A group pile type bridge anti-ship collision device

An anti-ship collision and bridge technology, applied in road safety devices, sheet pile walls, transportation and packaging, etc., can solve the problems of unfavorable bridge protection effect, low deformation and energy dissipation of anti-ship collision devices, and achieve good anti-collision protection effect , Improve the effect of buffering and energy dissipation, and increase the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

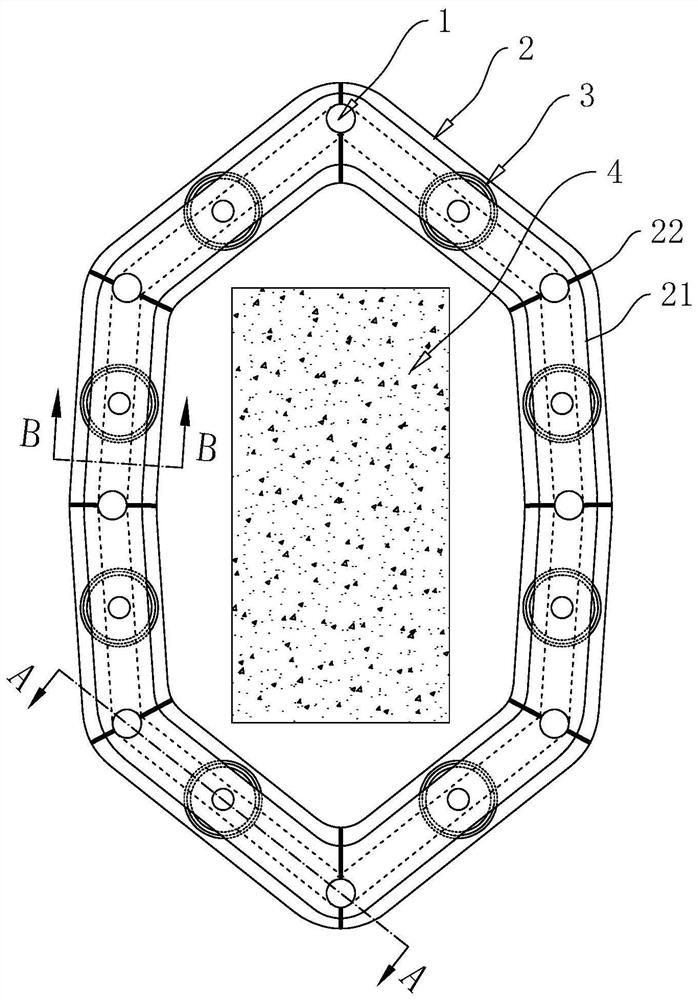

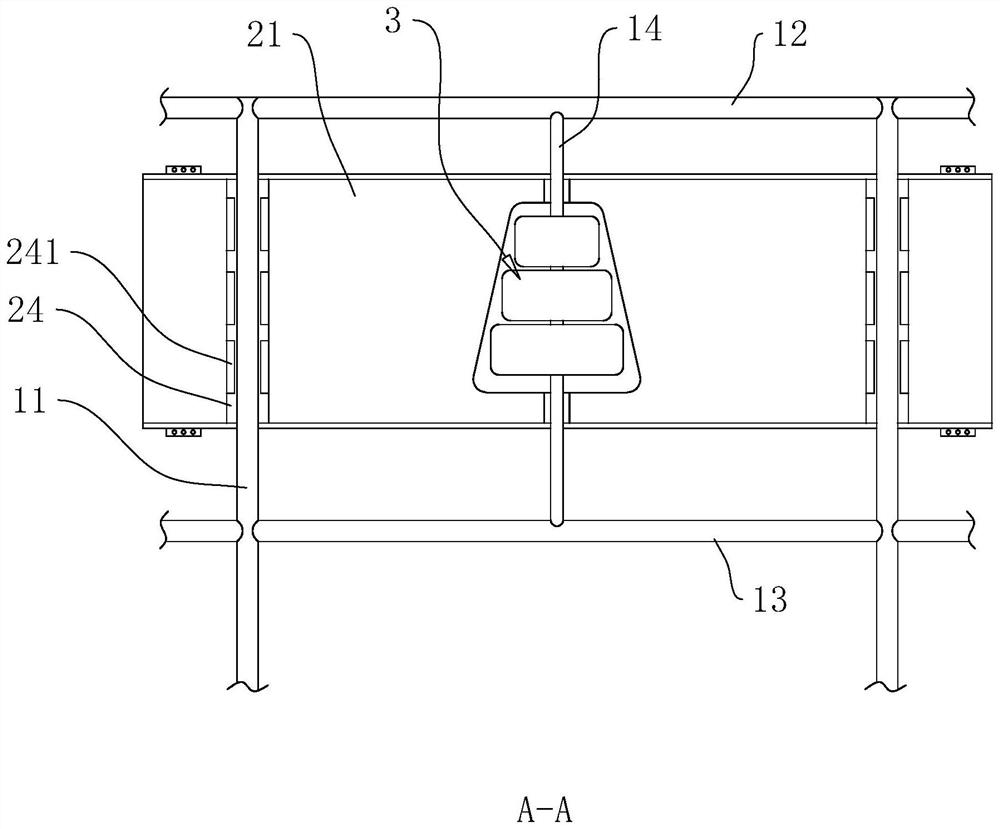

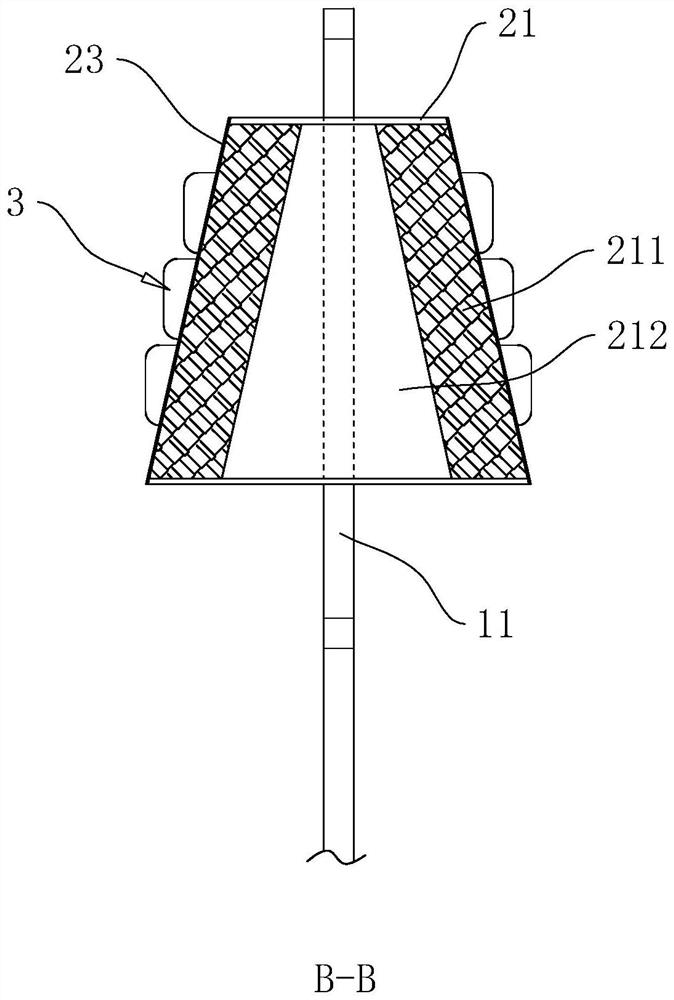

[0039] A group pile type bridge anti-ship collision device, such as figure 1 As shown, it includes structural piles 1 and floating islands 2. Among them, see figure 1 , figure 2 The structural pile 1 includes a plurality of vertical piles 11, an upper beam 12, and a lower beam 13. The vertical piles 11 are provided with a plurality of piles distributed around the bridge 4. The upper beam 12 connects the tops of the adjacent piles 11 horizontally, and the lower beam 13 will be connected to each other. The lower ends of the adjacent piles 11 are connected horizontally, so that the piles 11, the upper beams 12 and the lower beams 13 constitute a group-type structural pile 1, and the bridge 4 is surrounded by the center of the structural piles.

[0040] like figure 1 , figure 2As shown, the floating island 2 is composed of multiple sections of floating boxes 21 connected by connecting pieces 22 . The floating island 2 is installed on the structural pile 1 to surround the bri...

Embodiment 2

[0053] A kind of pile group type bridge anti-ship collision device, the difference from embodiment 1 is that the lubricating glue coated on the surface of roller 3 of embodiment 2 is different, and the lubricating glue preparation method and coating method of the present embodiment are as follows:

[0054] (1) take by weighing the polyvinyl alcohol particle of 40kg, the calcium sulfate of 20kg and the glycerol of 25kg and throw in stirring tank, stirring tank heats up and maintains temperature at 135 ± 2 ℃, after stirring 30min and dispersing uniformly, coating while hot On the surface of the roller, a first sizing layer is formed, and the coating weight of the first sizing layer is 0.4kg / ㎡;

[0055] (2) After the first sizing layer is coated, the roller rotates evenly at 5 r / min to cool down naturally. After the surface temperature of the first sizing layer is naturally cooled to 80±5°C, the composite sulfonic acid is applied to the surface of the first sizing layer. Calcium-...

Embodiment 3

[0058] A kind of pile group type bridge anti-ship collision device, the difference from embodiment 1 is that the lubricating glue coated on the surface of the roller 3 of embodiment 3 is different, and the lubricating glue preparation method and coating method of the present embodiment are as follows:

[0059] (1) take by weighing the polyvinyl alcohol particle of 30kg, the calcium sulfate of 15kg and the glycerol of 20kg and throw in the stirring tank, the stirring tank heats up and maintains temperature at 135 ± 2 ℃, after stirring 30min and dispersing evenly, coating while hot On the surface of the roller, a first sizing layer is formed, and the coating weight of the first sizing layer is 0.4kg / ㎡;

[0060] (2) After the first sizing layer is coated, the roller rotates evenly at 5 r / min to cool down naturally. After the surface temperature of the first sizing layer is naturally cooled to 80±5°C, the composite sulfonic acid is applied to the surface of the first sizing layer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com