Monatomic nano-enzyme as well as preparation method and application thereof

A nano-enzyme, atomic technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low single-atom loading and limit the application of single-atom nanozymes, and achieve simple and easy preparation methods and components. obtainable and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

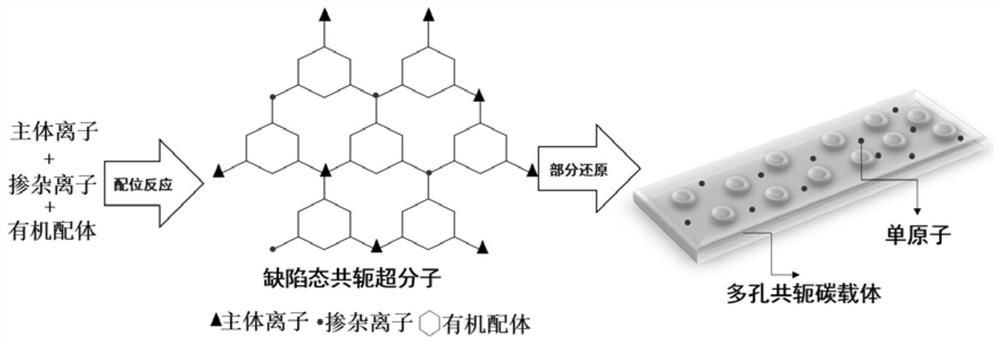

[0052] Embodiment 1: the preparation of Fe single atom nanozyme

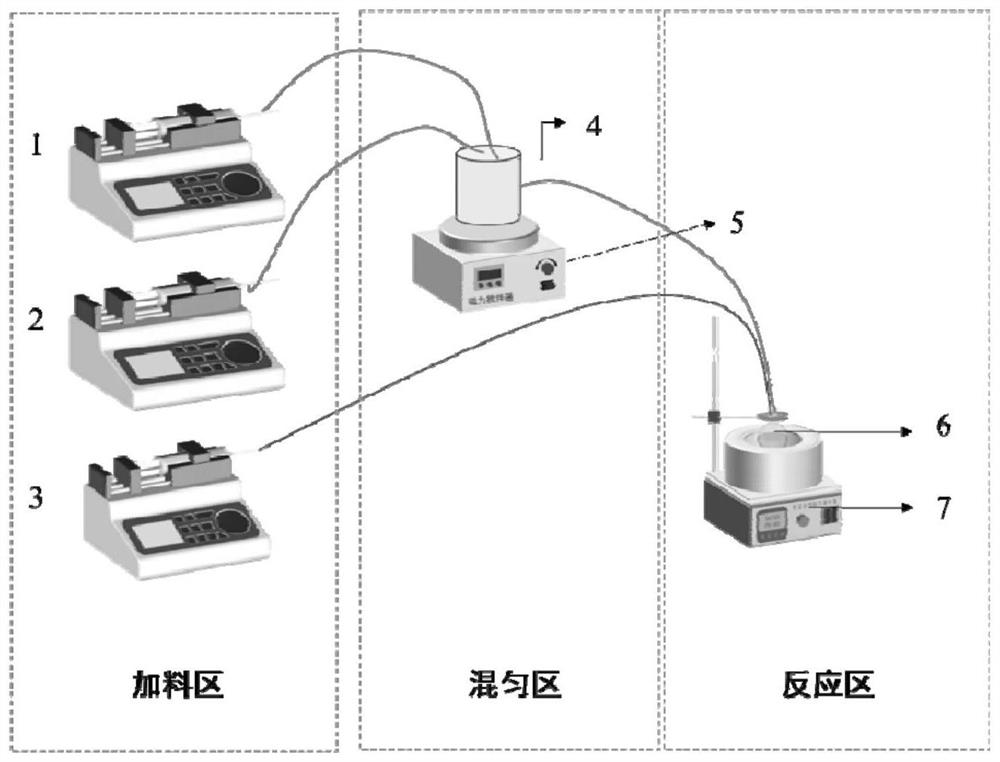

[0053] 0.32g Fe(NO 3 ) 3 9H 2 O was dissolved in 20 mL of methanol to obtain 0.04 mol L -1 Ferric nitrate methanol solution (solution A); 11.9g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 1000 mL of methanol to obtain 0.04 mol L -1 Zinc nitrate methanol solution (solution B); 20.1g methylimidazole was dissolved in 1000mL methanol to obtain 0.25mol L -1 Methanol solution of methylimidazole (Solution C). Put the above solution into figure 2 The feeding area of the microfluidic reaction device shown.

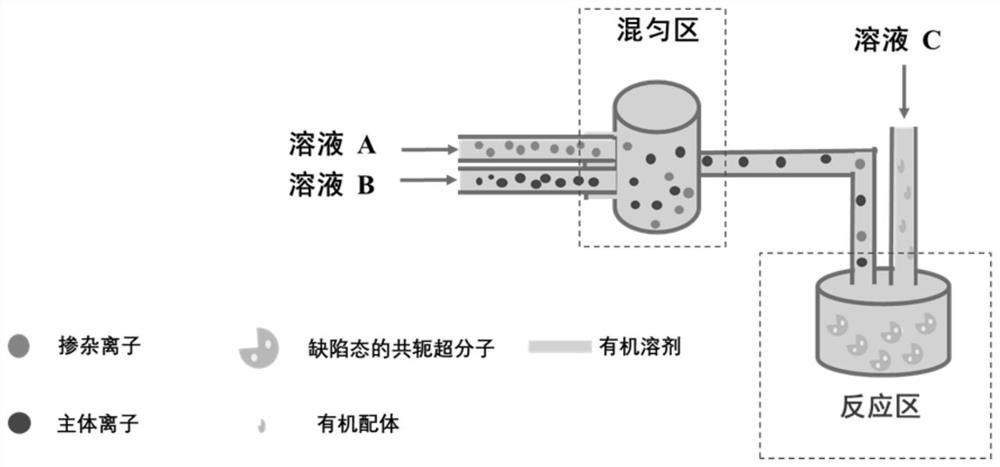

[0054] First pass solution A and solution B into the transition chamber, stir and mix at a speed of 1000r / min, then pass the mixed metal ion solution and solution C into the microfluidic reaction chamber, and stir at a speed of 500r / min , keep the reaction at 60°C to obtain the conjugated supramolecule in the defect state, the reaction process is as follows image 3 shown. Set the flow rate of solution A to 0...

Embodiment 2

[0059] Embodiment 2: Preparation of Co single atom nanozyme

[0060] Prepare 0.125mol·L -1 Cobalt acetate N,N dimethylformamide solution (solution A) and 0.125mol·L -1 Zinc acetate N,N dimethylformamide solution (solution B) and 0.5mol L -1 1,1'-ferrocenecarboxylic acid N,N dimethylformamide solution (Solution C).

[0061] First pass solution A and solution B into the transition chamber, stir and mix at a speed of 1200r / min, then pass the mixed metal ion solution and solution C into the microfluidic reaction chamber, and stir at a speed of 800r / min , keep the reaction at 100°C to obtain the conjugated supramolecule in the defect state, the reaction process is as follows image 3 shown. Set the flow rate of solution A to 0 μL min -1 , 80 μL·min -1 , 160μL·min -1 , 240μL·min -1 , the four different flow rates correspond to the Co atom loadings from 0%, 4%, 8%, and 12% respectively; the corresponding solution B flow rate is set to 2000μL·min -1 , 1920μL·min -1 , 1840μL·...

Embodiment 3

[0066] Embodiment 3: the preparation of Mg single-atom nanozyme

[0067] Prepare 0.35mol·L -1 Magnesium chloride methanol solution (solution A), 0.2mol L -1 zinc chloride methanol solution (solution B) and 0.5mol L -1 4,4-bipyridine methanol solution (Solution C).

[0068] First pass solution A and solution B into the transition chamber, stir and mix at a speed of 800r / min, then pass the mixed metal ion solution and solution C into the microfluidic reaction chamber, and stir at a speed of 600r / min , keep the reaction at 60°C to obtain the conjugated supramolecule in the defect state, the reaction process is as follows image 3 shown. Set the flow rate of solution A to 0 μL min -1 , 80 μL·min -1 , 160μL·min -1 , 240μL·min -1 , four different flow rates correspond to the Mg atomic loads from 0%, 4%, 8%, and 12% respectively; the corresponding solution B flow rate is set to 2000μL·min -1 , 1920μL·min -1 , 1840μL·min -1 , 1760μL·min -1 ; The flow rate of solution C was...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap