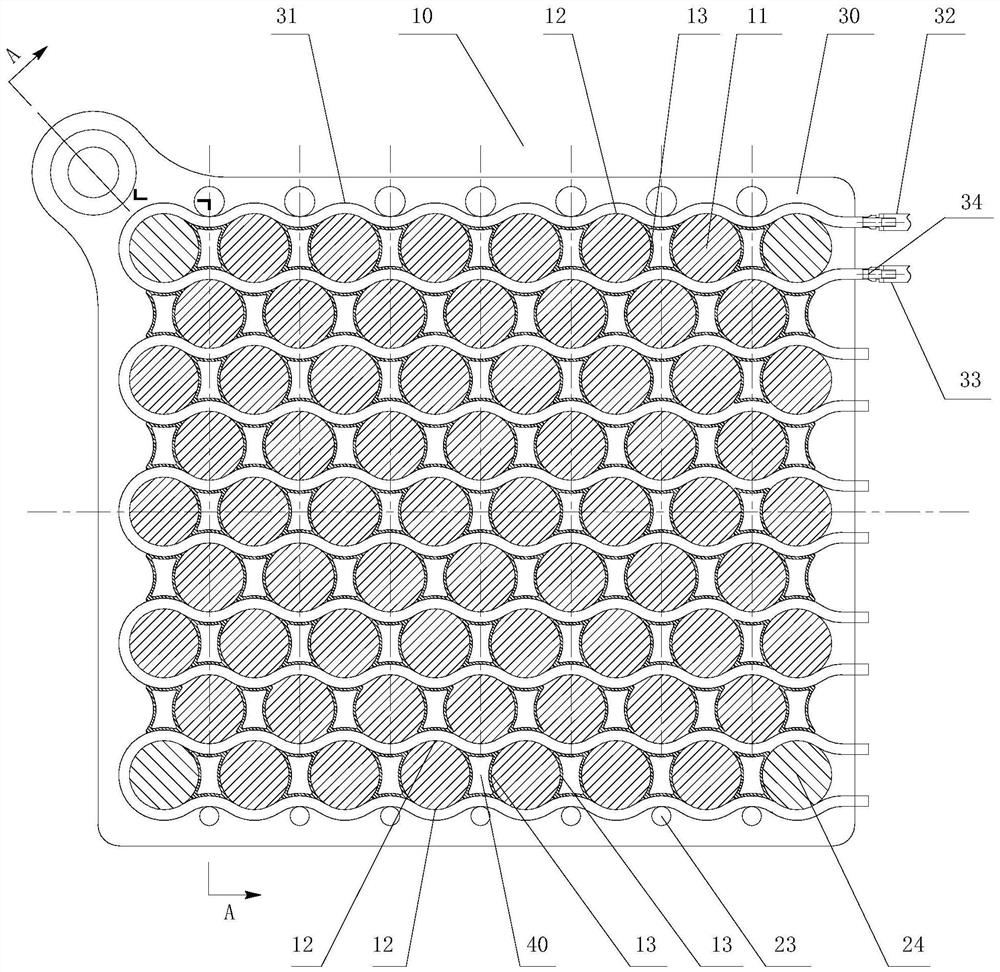

[0047] Such as Figure 1-7 As shown, a modular cooling device for a power battery pack, including

[0048] A battery module 10, the battery module 10 includes a plurality of cylindrical battery cells 11, the axis of the plurality of battery cells 11 is arranged parallel to the height direction of the battery module and forms at least two layers with a certain row spacing and column spacing array arrangement; a plurality of said battery modules 10 arrays are fixed in the power battery pack housing 1;

[0049] The clamping mechanism 20, the clamping mechanism 20 is used to maintain the array arrangement of the battery modules and realize the electrical connection of the battery cells 11;

[0050] The first heat dissipation 30, the first heat dissipation 30 includes a plurality of heat dissipation strips 31, the heat dissipation strips 31 are continuously extended between the rows of the battery module 10, and are used to take away two of the battery cells 11. the heat of the o...

Embodiment 2

[0070] The axes of the battery cells are arranged perpendicular to the height direction of the battery module and arranged in a multi-layer array. The second integral liquid feeding chamber for heat dissipation is replaced by parallel multi-row liquid feeding chambers. The other structures are the same as in Example 1.

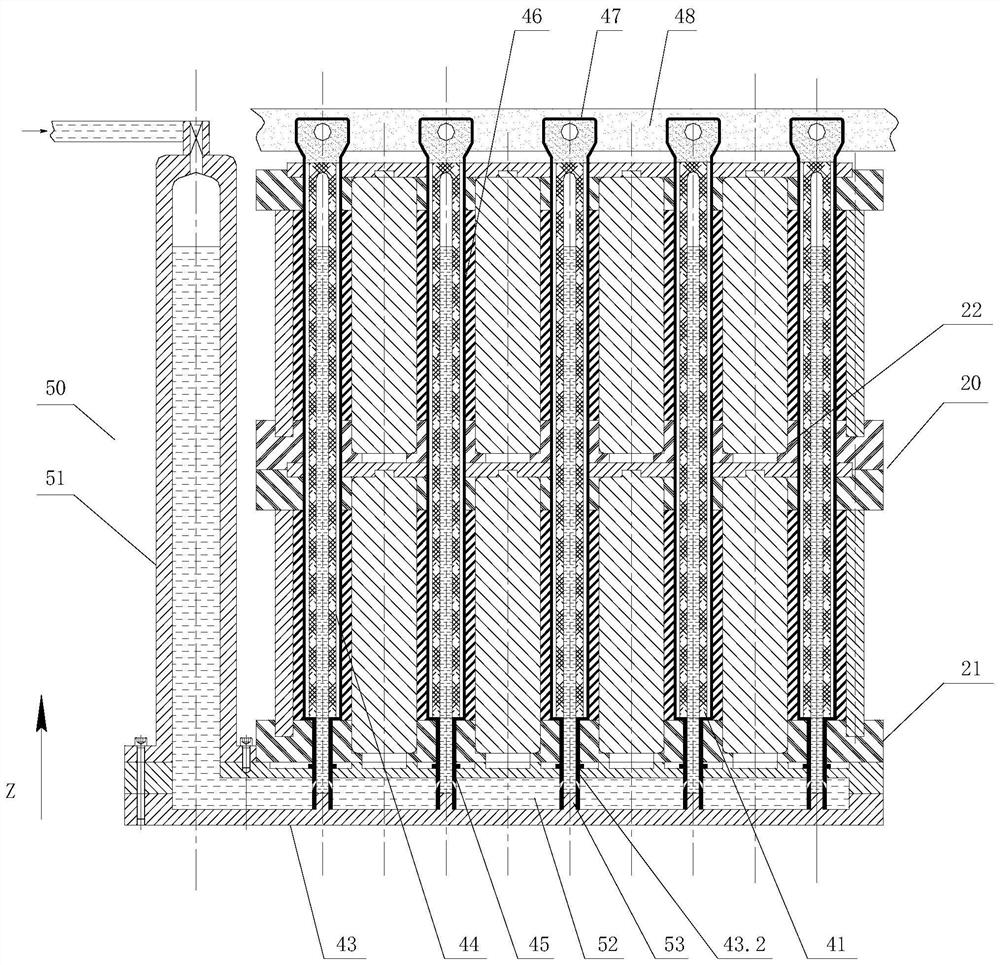

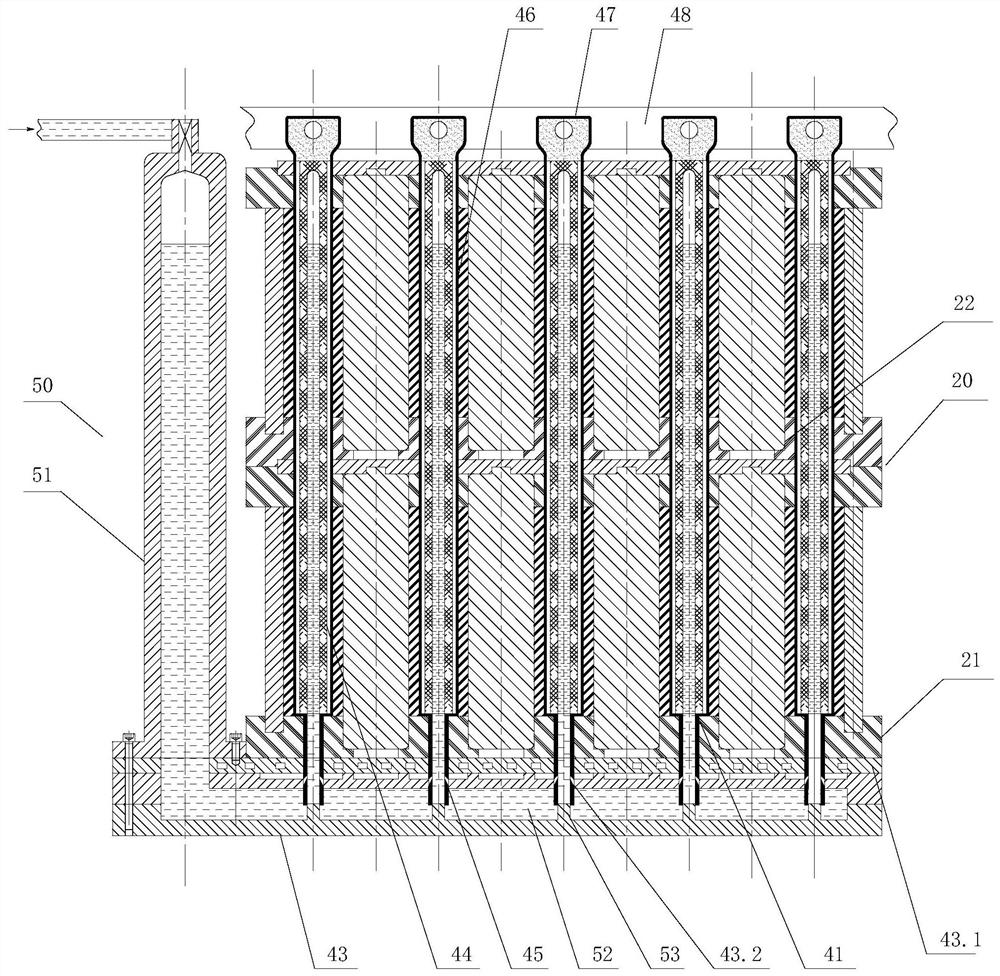

[0071] Such as Figure 8 , shown in 9, a modular cooling device for a power battery pack, including

[0072] A battery module 10, the battery module 10 includes a plurality of cylindrical battery cells 11, the axes of the plurality of battery cells 11 are arranged perpendicular to the height direction of the battery module and form at least three layers with a certain row spacing and column spacing Arranged in an array; a plurality of battery modules 10 are fixed in an array in the power battery pack casing 1;

[0073] When the axis of the battery cells 11 is placed horizontally, the array is arranged in at least 3 layers, the height of the battery cells in t...

Embodiment 3

[0076] The first heat dissipation is changed from liquid cooling to loop heat pipes, and other structures are the same as those in Embodiments 1 and 2.

[0077] Such as Figure 10 , 11 As shown, a modular heat dissipation device for a power battery pack, the first heat dissipation 30 is a loop heat pipe, and the heat dissipation strip 31 is used as an evaporation part to communicate with the condensation part 42 through a steam pipe and a liquid return pipe. The inner cavity of the heat dissipation strip 31 is provided with a liquid-absorbing core 36 and a metal foam 37. When the axes of the battery cells 11 are arranged in an array parallel to the height direction of the battery module, the liquid-absorbing core strip and the foam metal strip are within the width of the heat dissipation strip. The direction is closely arranged in the inner cavity up and down, and both of them are arranged in the inner cavity extending along the entire length direction of the heat dissipation s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com