Battery module capable of delaying heat diffusion and battery pack

A battery module and thermal diffusion technology, applied in the direction of battery pack parts, secondary batteries, battery cover/end cover, etc., can solve the problem of no eruption direction, insufficient effectiveness of protective measures, and inability to effectively prevent batteries, etc. problem, to achieve the effect of delaying the time of open flames, reducing the degree of violence, and delaying thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

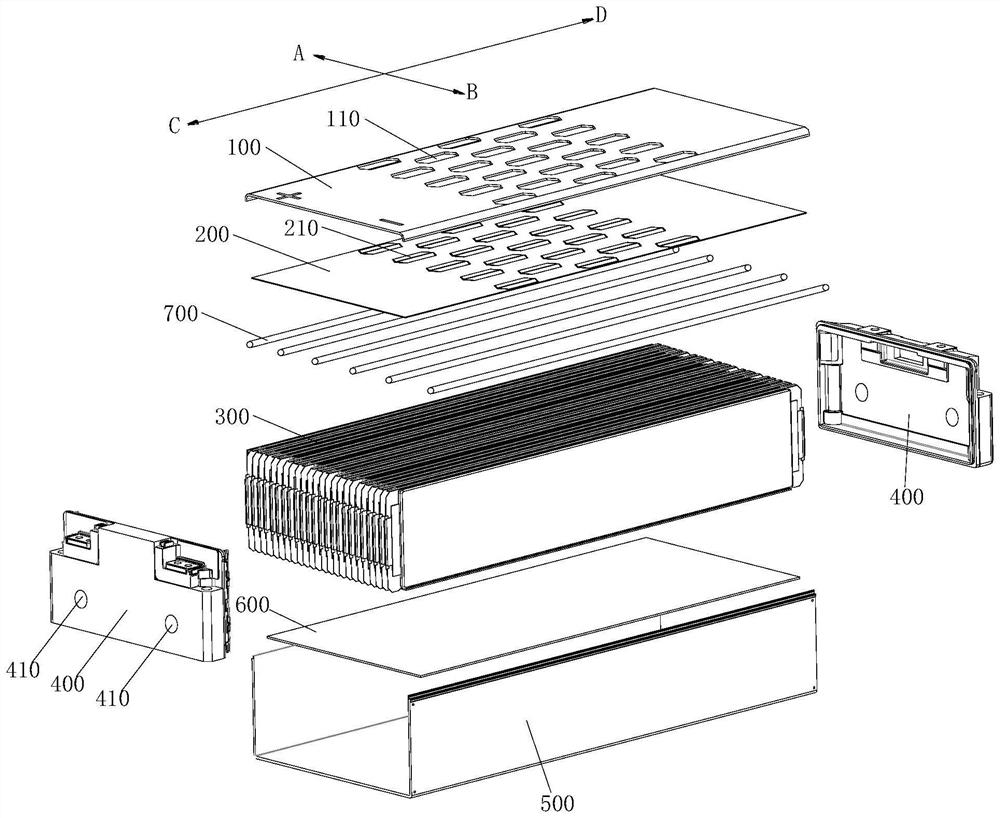

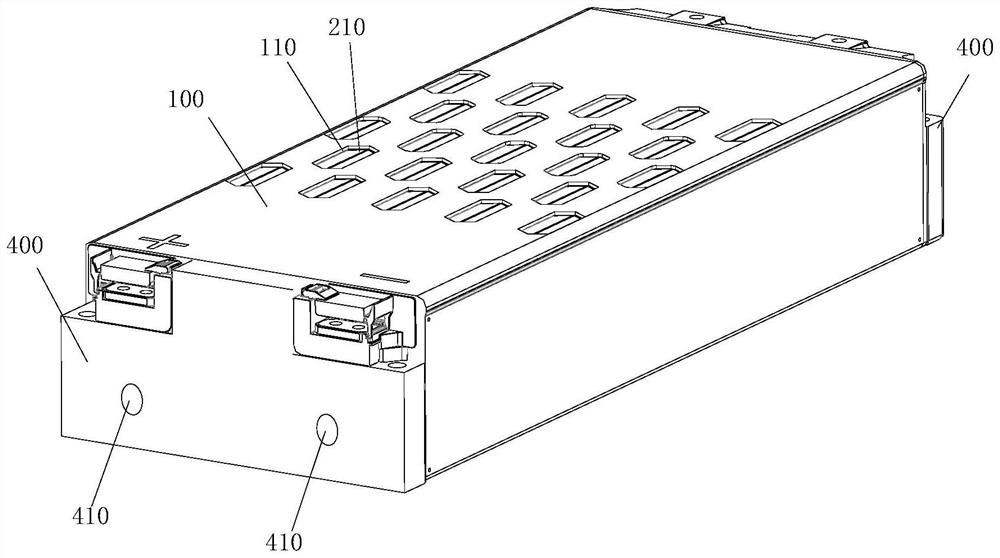

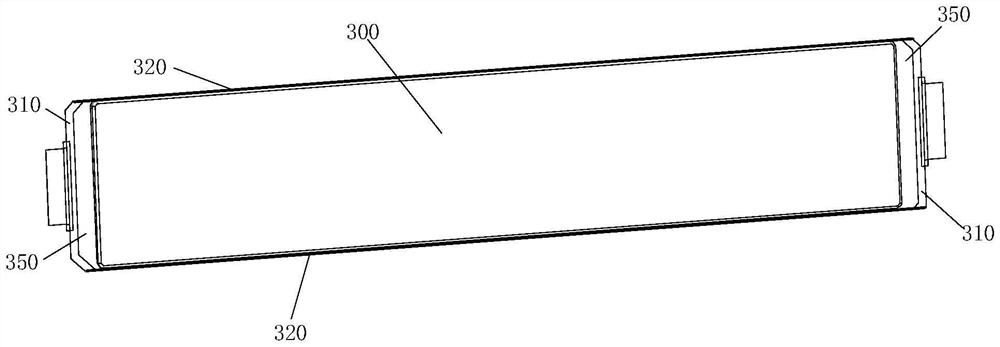

[0047] like Figure 1 to Figure 10 As shown, a battery module for delaying thermal diffusion in this embodiment includes multiple sets of stacked battery cells 340, a module upper cover 100, and a fireproof heat insulation mat 200. The top edge sealing 320 of multiple sets of battery cells 340 is A fireproof heat insulation pad 200 is provided between the module upper covers 100, and a plurality of thermal diffusion openings are provided on the fireproof thermal insulation pad 200, and a device for opening or closing the thermal diffusion openings is connected to the thermal diffusion openings. Door-shaped structure 210; the upper cover 100 of the module is provided with a plurality of thermal diffusion holes 110, and the plurality of thermal diffusion holes 110 are arranged in one-to-one correspondence with a plurality of thermal diffusion openings; A closed thermal diffusion channel is formed between the thermal pads 200, and the thermal diffusion channel corresponds to at l...

Embodiment approach 1

[0058] Embodiment 1, each battery cell has only one battery cell, and the shoulder 340a where the top edge sealing 320 of each battery cell 340 is located can be sealed and connected to the fireproof heat insulation pad 200 through the sealing strip 700, so that each battery cell Each cell 340 corresponds to a thermal diffusion channel, which is beneficial to delaying the thermal diffusion time of a single battery cell, and finally delaying the thermal runaway time of the entire battery module.

Embodiment approach 2

[0059] Embodiment 2, such as Figure 9 and Figure 10 As shown, each group of cells contains two cells, and sealing strips 700 can be provided on the shoulders on the left and right sides of the top edge of each group of cells, that is, between the top edges of two adjacent groups of cells. One sealing rubber strip 700, one sealing rubber strip 700 is provided for every two batteries, which is convenient for production under the premise of delaying the time of thermal runaway.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com