Bearing motor

A bearing motor and inner bearing technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as lack of strong support from back-end equipment manufacturers, and achieve obvious energy-saving effects, increase startup speed, and extend battery life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

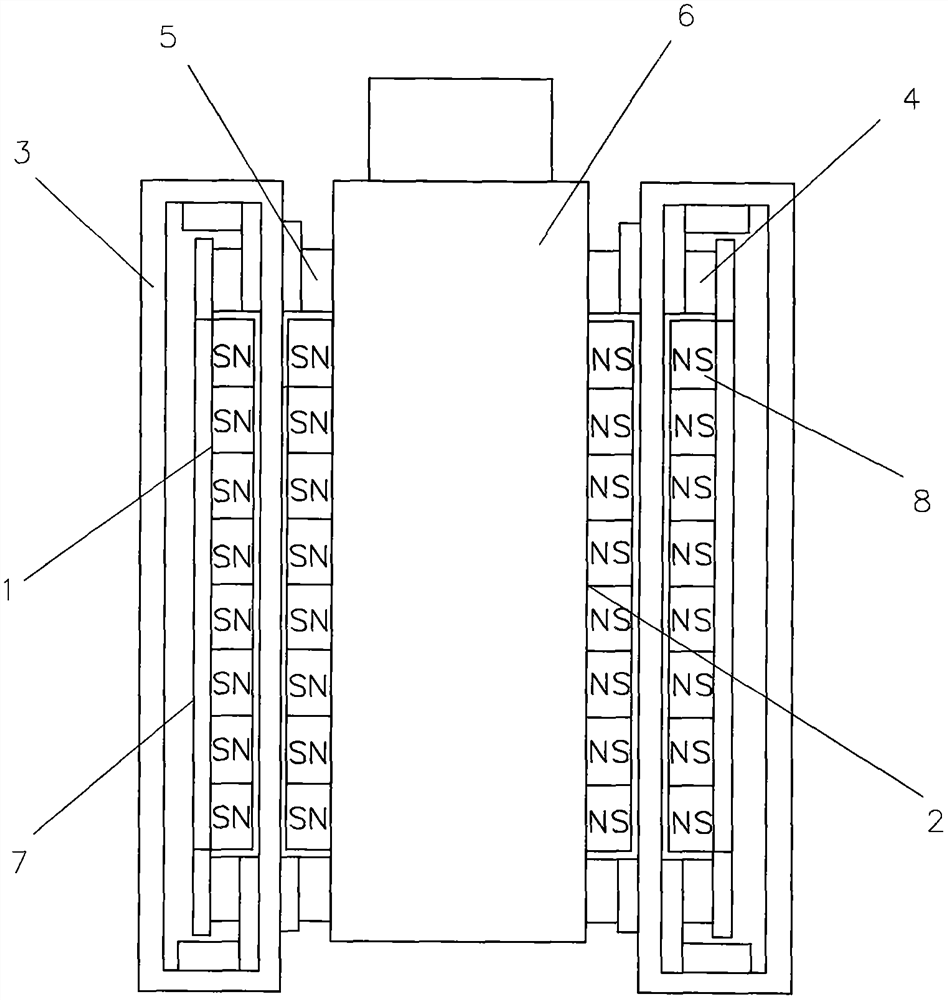

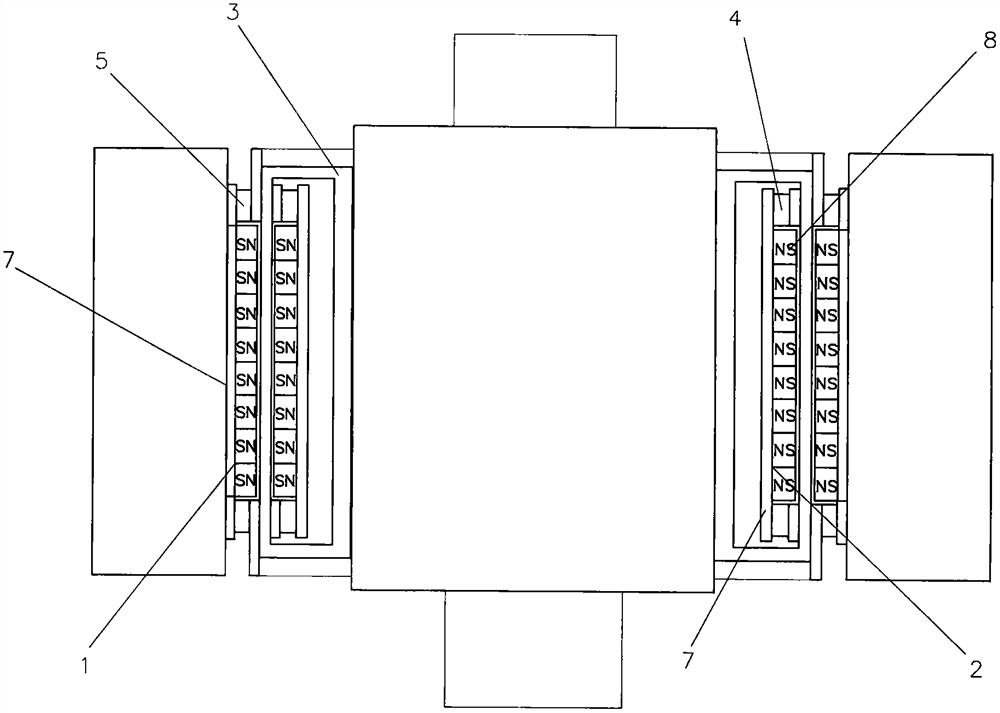

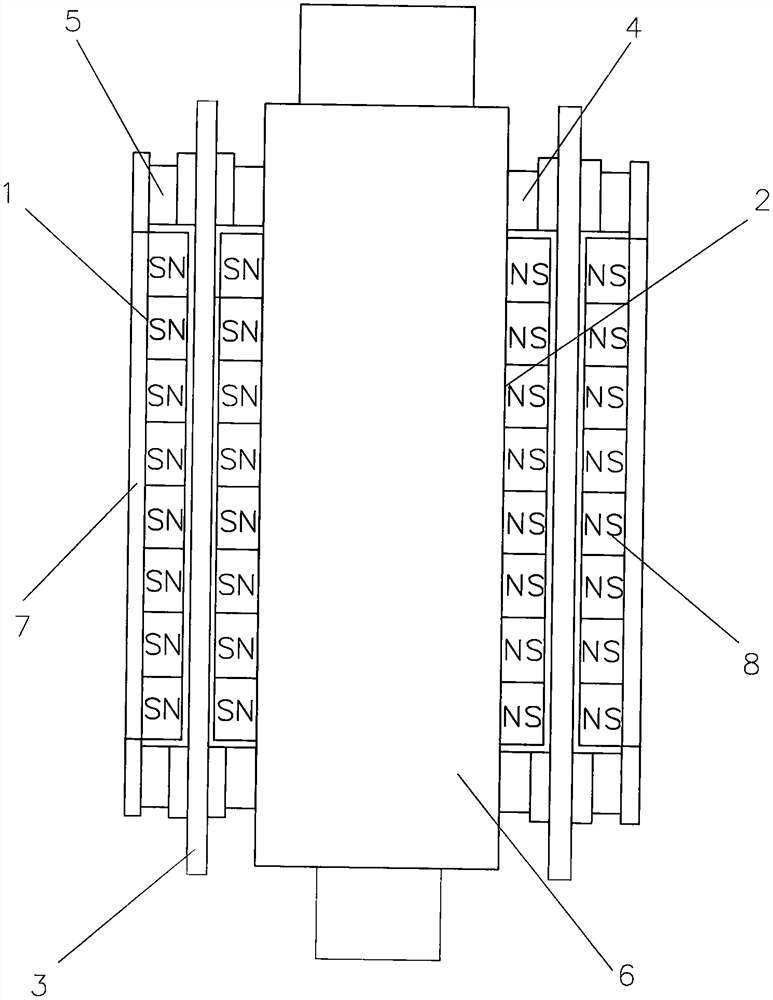

[0033] Implementation column 1, such as figure 1 and Figure 4 As shown in: a bearing motor, including an outer rotor 1, an inner rotor 2, a wire 3, an inner bearing 4 and an outer bearing 5, it is characterized in that: in the cavity of the outer rotor 1, an inner rotor 2 is arranged, and the outer The rotor 1 and the inner rotor 2 are coaxial, the outer rotor 1 and the inner rotor 2 are both magnets, and there is a certain gap between the inner wall of the outer rotor 1 and the outer wall of the inner rotor 2 Magnetic cavity, the magnetic cavity is a uniform centripetal magnetic field, the outer rotor 1 is a magnet composed of several permanent magnets with the same radial magnetic field arranged on the inner wall of the circular iron cylinder 7, the permanent magnet 8 The magnetic field placement directions are all radial N-S, or all radial S-N, and the inner rotor 2 is cylindrical, and the inner rotor is arranged on the outer surface of the circular iron rod 6. Magnets c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com