Air outlet dust removal pipeline

A technology of pipes and air outlets, applied in the field of dust removal devices, can solve the problems of low efficiency of starch dust separation, affecting the health of staff, and pollution of the surrounding environment, and achieve the effects of easy collection and storage, increased efficiency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

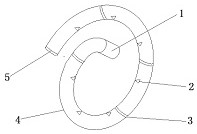

[0018] An air outlet and dust removal pipeline, including a skeleton, a canvas sleeve and a water pipe, the skeleton is a spiral structure composed of a plurality of curved beams and ring beams connected, the canvas sleeve is set on the skeleton; the center of the skeleton extends outwards The pipeline is used as the air outlet, and the outer end of the frame is the air inlet; the frame is provided with a screw hole, and the water mist nozzle is installed on the screw hole, and the canvas sleeve is provided with a small hole corresponding to the water mist nozzle. Connect with the water mist nozzle through the small hole.

[0019] The inner diameter of the air duct cavity gradually decreases from the air inlet to the air outlet. The water mist nozzle is located inside the cavity formed by the skeleton and the canvas sleeve.

[0020] The devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com