Control device and control method for dynamically controlling utilization rate of sputtering target material

A sputtering target and dynamic control technology, which is applied in sputtering coating, metal material coating process, ion implantation plating, etc., can solve the problems of wasting time, affecting work efficiency, and complicated measurement methods, so as to improve data quality. Statistical efficiency, improving utilization efficiency, and improving the effect of control effects

Inactive Publication Date: 2022-02-01

苏州德耐纳米科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a control device and a control method for dynamically controlling the utilization rate of sputtering targets, so as to solve the problem that the existing control devices for the utilization rate of sputtering targets proposed in the above-mentioned background art have complex measurement methods and affect work efficiency. Online real-time measurement cannot be realized, which wastes time and cannot dynamically control the utilization of targets

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

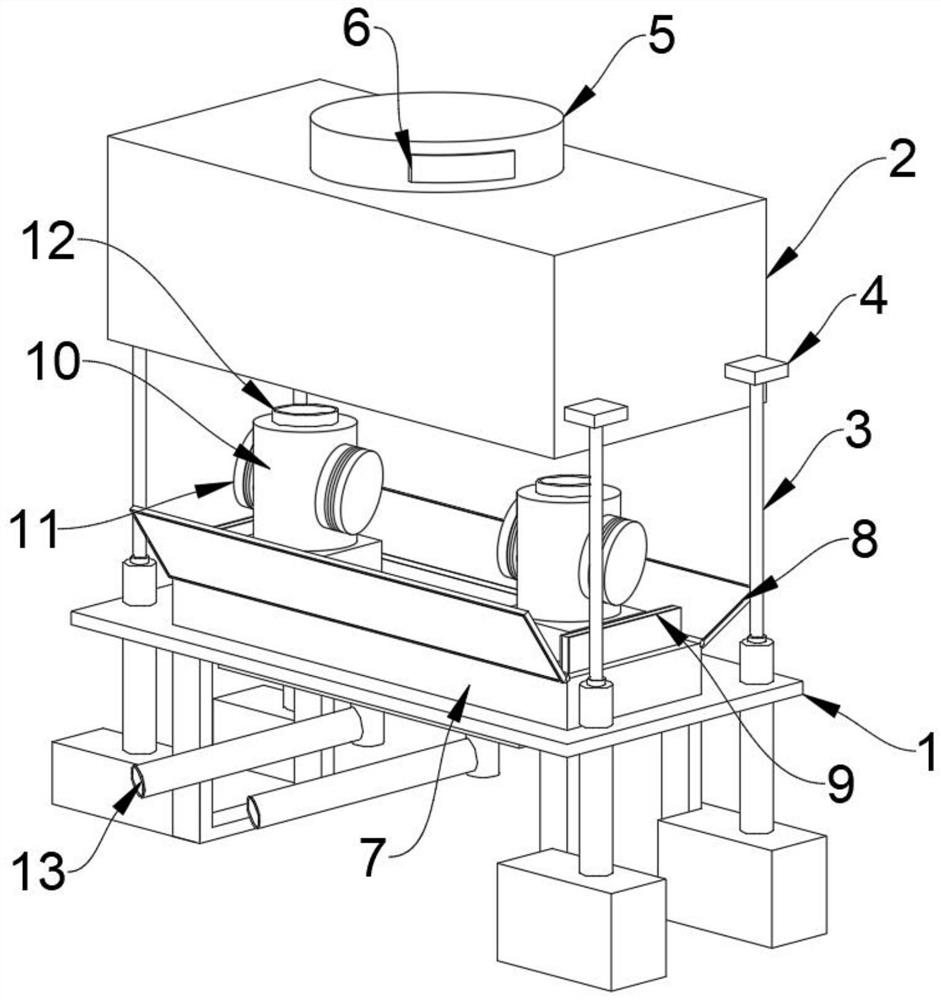

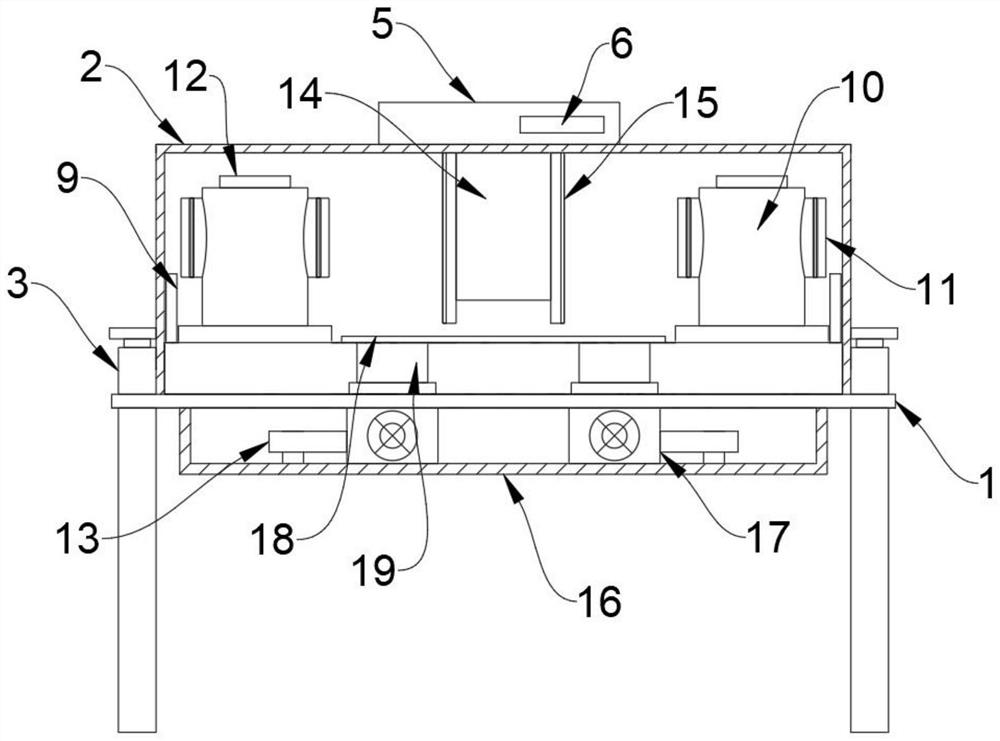

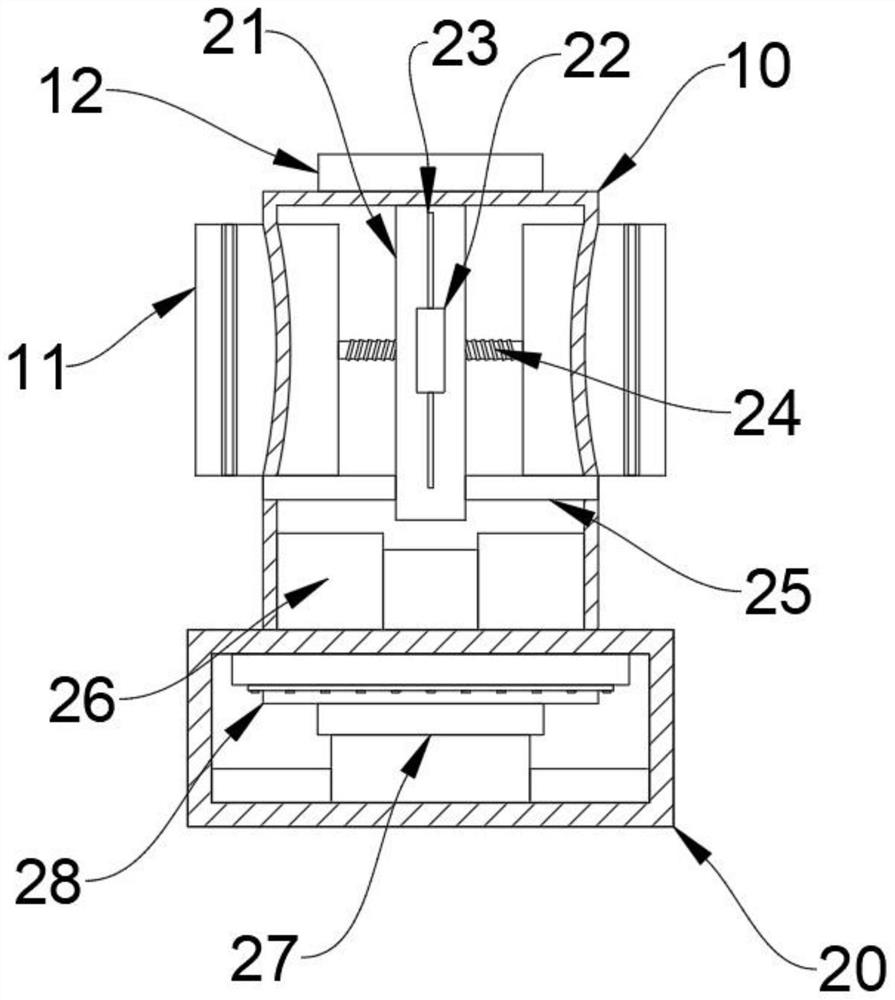

The invention discloses a control device and a control method for dynamically controlling the utilization rate of a sputtering target material, relates to the field of magnetron sputtering coating, and aims to solve the problems that in the prior art, a control device for the utilization rate of a sputtering target material is complex in measurement mode, the working efficiency is affected, online real-time measurement cannot be achieved, time is wasted, and the utilization rate of the target material cannot be dynamically controlled. A fixed seat is mounted on the upper end face of a target material sputtering workbench, lifting protection plates are mounted above the two ends of the fixed seat, movable protection plates are mounted on the front end face and the rear end face of the fixed seat, a sealing cover body is mounted above the target material sputtering workbench, and an electric box is mounted above the sealing cover body. A magnetic field generator is installed at the lower end of the electrical box, and electrode plates are installed on the two sides of the magnetic field generator. A target material base is installed above an inner fixing box, and sputtering target material bodies are installed on the two sides of the target material base.

Description

technical field [0001] The invention relates to the technical field of magnetron sputtering coating, in particular to a control device and a control method for dynamically controlling the utilization rate of a sputtering target. Background technique [0002] Magnetron sputtering coating is a new type of physical vapor coating method, which uses the electrode plate system to emit and focus electrons on the material to be plated, so that the sputtered atoms follow the principle of momentum conversion and detach with higher kinetic energy. The material flies to the substrate to deposit a film. The material to be plated is called a sputtering target. Sputtering is one of the main technologies for preparing thin film materials. It uses ions generated by ion sources to gather them in a vacuum to form a high-speed energy ion beam. When the solid surface is bombarded, kinetic energy exchange occurs between ions and solid surface atoms, so that the atoms on the solid surface leave t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C14/35C23C14/54C23C14/56

CPCC23C14/35C23C14/54C23C14/56

Inventor 范玉山张梓江

Owner 苏州德耐纳米科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com