Rotor assembling method, and control device for rotor assembly apparatus

An assembly method and a technology for assembling devices, which are applied in the direction of electromechanical devices, manufacturing stator/rotor bodies, electric components, etc., can solve the problems of low performance of rotating electrical machines, achieve the purpose of suppressing the reduction of insertability, improving performance, and reducing positional deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

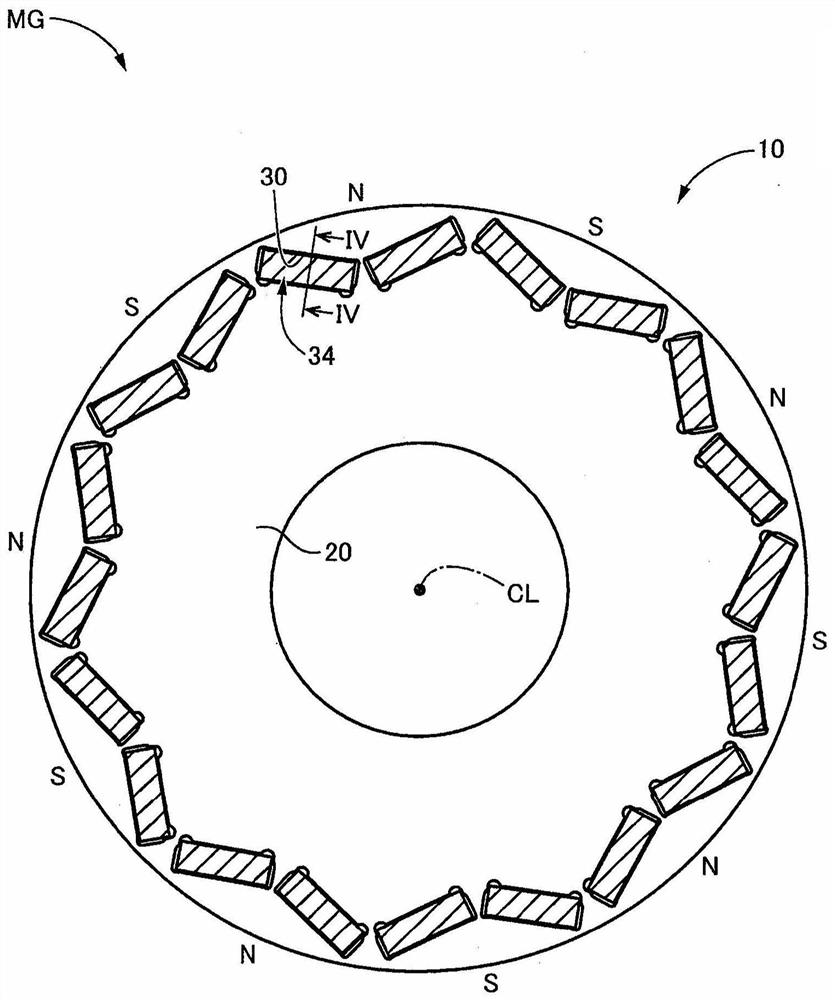

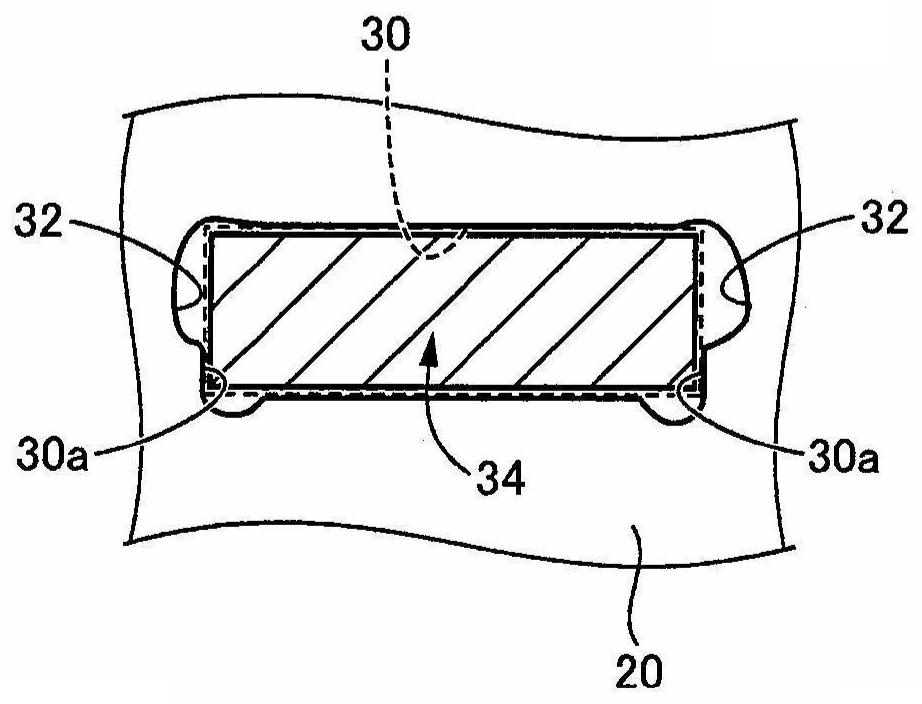

[0059] figure 1 It is a cross-sectional view illustrating a schematic structure of a rotor 10 to which the present invention is applied. figure 1 is a cross-sectional view of the rotor 10 perpendicular to the axis CL. Hereinafter, the "direction parallel to the axis line CL" is simply referred to as "the axis line CL direction".

[0060] The rotor 10 is disposed, for example, on a vehicle rotating electrical machine MG mounted on a hybrid vehicle or an electric vehicle, which is a drive source for traveling of the vehicle. The vehicle rotating electrical machine MG is a rotating electrical machine having a function as an electric motor (motor) and a function as a generator (generator), that is, a so-called motor generator. The vehicle rotating electric machine MG is a magnet-embedded rotating electric machine, and includes a stator having an unillustrated field winding, and a rotor 10 in which permanent magnets 34 are embedded or inserted.

[0061] The rotor 10 has a cylind...

Embodiment 2

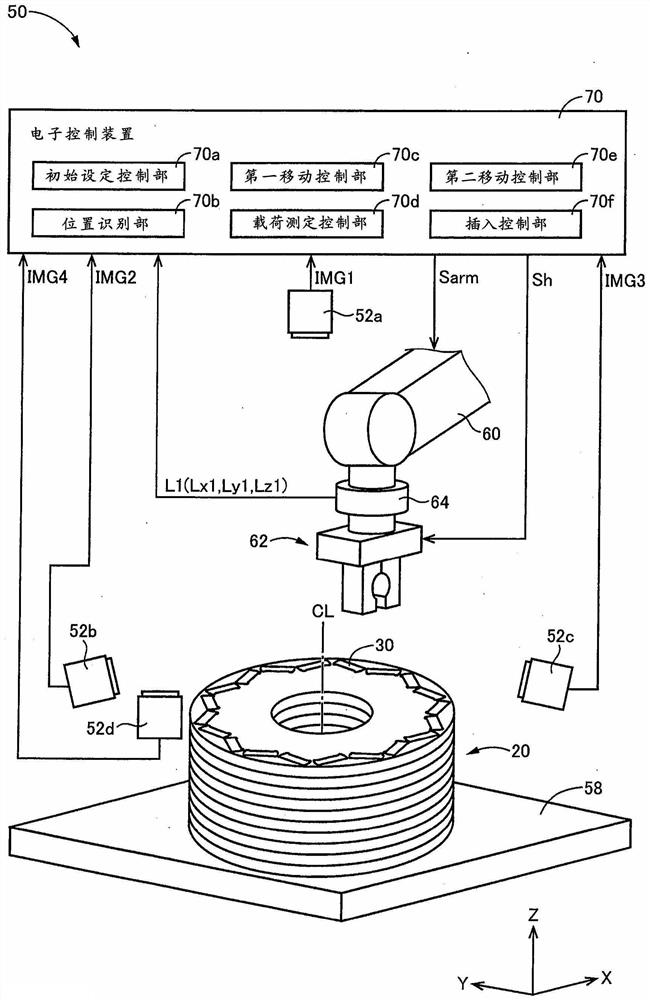

[0114] Figure 6 It is a figure explaining the schematic structure of the rotor assembly apparatus 150 used for the assembly method of the rotor 10 in Example 2 of this invention, and is a figure explaining the main part of the control function used for various control in the rotor assembly apparatus 150. . The structure of the rotor assembly device 150 is substantially the same as that of the rotor assembly device 50 in the first embodiment described above, but the main difference is that a fixed table 158 and a load sensor 164 are provided instead of the fixed table 58 and the load sensor 64 . Therefore, in the present embodiment, the description will focus on the parts that are different from the above-mentioned first embodiment, and the same reference numerals will be assigned to the parts that are substantially common in function with the above-mentioned first embodiment, and the description will be omitted as appropriate. .

[0115] The fixing table 158 fixes and holds...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap