Blending tank with heating function for lubricating oil production

A lubricating oil and blending technology, which is applied to mixers with rotating stirring devices, transportation and packaging, chemical instruments and methods, etc., can solve the problems of affecting the performance of finished products, the decline of finished product performance, and large temperature difference changes, so as to ensure stable performance , Prevent violent fluctuations and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

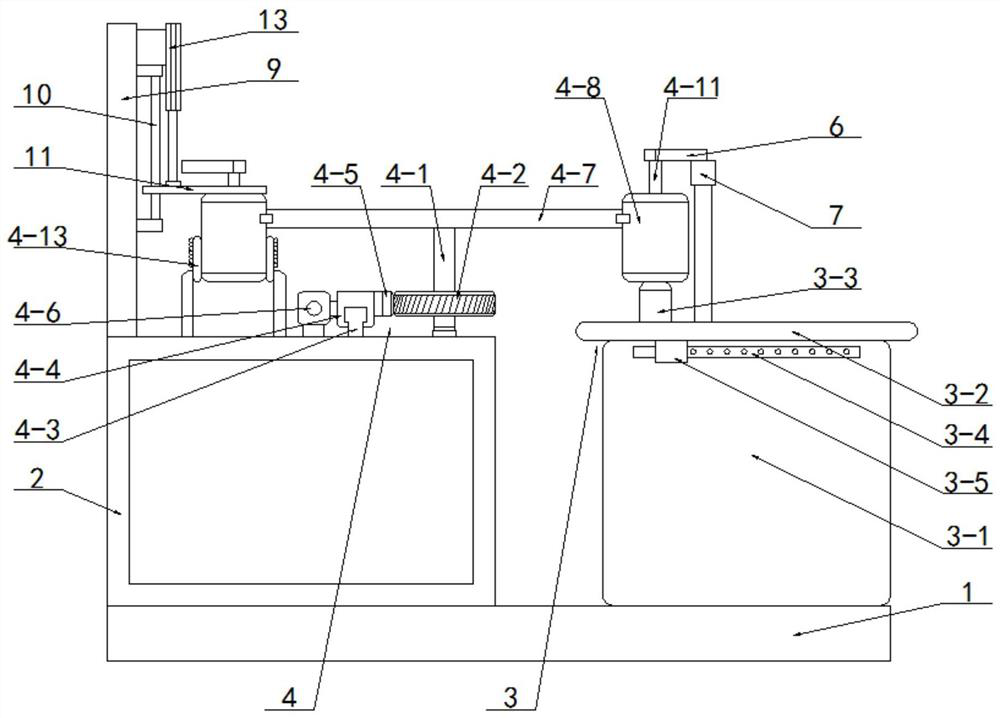

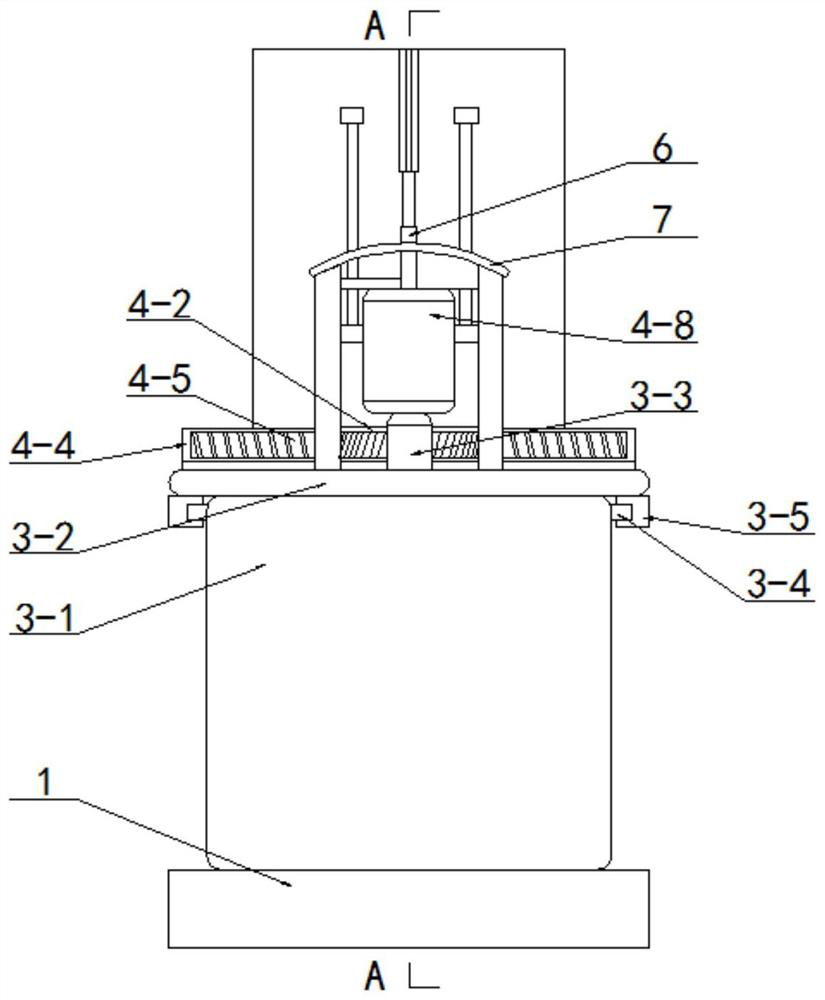

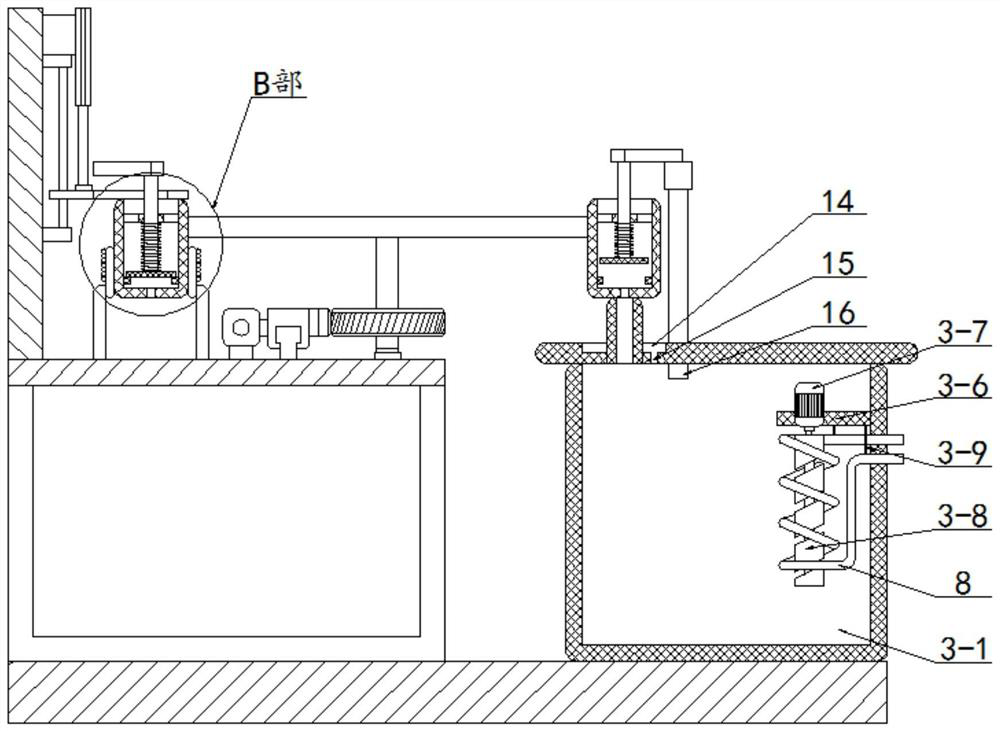

[0026] The present invention will be further described below with reference to the accompanying drawings.

[0027] See Figure 1 - Figure 6 As shown, the specific embodiment includes a base 1, a stirring assembly 3, a preheating assembly 4, wherein the agitation assembly 3 is fixed to the base 1, and the base 1 is fixed to the base 1, and the bracket 2 is disposed at the left of the stirring assembly 3. On the side, the preheating assembly 4 is fixed to the bracket 2, and the outlet end of the preheating assembly 4 is disposed above the inlet end of the agitation assembly 3;

[0028]The stirring assembly 3 comprises a stirred tank 3-1, a No. 1 panel 3-2, a bracket 2, a waterproof motor 3-7, a spiral stirring roller 3-8, a hot wire 3-9, wherein the mixture 3 -1 riveting on the base 1, the upper end opening of the stirred kettle 3-1, the upper end of the stirrer 3-1 is covered with one panel 3-2, and the No. 1 panel 3-2 is wearing fixed tube 3-3 5 Slide is placed on a rail 3-4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com