Heat dissipation device and frequency conversion cabinet

A technology of a heat dissipation device and a heat dissipation plate, which is applied in the field of electric motors, can solve the problems of large flow resistance of cooling flow channels and poor heat dissipation uniformity, and achieves the advantages of improving heat exchange efficiency, ensuring heat dissipation uniformity, and reducing the thermal resistance of flow channels. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

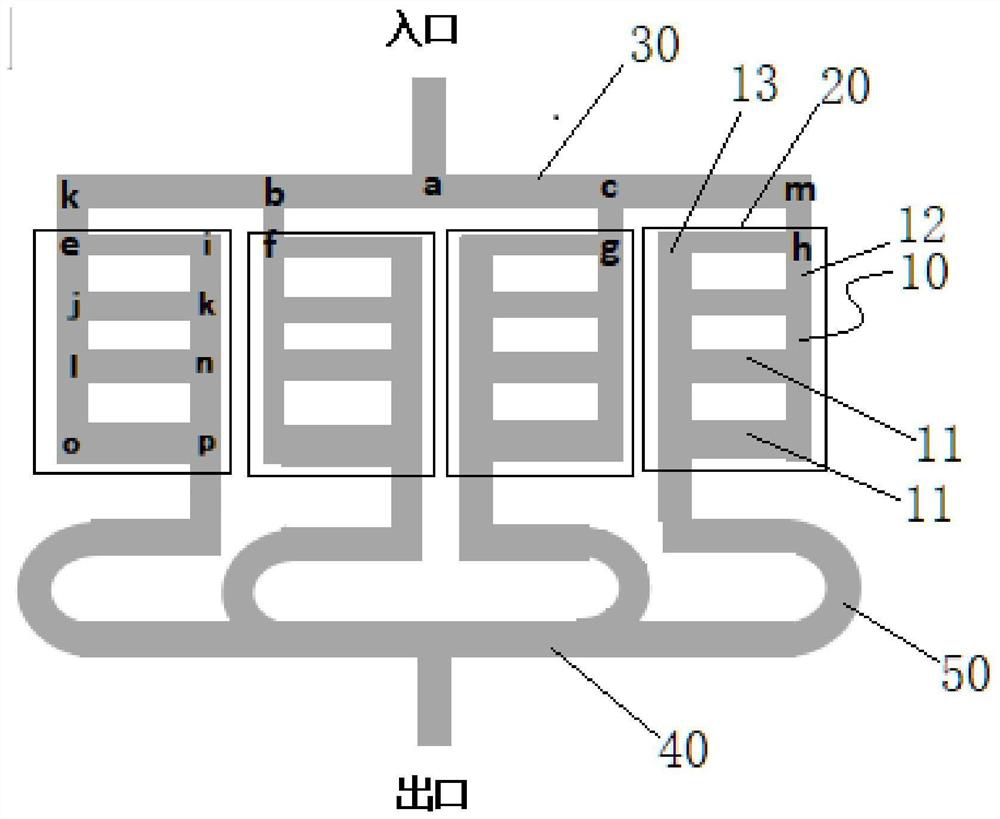

[0020] In the existing liquid cooling method, a flat-plate heat sink is usually used, and the cooling channels between multiple power components (such as: IGBT) are sequentially connected in series, and the cooling liquid enters the bottom of the power components (such as: IGBT) in sequence. The cooling flow channel of the first power component (such as: IGBT) is much better than that of the subsequent components, resulting in the worst cooling effect of the last power component (such as: IGBT), which becomes the bottleneck of heat dissipation. : IGBT) produces a weakening phenomenon of working capacity, and, as far as a single power element (such as: IGBT) is concerned, due to the series connection of cooling channels, the temperature on the power element (such as: IGBT) is also different, resulting in uneven heat dissipation.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com