Multi-station multi-injection molding thick-wall lens injection mold

A technology of multiple injection molding and injection molding, which is applied to household appliances, other household appliances, optical components, etc., can solve problems such as affecting work efficiency, complex molds, and lack of self-locking function, so as to improve injection molding efficiency and improve the scope of application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] Such as Figure 1-10 Shown:

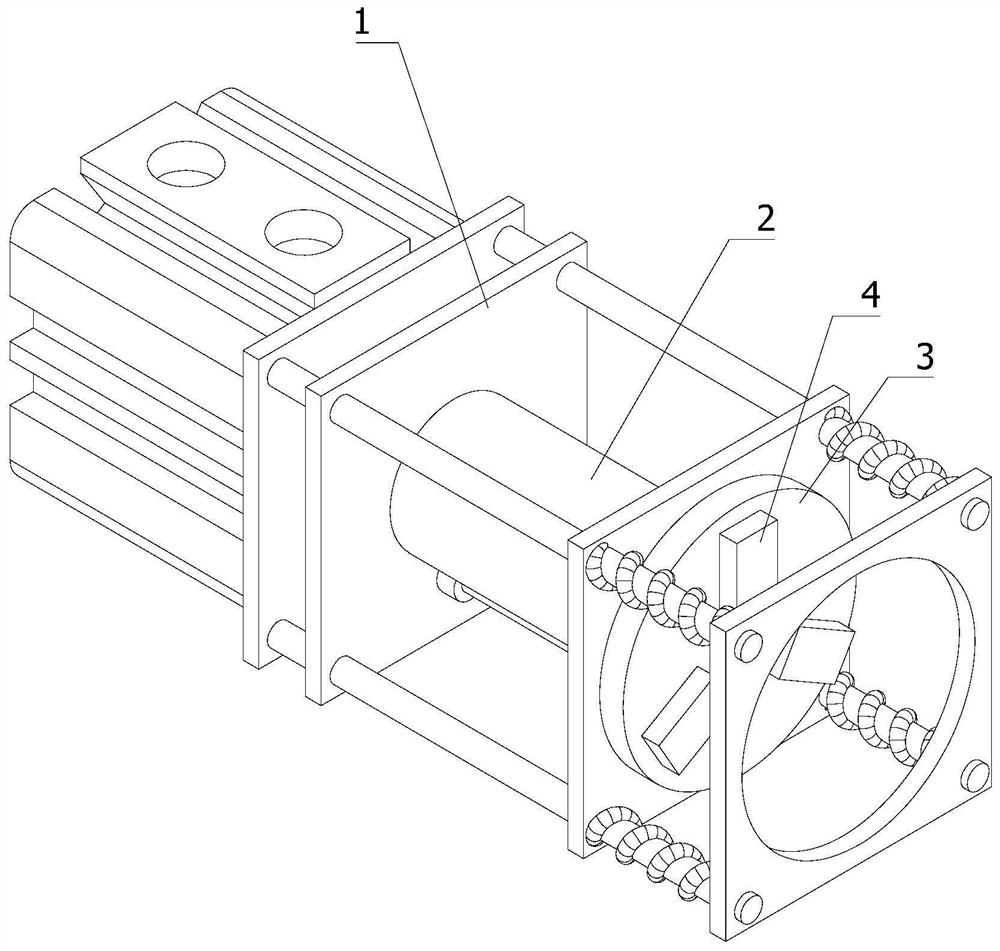

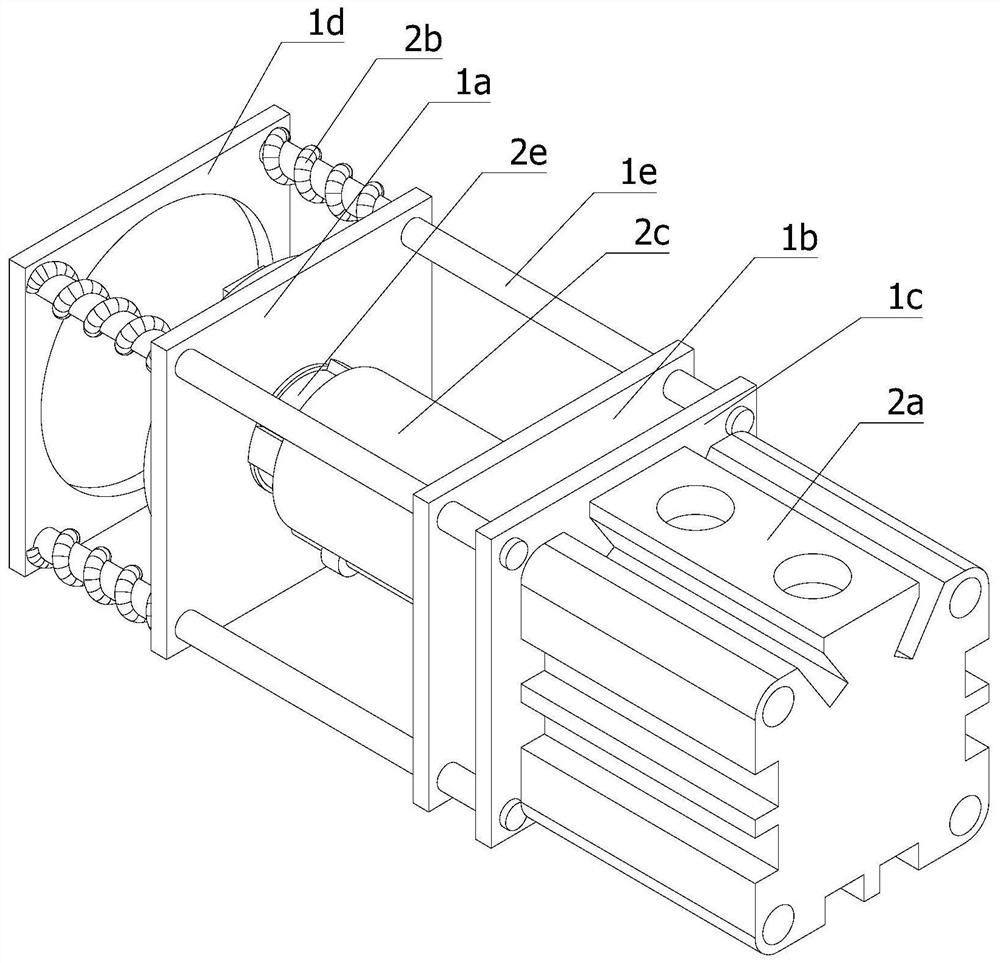

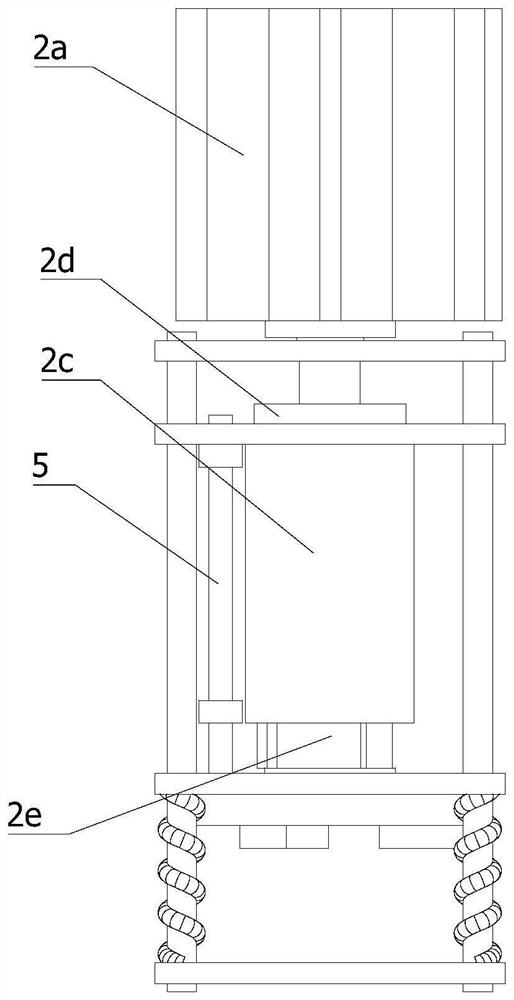

[0037]A thick-walled lens injection mold with multi-station multiple injections, including a mounting bracket 1, a rotating drive mechanism 2, a rotating platform 3 and a movable mold 4, the rotating driving mechanism 2 is installed on the mounting bracket 1, and the rotating platform 3 can rotate Set on the mounting bracket 1, the movable mold 4 includes multiple sets, and the multiple sets of movable molds 4 are annularly installed on the rotary platform 3 around the axial direction of the rotary platform 3, and the output end of the rotary drive mechanism 2 is connected to the rotary platform 3 through transmission.

[0038] Based on the above-mentioned embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com