Dust removal and desulfurization process for industrial waste gas

A technology for industrial waste gas and desulfurization process, applied in gas treatment, dispersed particle filtration, membrane technology, etc., can solve problems such as increasing treatment costs, polluting the atmospheric environment, and clogging the inner wall of pipelines, reducing treatment costs, improving treatment efficiency, Improve the effect of contact mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0025] An industrial waste gas dedusting and desulfurization process is characterized in that it comprises the following steps:

[0026] S1. Design a waste gas dedusting and desulfurization device;

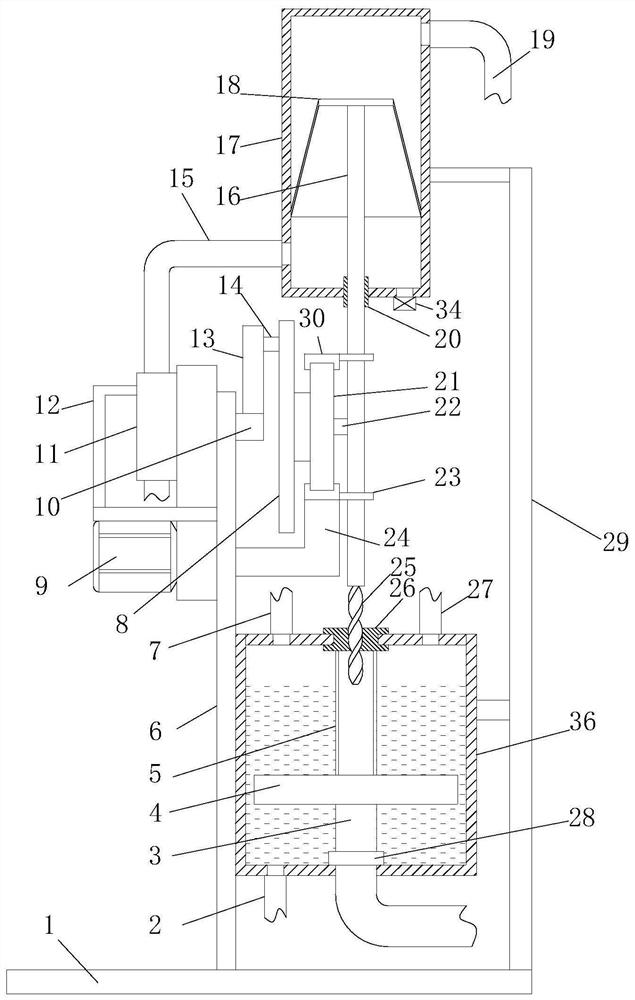

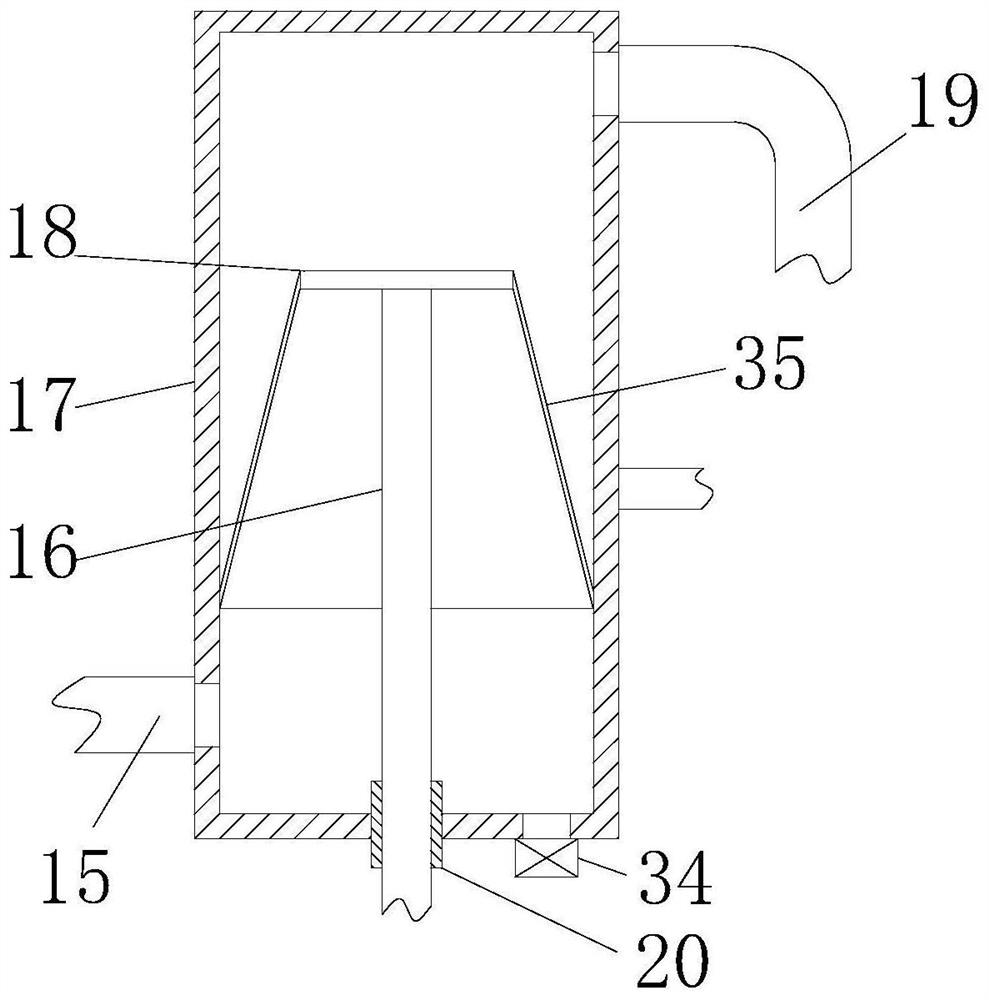

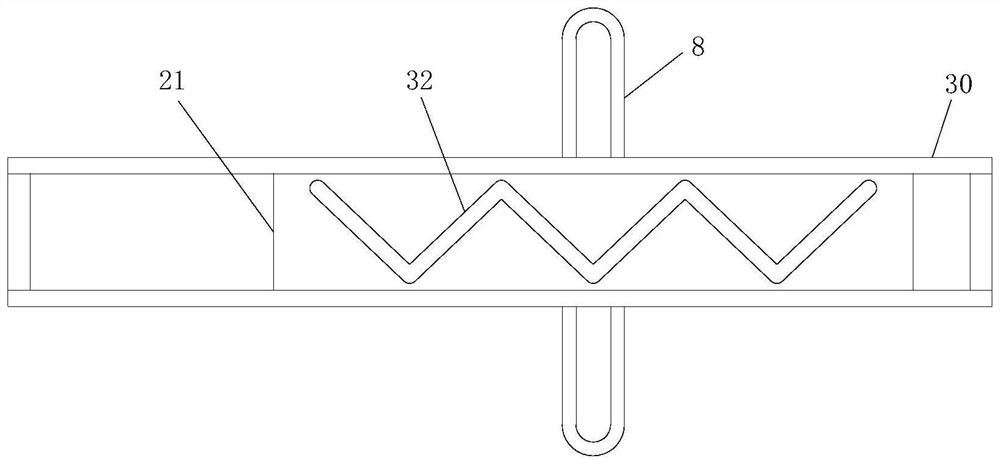

[0027] see Figure 1 to Figure 5 , an exhaust gas dedusting and desulfurization device includes a base 1, and also includes:

[0028] The pumping mechanism is used to convey industrial waste gas for dust removal and desulfurization treatment, and the pumping mechanism is arranged on the base 1;

[0029] The dust filter mechanism is used to remove dust from the industrial waste gas transported by the pump mechanism, and the dust filter mechanism can be automatically placed and blocked under the drive of the pump mechanism, and the dust filter mechanism is arranged on the base 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com