Double-station cigar-shaped tea leaf compression molding mold

A compression molding, cigar-shaped technology, which is applied in the field of double-station cigar-shaped tea compression molding molds, can solve problems such as low work efficiency, and achieve the effects of high practicability, improved time utilization rate, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

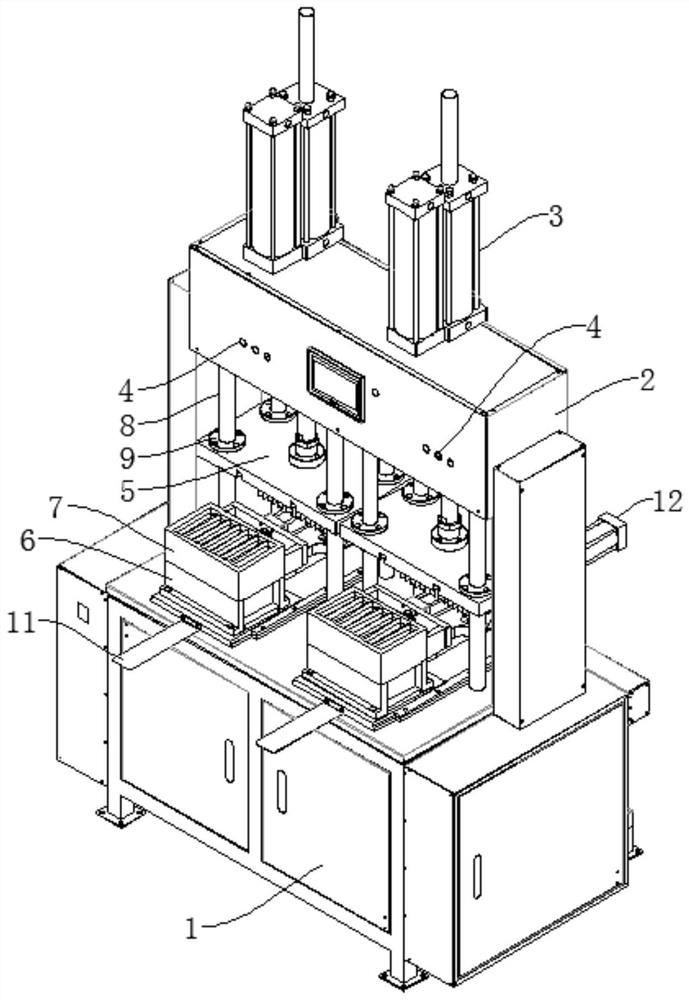

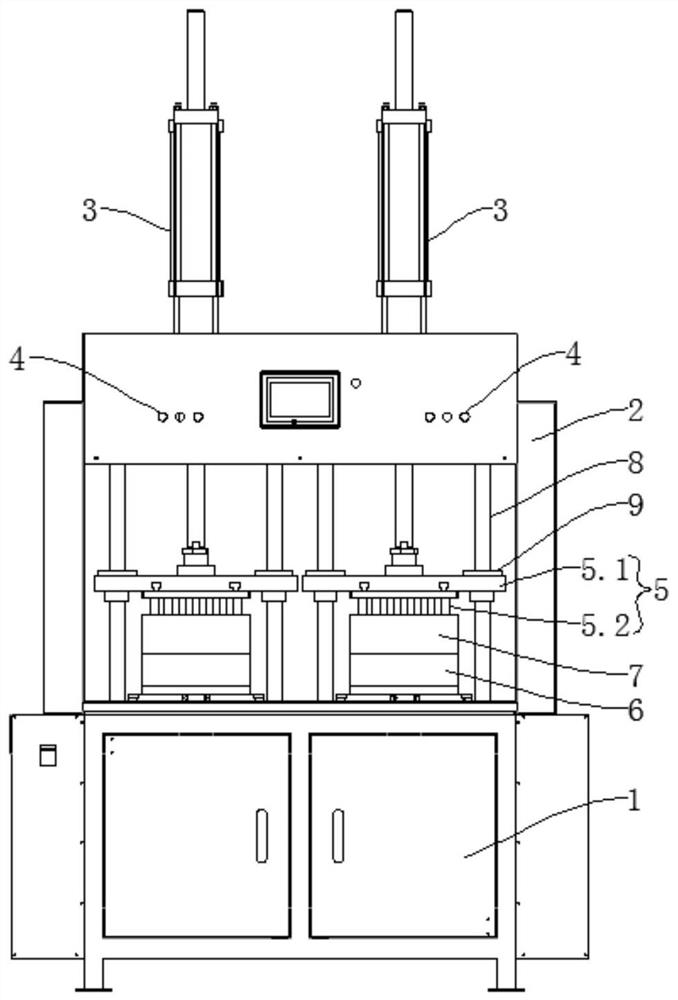

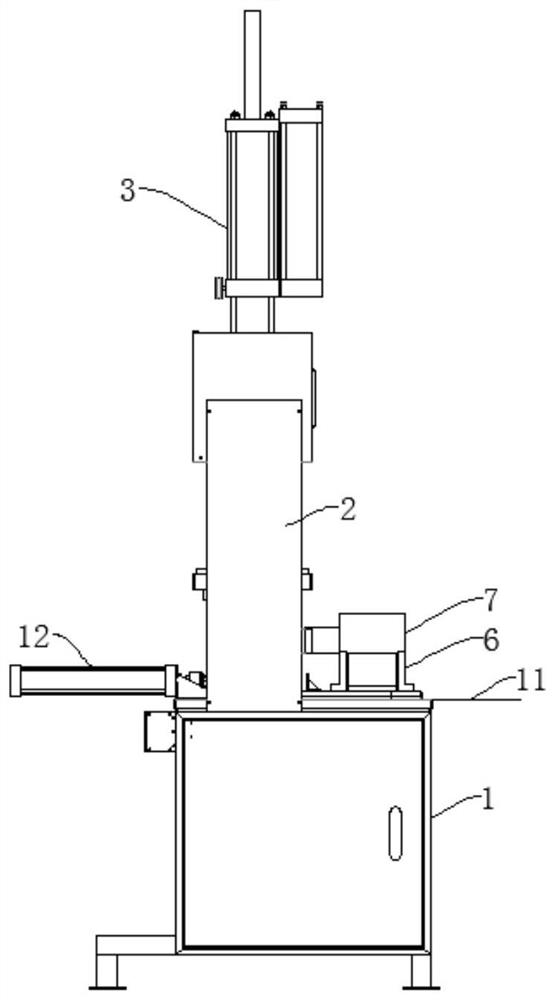

[0039] like Figure 1-5 As shown, the present embodiment provides a dual station cigar tea press molding mold including the electric cabinet 1, and the electrical cabinet is provided with a support frame 2. The top of the support frame 2 is provided with two sets of first telescopic mechanism 3, support frame. 2 The two sets of control buttons 4 are provided, and the two sets of control buttons 4 are electrically connected to the corresponding first telescopic mechanism 3, and the first telescoping mechanism 3 is connected to the lower mold 5, and the electrical cabinet 1 is provided with two groups. The lower mold 6 is pressed, and the upper mold opening 6 is provided, and the molded medium mold 7 is pressed, and the molded medium mold 7, the molding medium 7, and the press mold 6 can be combined together to form a mold assembly, and the mold assembly can form a cigar tea. Cavity 10.

[0040]In the present embodiment, the corresponding first telescoping mechanism 3 can be independ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com